Copper-aluminum joint with high mechanical strength

A technology of mechanical strength, copper-aluminum joints, applied in mechanical equipment, non-removable pipe connections, pipes/pipe joints/pipe fittings, etc. Ingenious design, enhanced mechanical strength, and the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

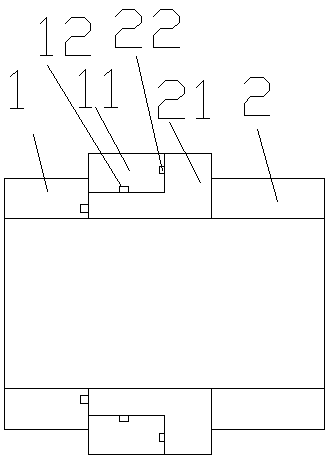

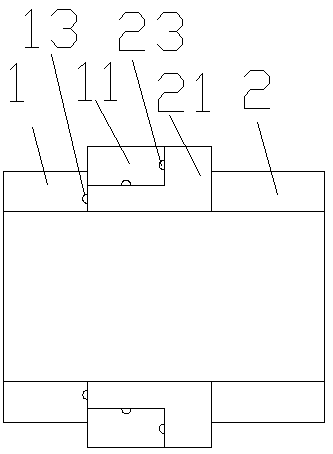

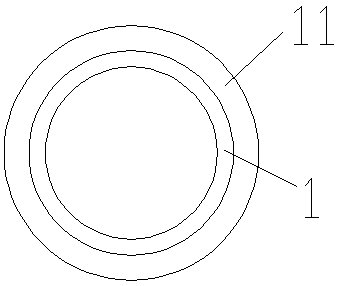

[0017] Such as Figure 1-4 As shown, a copper-aluminum joint with high mechanical strength includes a copper tube 1 and an aluminum tube 2 .

[0018] The end of the copper pipe 1 is provided with a first connecting portion 11, and the first connecting portion 11 is an L-shaped structure arranged laterally.

[0019] The end of the aluminum tube 2 is provided with a second connecting portion 21, and the second connecting portion 21 is an L-shaped structure arranged laterally.

[0020] The first connecting part 11 and the second connecting part 21 are arranged oppositely. The first connecting part 11 and the second connecting part 21 form a rectangular structure. The positioning mechanism is connected by resistance spot welding between the first connecting portion 11 and the second connecting portion 21 .

[0021] The positioning structure includes a matched first rectangular slot 12 and a first rectangular block 22 , the first rectangular slot is set on the outer side of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com