3D printing system based on 4-PSS/PS parallel mechanism

A 3D printing and parallel technology, applied in the field of 3D printing systems, can solve the problems of poor fusion of printed objects, single shape of printed objects, single printing form, etc., to achieve easy control, improve practicability and economy, and expand applications. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

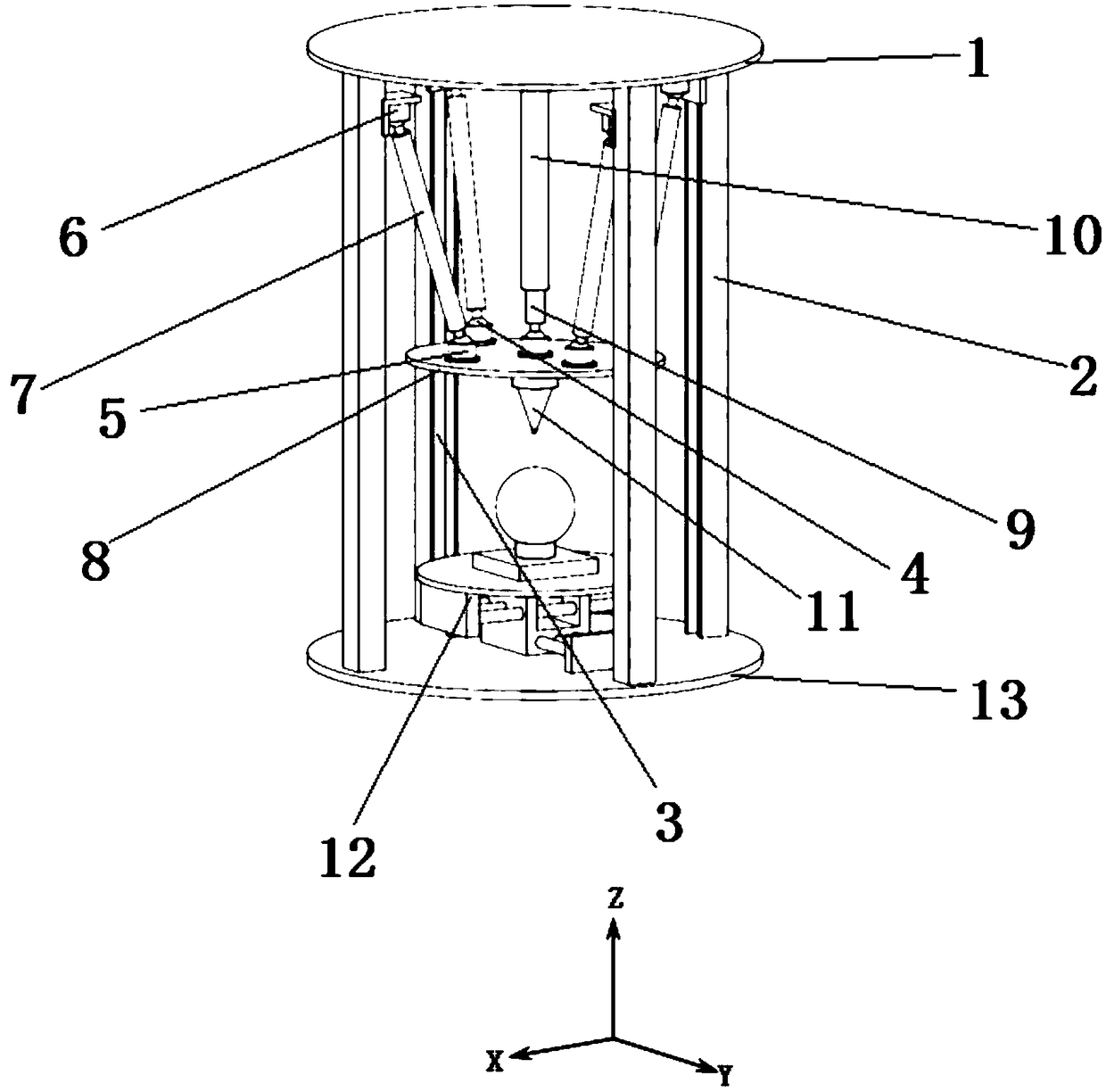

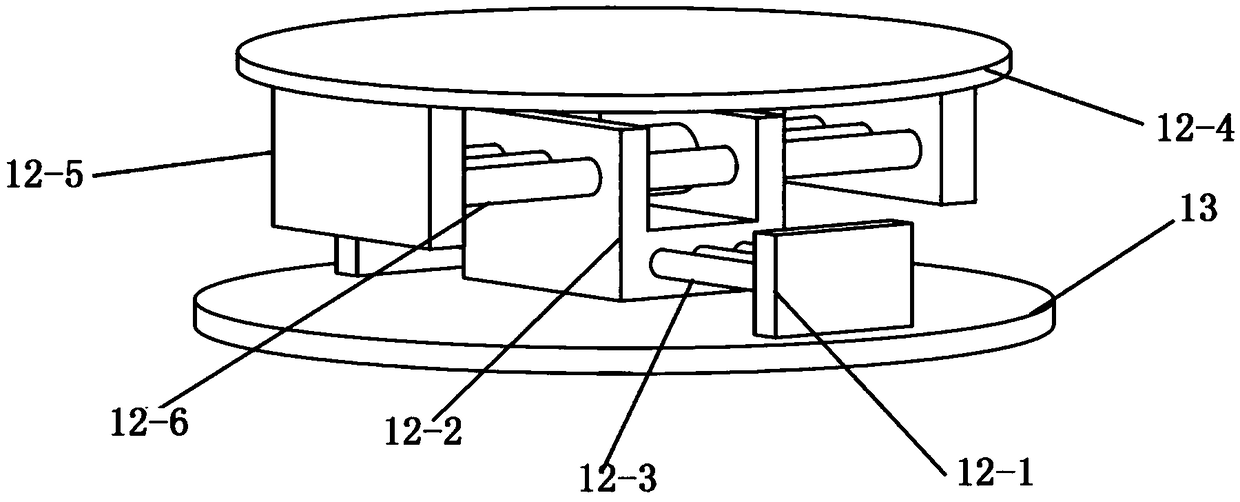

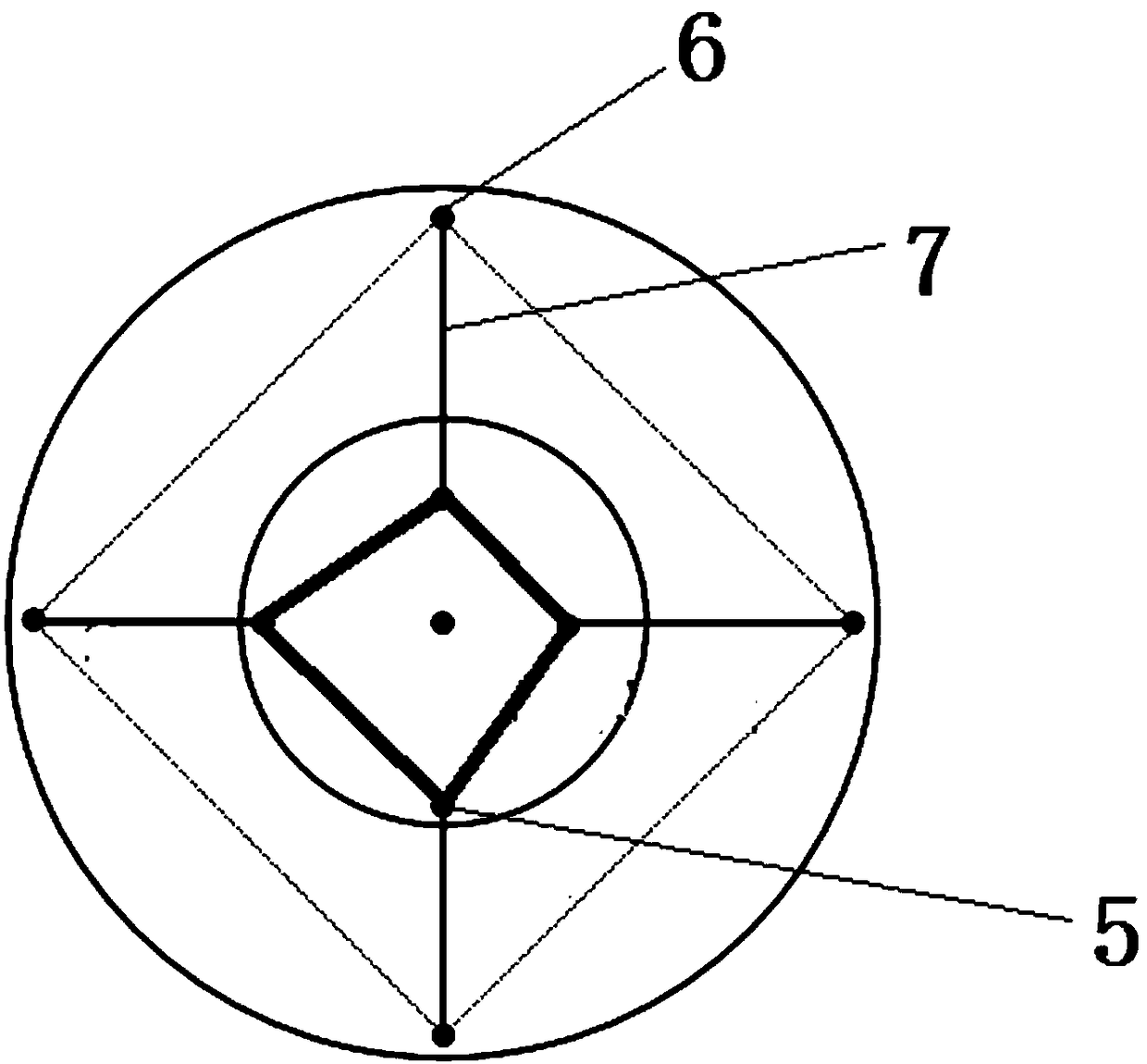

[0020] The present invention is based on the 3D printing system of 4-PSS / PS parallel mechanism, such as figure 1 As shown, it includes a top plate 1 and a bottom plate 13 that are parallel to each other. The top plate 1 and the bottom plate 12 are connected by guide rails 2. The guide rails 2 include four, and a ball screw a3 is arranged along the inner axis of each guide rail 2. There is a motor and reducer compatible with the ball screw a3, the ball screw a3 is sleeved with a slider 6, the motor drives the ball screw a3 to rotate after being decelerated by the reducer, the slider 6 is movably connected with a branch chain 7 On the upper platform 8, the slider 6 drives the branch chain 7 to move up and down along the guide rail 2 on the ball screw a3, and the upper platform 8 is also movably connected with the restraint branch chain 9, and t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap