A deviation-correcting automatic locking screw machine for computer cases

An automatic locking screw machine, computer case technology, applied in screwdrivers, power tools, wrenches, etc., can solve the problems of high labor consumption, circuit board jitter, screw floating, etc., and achieve the effect of improving quality and avoiding floating height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

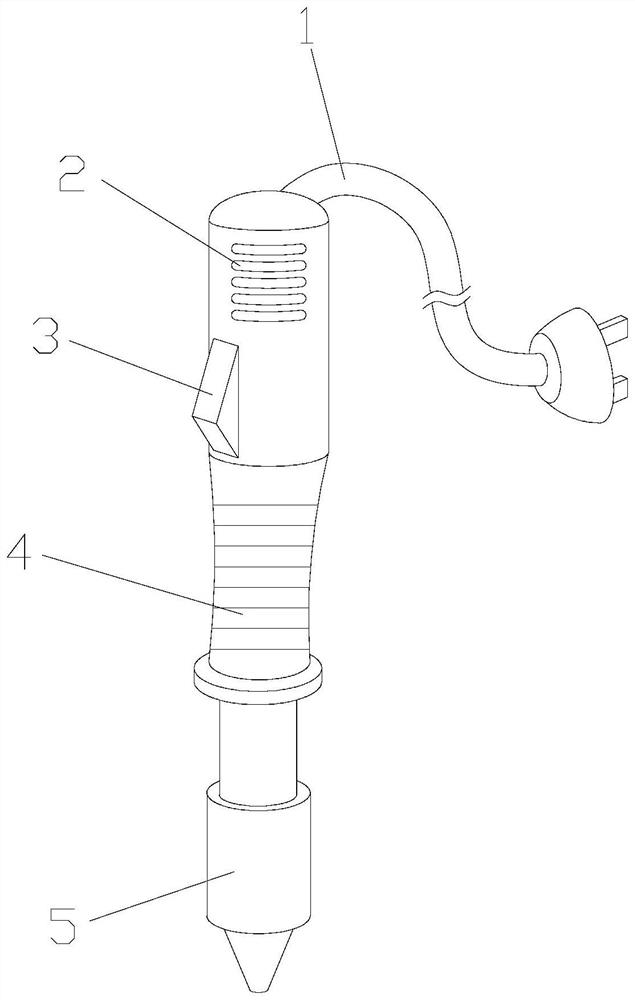

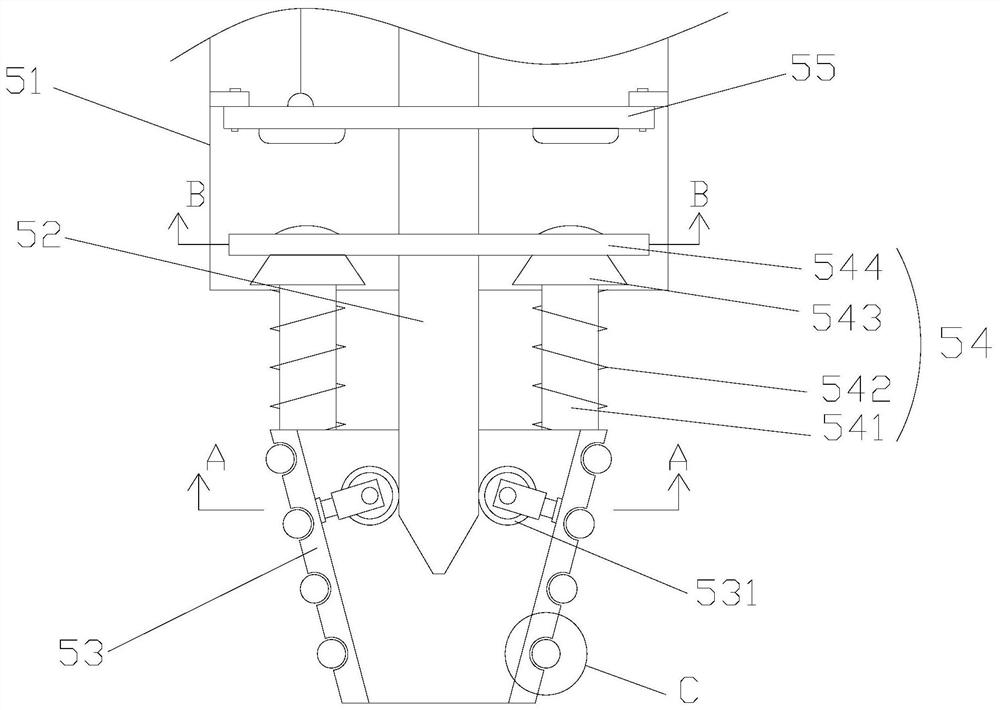

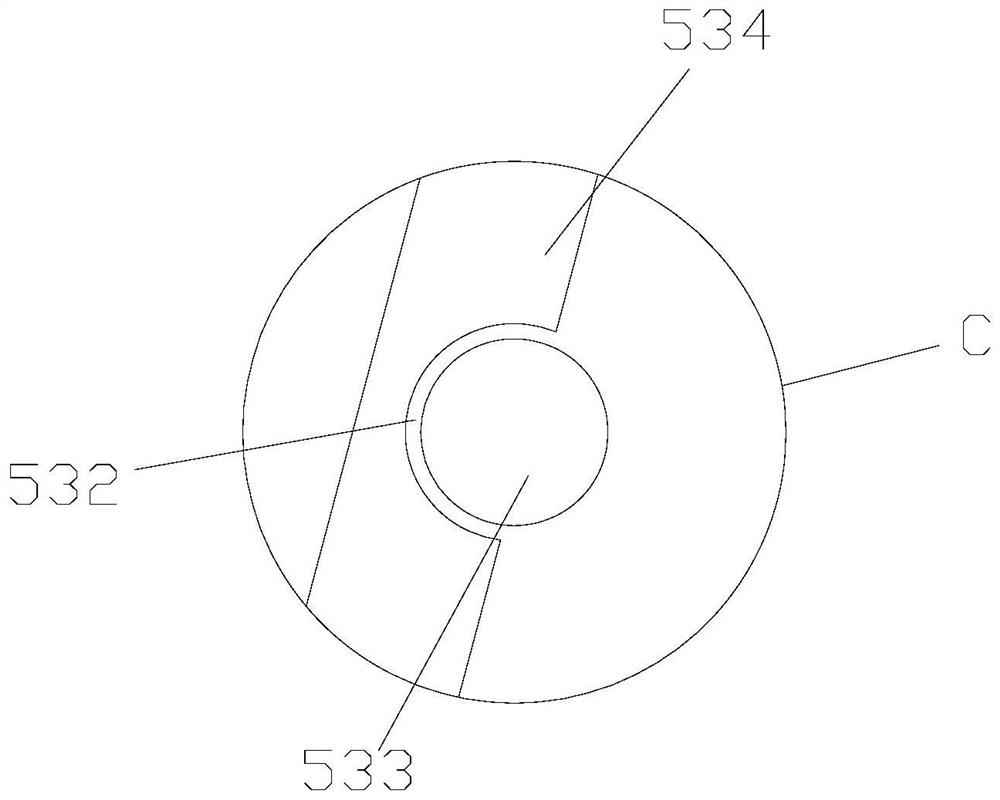

[0023] see Figure 1-Figure 2 , the present invention provides an automatic locking screw machine that can be corrected for a computer case, and its structure includes a power plug 1, a heat dissipation hole 2, a forward and reverse button 3, a screw machine main body 4, and a deviation correcting device 5. The power plug 1 is embedded Set on the top of the screw machine main body 4, the heat dissipation holes 2 are evenly distributed on the top of the front of the screw machine main body 4, the forward and reverse button 3 is located at the lower left corner of the heat dissipation holes 2 on the front of the screw machine main body 4, and the deviation correction device 5 is mechanically connected to the bottom of the main body 4 of the screw machine. The deviation correction device 5 is composed of a deviation correction device protective cover 51, an electric screwdriver 52, a deviation correction device structure 53, a screw machine driving structure 54, and a circuit boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com