Carrying and conveying device of battery cell

A technology for conveying devices and batteries, which is applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc. It can solve the problems of unsure position of batteries and slipping of batteries, and achieve long-distance battery transportation and stable lifting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further described in conjunction with the following examples.

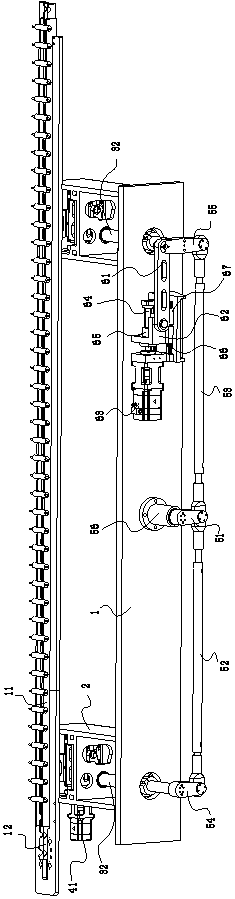

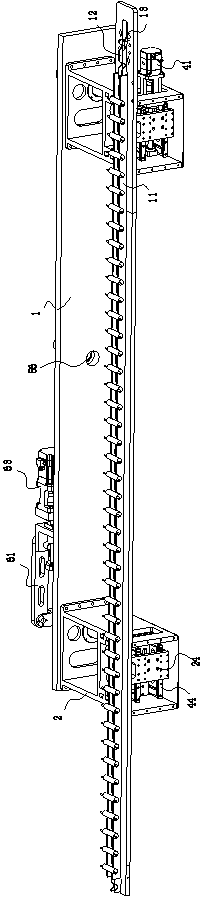

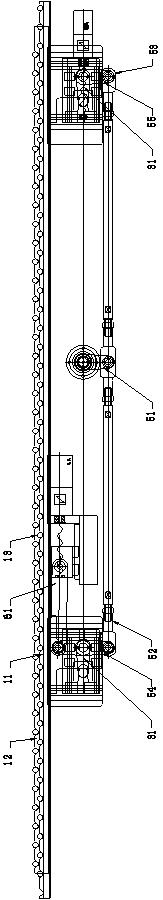

[0026] Depend on Figure 1 to Figure 6 It can be seen that a battery cell transporting device described in this embodiment includes a frame 1, a fixed support seat 11 fixed on the frame 1, and a movable support seat 12 that is movable on the fixed support seat 11; the fixed support Both the seat 11 and the movable support seat 12 are provided with a cell slot 13 for placing the cell;

[0027] Both sides of the frame 1 are provided with a horizontal movement mechanism for driving the movable support seat 12 to move horizontally and a vertical movement mechanism for driving the movable support seat 12 to move vertically; the frame 1 is provided with a vertical driving member and A linkage mechanism for synchronizing the vertical movement mechanisms on both sides of the frame 1 ; the vertical driving member is connected to the vertical movement mechanisms on both sides of the frame 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com