A connection device for dissimilar materials based on multi-leg connectors

A technology of dissimilar materials and connectors, which is applied in welding/welding/cutting items, welding equipment, manufacturing tools, etc., can solve the problem of difficult welding and welding quality of dissimilar materials, and achieves great differences in physical and chemical properties. Effects of performance and torsional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiment of the present invention solves the technical problems of difficult welding of dissimilar materials and poor welding quality in the prior art by providing a dissimilar material connection device based on multi-legged connectors.

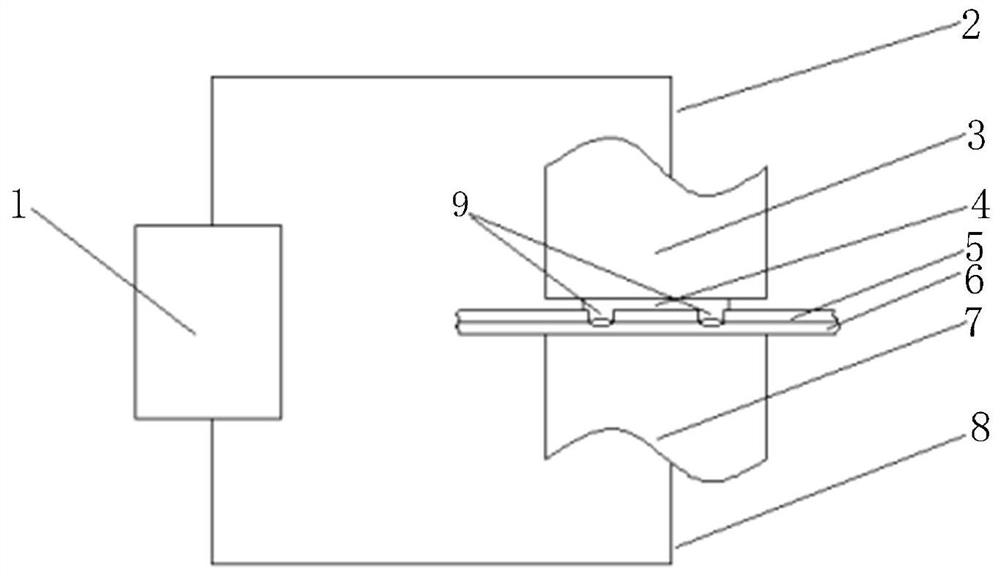

[0024] see figure 1 , The embodiment of the present invention provides a dissimilar material welding device based on a multi-leg connector, including: a power source 1 , an upper electrode 3 , a multi-leg connector, an upper sample 5 , a lower sample 6 and a lower electrode 7 .

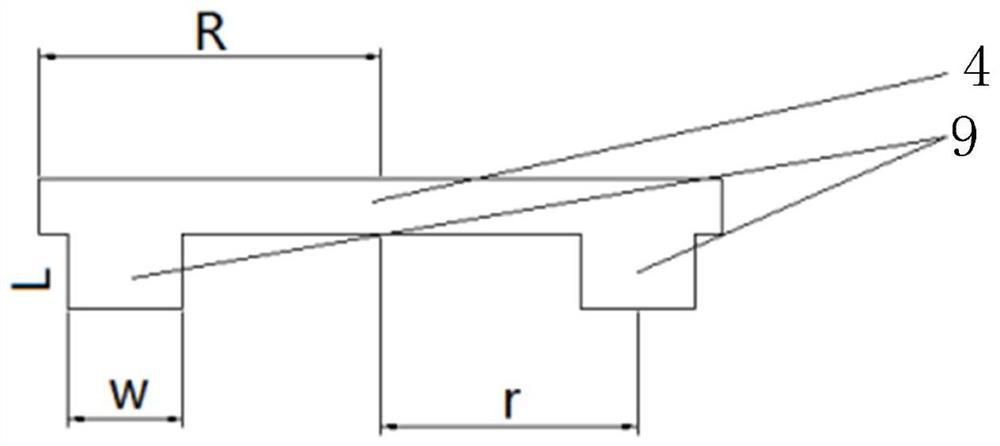

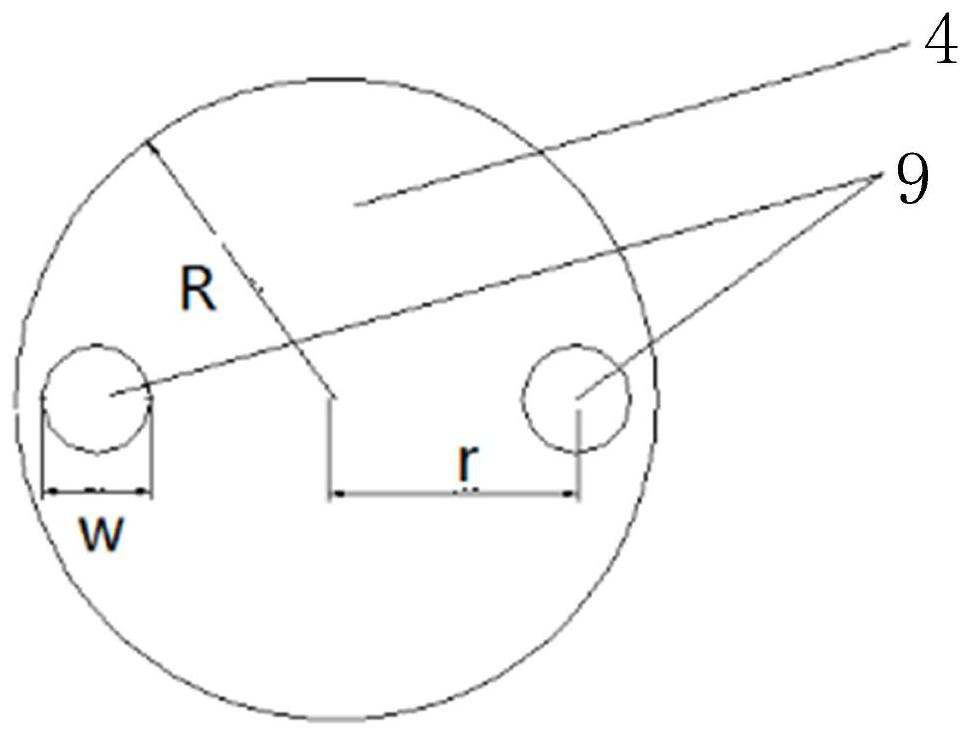

[0025] Wherein, one end of the power supply 1 is connected to the upper electrode 3, and the upper electrode 3 is arranged above the lower electrode 7; the upper sample 5 and the lower sample 6 are arranged between the upper electrode 3 and the lower electrode 7, and the upper sample 5 is pasted The lower sample 6 is attached to the lower electrode 7; the lower electrode 7 is connected to the other end of the power supply 1. Among them, the multi-leg c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com