Film scratching machine

A technology of scribing and racking, which is applied in the directions of packaging, binding material removal, cutting and unsealing, etc. It can solve the problems of difficult to remove the protective film, difficult to tear off the protective film, easy to scratch the protective film paint, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

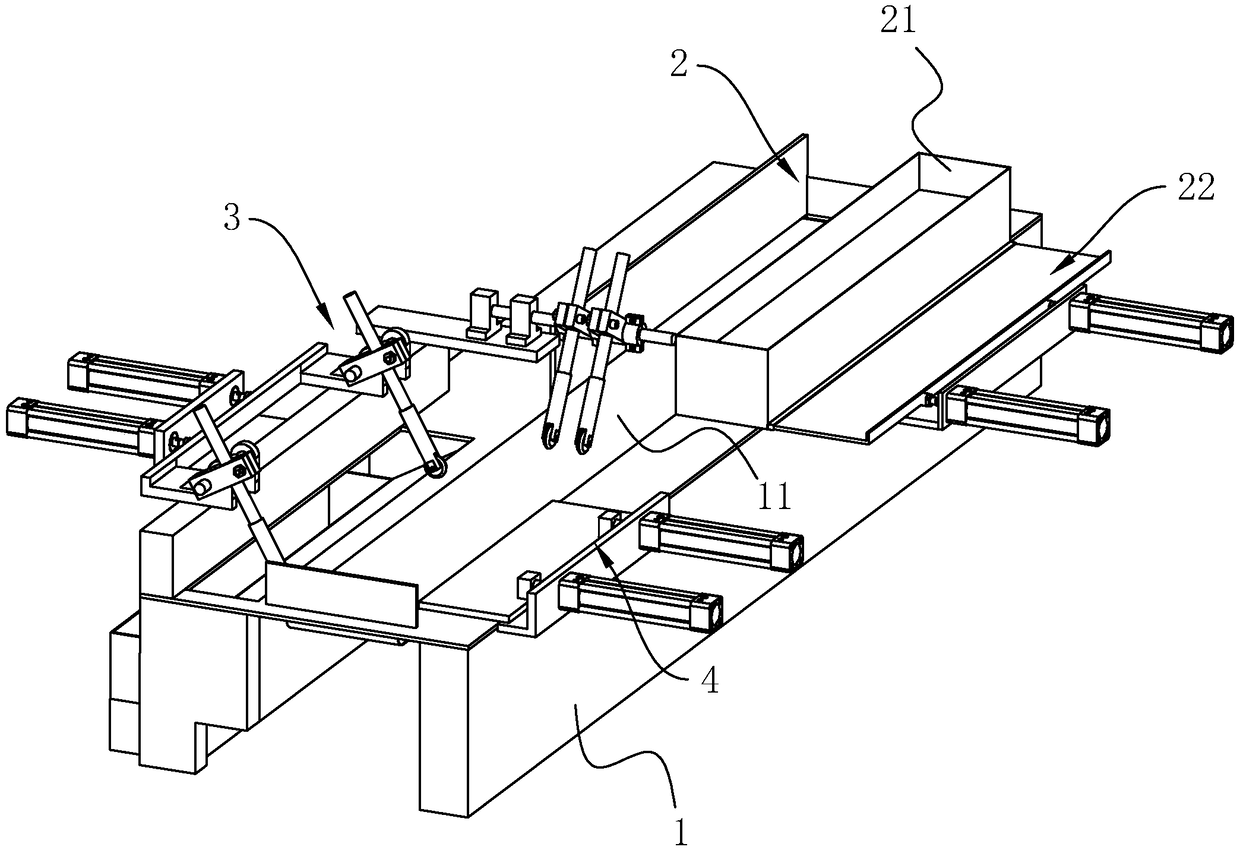

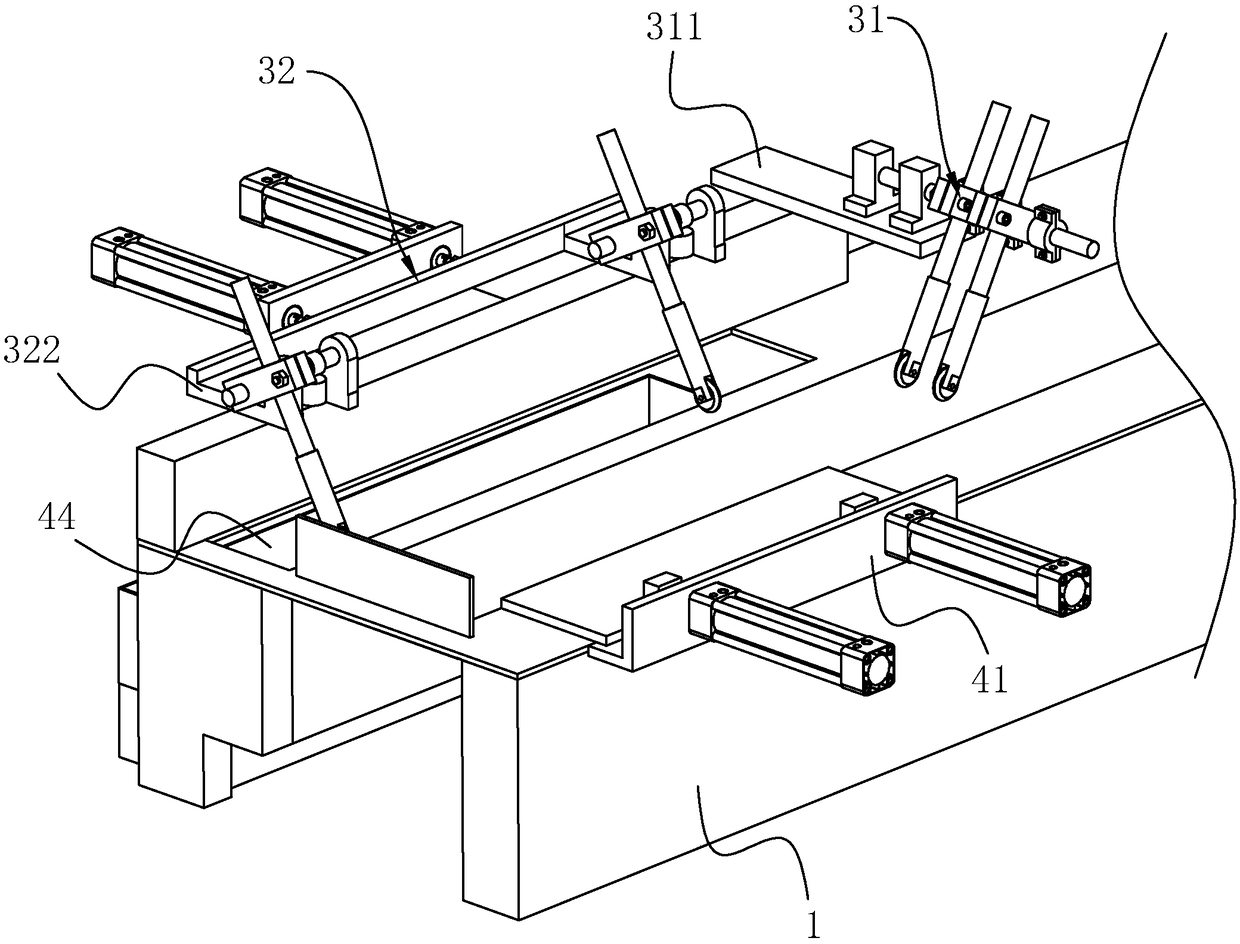

[0038] Embodiment: a kind of film cutting machine, see figure 1, including a frame 1 , an automatic feeding mechanism 2 arranged on one side of the frame 1 , and a film marking mechanism 3 and an automatic unloading mechanism 4 arranged on the other side of the frame 1 . A conveyor belt 11 is connected to the top of the frame 1, and a power source for driving its movement is connected to the conveyor belt 11. The shell plate enters the conveyor belt 11 from the automatic feeding mechanism 2, and the conveyor belt 11 moves to the automatic unloading mechanism 4, and the film marking mechanism 3 draws marks on the top of the shell plate on the conveyor belt 11, so as to facilitate tearing off the protective film from the mark Down.

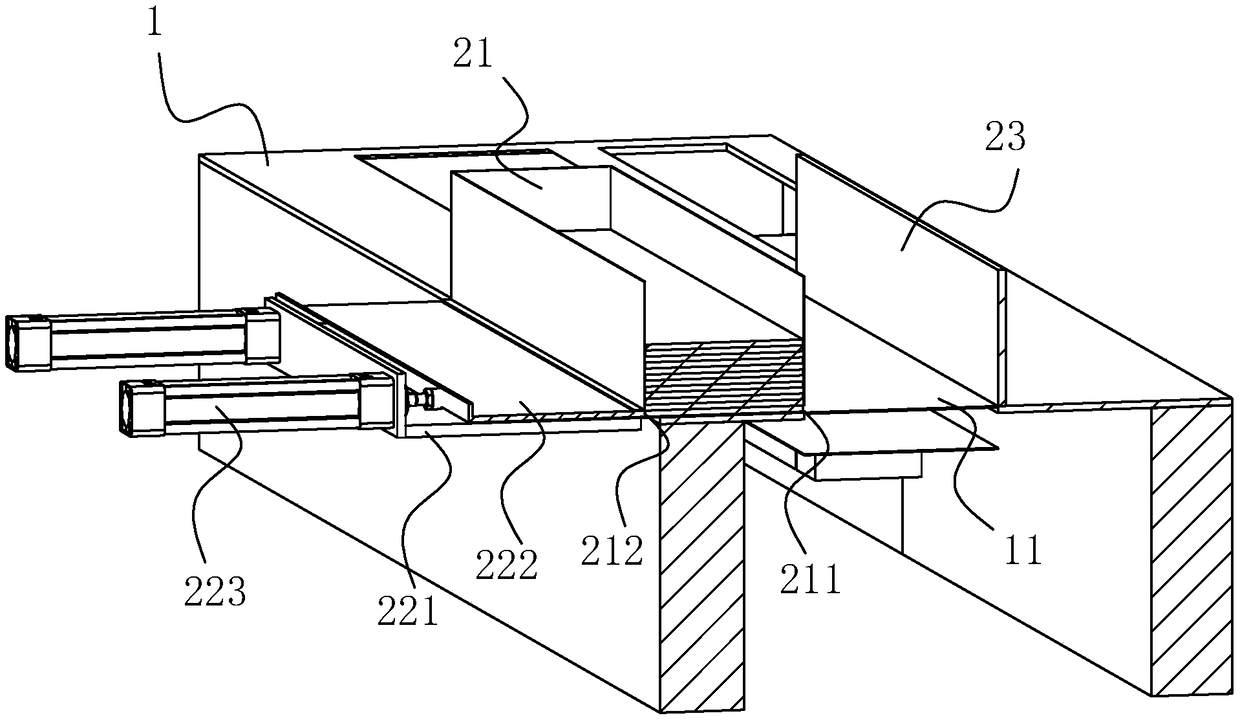

[0039] see figure 1 and figure 2 , the automatic feeding mechanism 2 includes a feeding box 21 fixed on one side of the conveyor belt 11 and a pushing assembly 22 fixed on the side of the loading box 21 away from the conveyor belt 11 . The uppe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap