External touch screen assembly structure and robot teaching device

An assembly structure and touch screen technology, which is applied in the direction of manipulators and manufacturing tools, can solve the problems of narrowing the visual angle range of the touch screen, high protection level of the shell of the teaching pendant, and cumbersome installation of the built-in touch screen, so as to improve the overall appearance effect, Expand the range of visual perception angles and improve the effect of operating experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

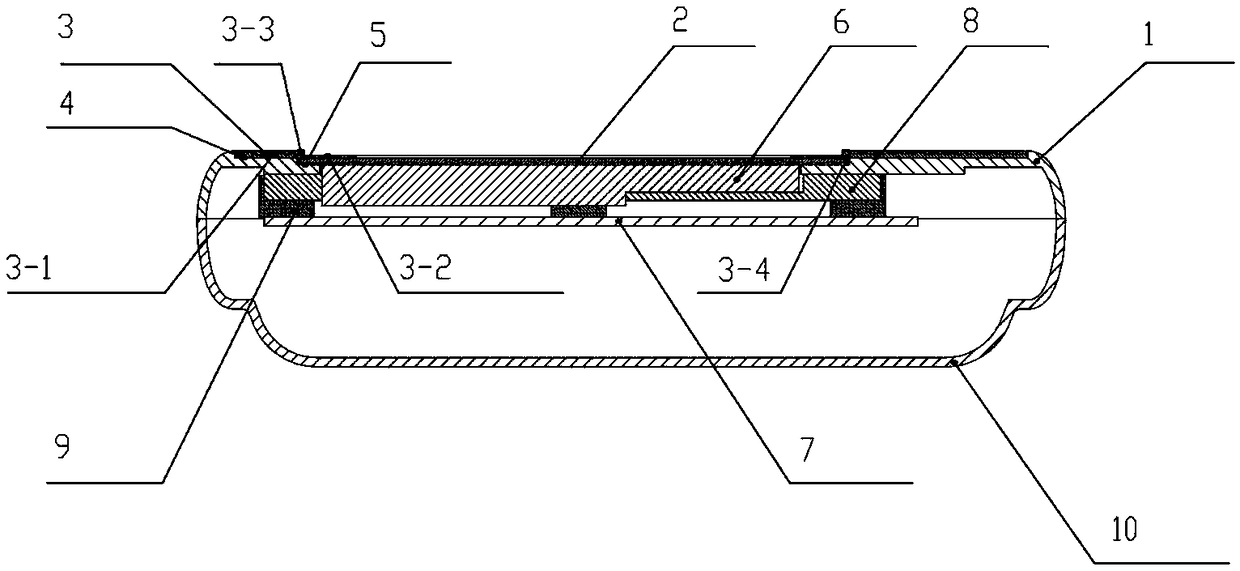

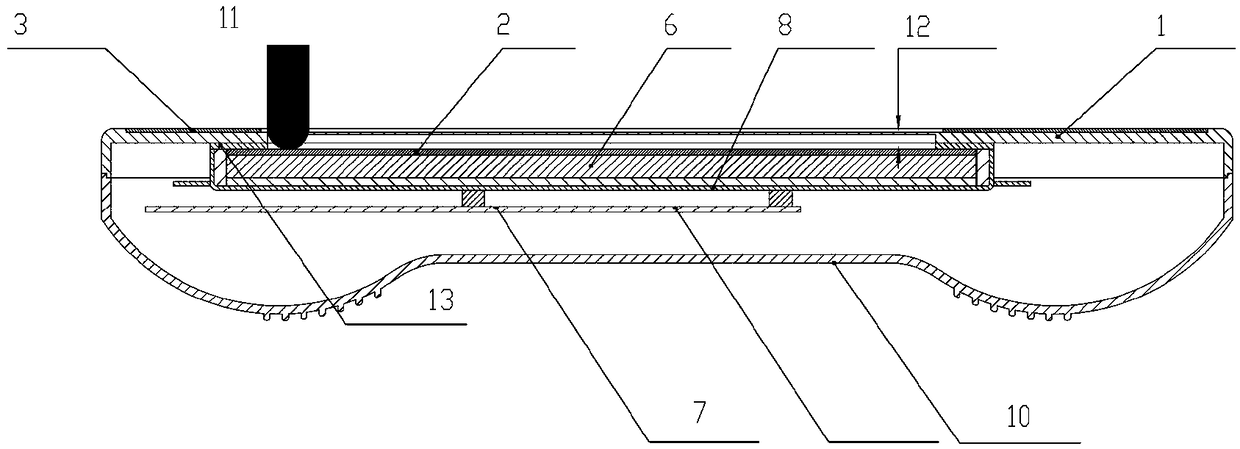

[0054] See figure 1 , discloses an external touch screen assembly structure, including a front case 1, a touch screen 2 and a membrane keyboard 3, the upper surface of the front case 1 is provided with a first groove 4 and a second groove 5, the front case 1 The upper surface, the first groove 4 and the second groove 5 form a two-level ladder structure; the outer side of the touch screen 2 is arranged in the second groove 4; the membrane keyboard 3 includes an outer side 3-1 and an inner side 3-2; the outer side of the membrane keyboard The outer side 3 - 1 is arranged in the first groove 4 , and the inner side 3 - 2 of the membrane keyboard is arranged on the touch screen 2 in the second groove 5 .

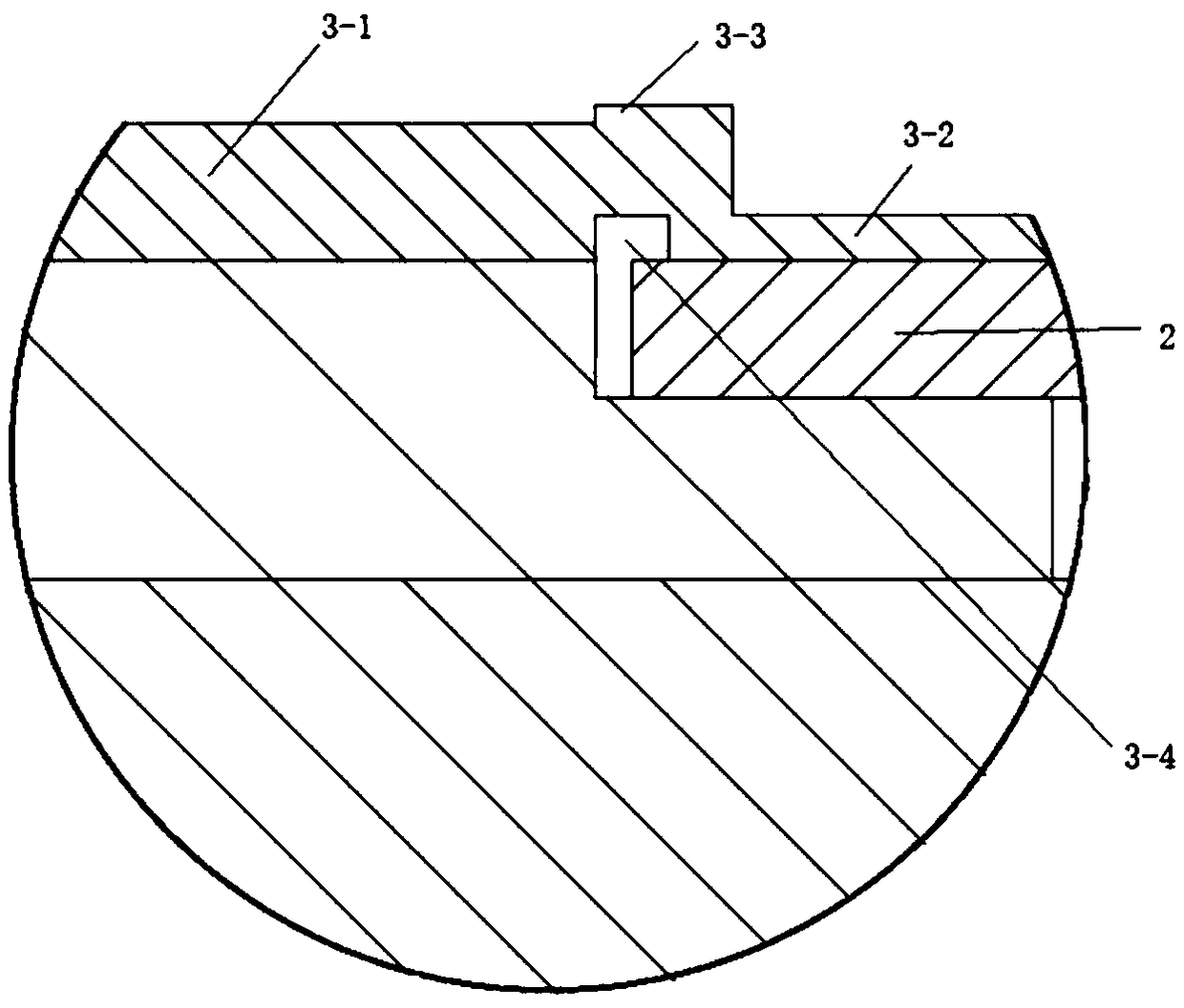

[0055] Please refer to figure 2 , a protrusion 3-3 is provided between the outer side 3-1 of the membrane keyboard and the inner side 3-2 of the membrane keyboard, a cavity 3-4 is provided at the bottom of the protrusion, and the cavity 3-4 is arranged in the first groove 4 an...

Embodiment 2

[0064] This embodiment also discloses another external touch screen assembly structure (refer to figure 1 ), including a front case 1, a touch screen 2 and a membrane keyboard 3, the upper surface of the front case 1 is provided with a first groove 4 and a second groove 5, the upper surface of the front case 1, the first groove 4 and The second groove 5 forms a two-level stepped structure; the outer side of the touch screen 2 is set in the second groove 5 ; the outer side of the membrane keyboard 3 is set in the first groove 4 .

[0065] Compared with the first embodiment, the membrane keyboard in the external touch screen assembly structure has no inner side, only an outer side (relative to Embodiment 1), and the membrane keyboard 3 is only arranged in the first groove 4.

[0066] The touch screen 2 is pasted on the upper surface of the second groove 5 by industrial adhesive; the outer side 3-1 of the membrane keyboard is pasted on the upper surface of the first groove 4 by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com