Dissimilar material connection device based on structural glue and auxiliary sample

A technology of dissimilar materials and connecting devices, applied in welding equipment, welding/welding/cutting items, resistance welding equipment, etc., can solve problems such as difficult to achieve effective connection and low welding strength, and achieve convenient acquisition, low cost, and device operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

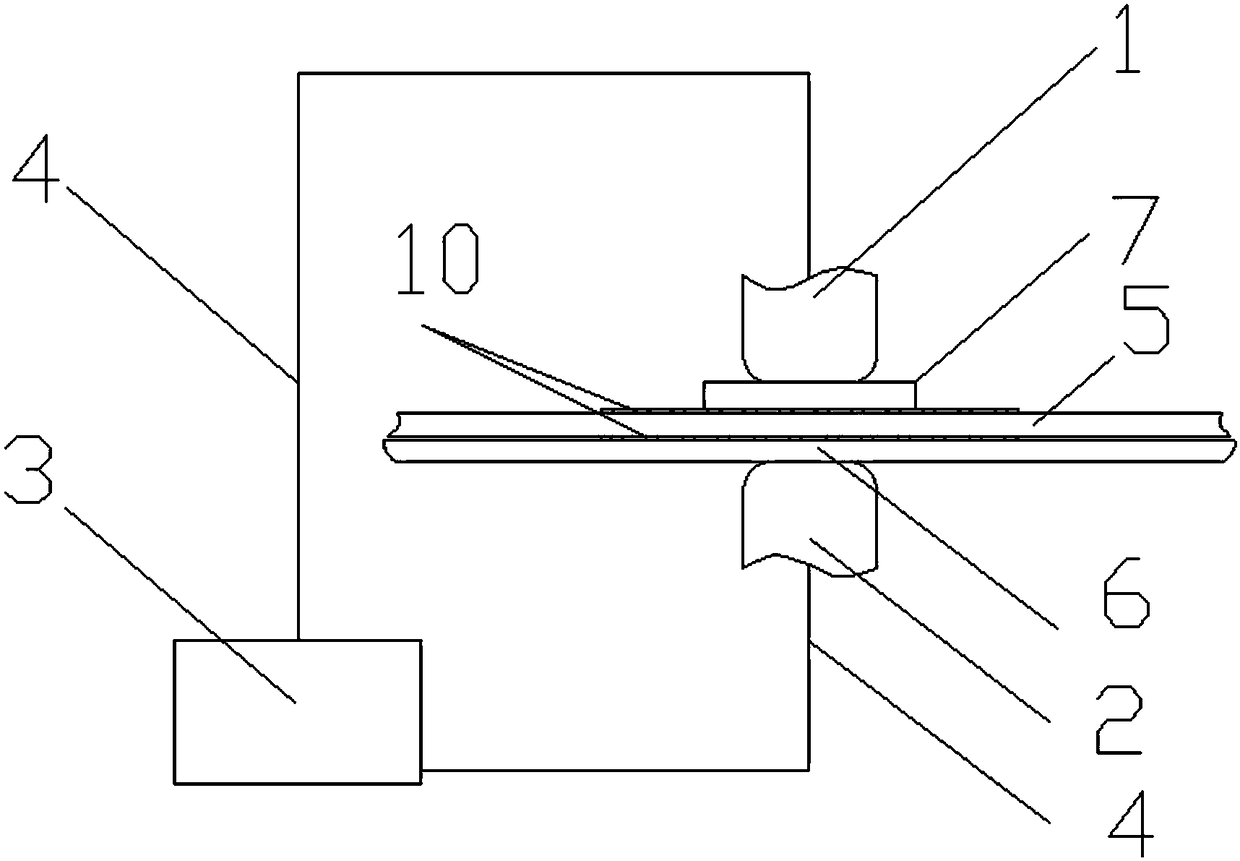

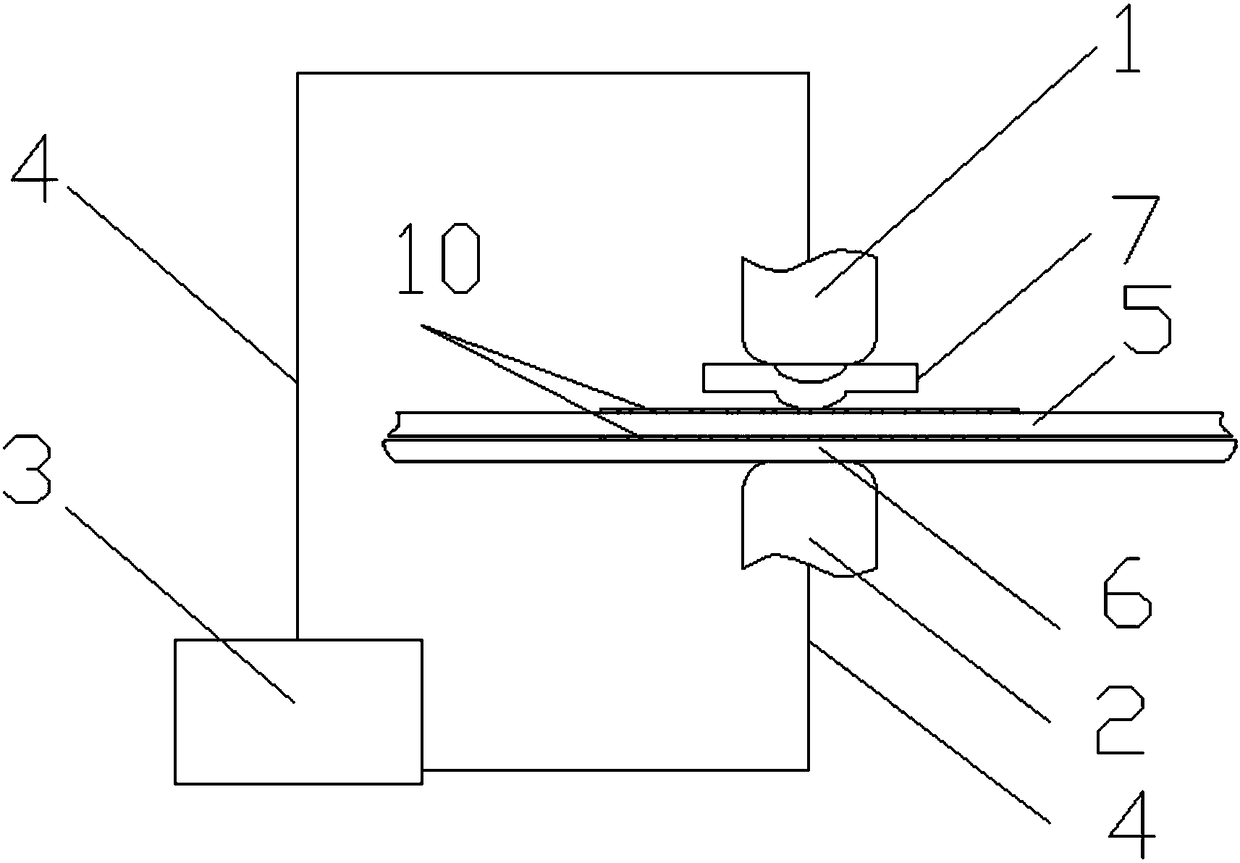

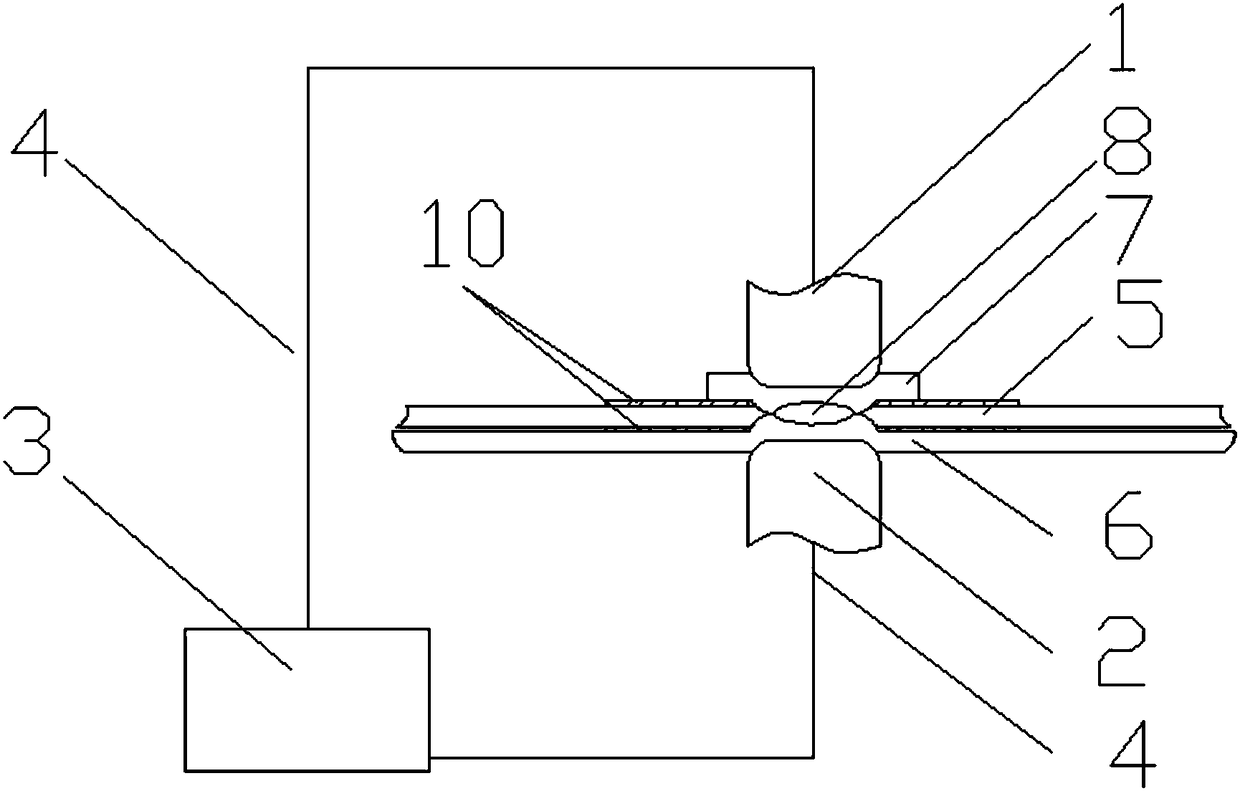

[0026] A device for connecting dissimilar materials based on structural glue and auxiliary samples, including an upper electrode 1, a lower electrode 2, a power supply 3, a conductor 4, an upper sample 5, a lower sample 6, an auxiliary sample 7 and a structural adhesive 10. The upper electrode 1 and the lower electrode 2 are connected to the power supply 3 through the conductor 4, the lower sample 6 is located between the lower electrode 2 and the upper electrode 1, the upper sample 5 is located between the lower sample 6 and the upper electrode 1, and the auxiliary test The sample 7 is located between the upper sample 5 and the upper electrode 1, the upper sample 5 has structural glue 10 on one or both sides of the position to be welded, and there is a weld nugget 8 between the auxiliary sample 7 and the lower sample 6.

[0027] The upper sample 5 is a 5-series aluminum alloy material with a thickness of 1mm; the lower sample 6 is a 400Mpa low-alloy high-strength steel materia...

Embodiment 2

[0046] A device for connecting dissimilar materials based on structural glue and auxiliary samples, including an upper electrode 1, a lower electrode 2, a power supply 3, a conductor 4, an upper sample 5, a lower sample 6, an auxiliary sample 7 and a structural adhesive 10. The upper electrode 1 and the lower electrode 2 are connected to the power supply 3 through the conductor 4, the lower sample 6 is located between the lower electrode 2 and the upper electrode 1, the upper sample 5 is located between the lower sample 6 and the upper electrode 1, and the auxiliary test The sample 7 is located between the upper sample 5 and the upper electrode 1, and there is structural adhesive 10 on one or both sides of the upper sample 5 to be welded, and finally a weld nugget 8 is formed between the auxiliary sample 7 and the lower sample 6.

[0047] The auxiliary sample 7 is a disc with a diameter of 20 mm and a thickness of 1 mm, and a protrusion is prefabricated on the surface of the ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com