Plunger material conveying machine

A technology of feeder and plunger, which is applied in the field of feeder, can solve the problems of low conveying efficiency, small material conveying volume, and inability to convey materials separately, so as to achieve the effect of increasing conveying quantity and improving conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

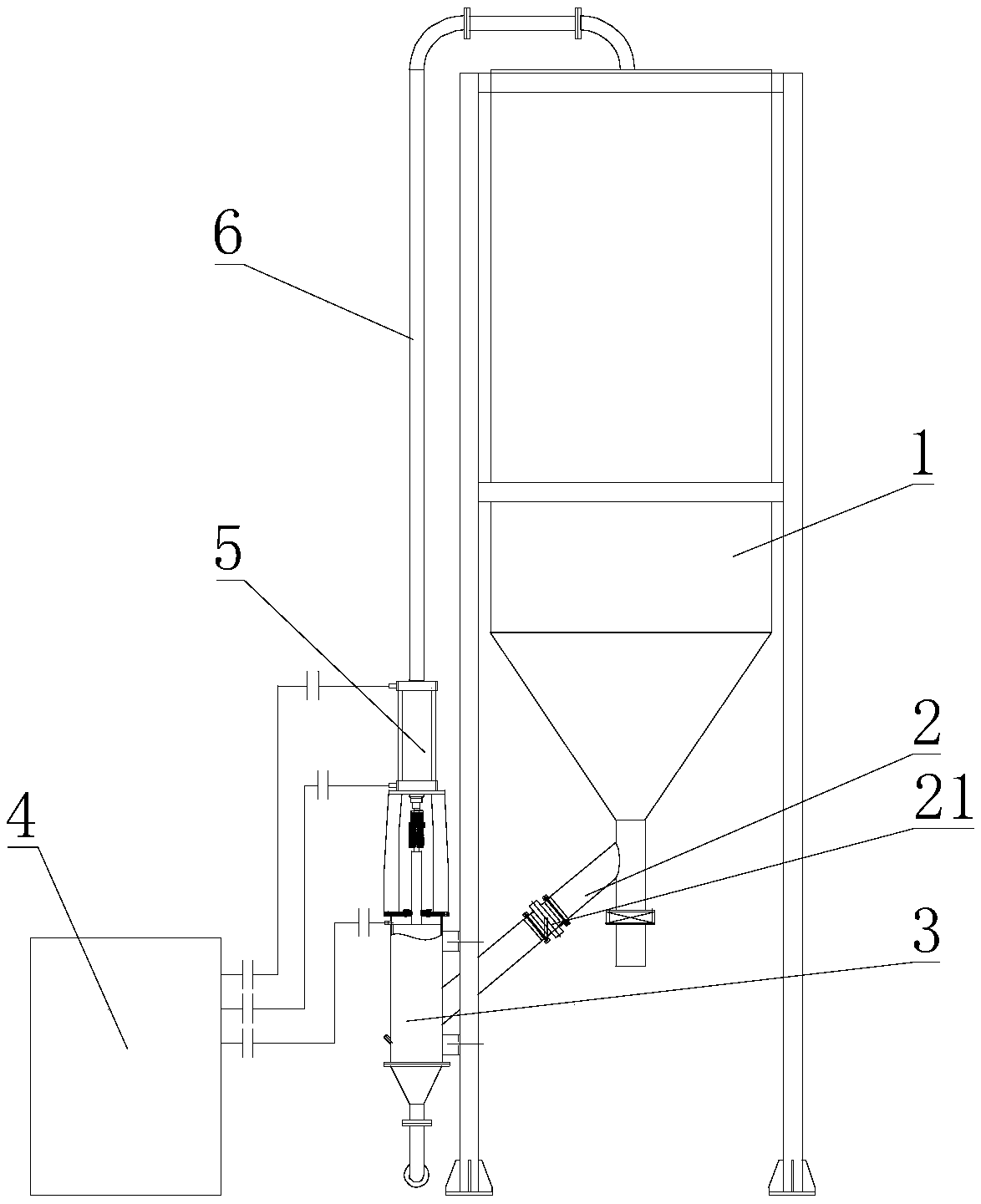

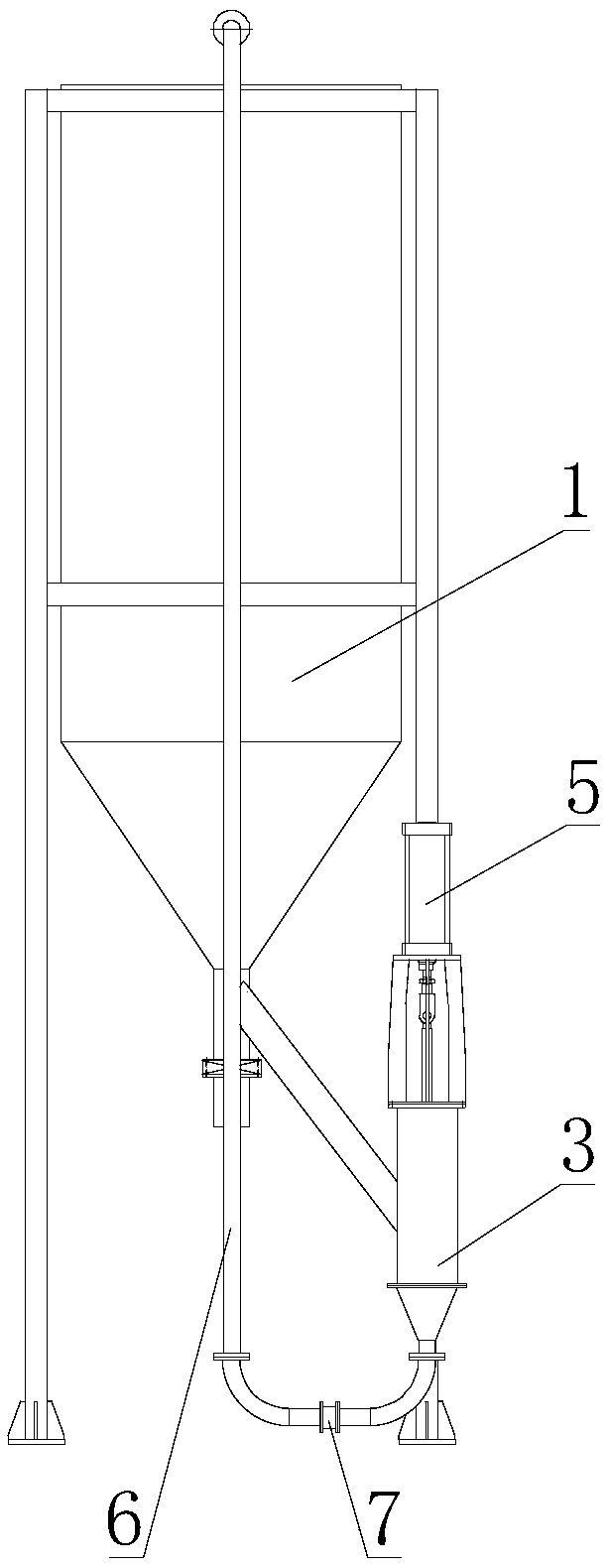

[0015] As shown in the figure, the plunger conveyor includes a silo 1, the silo 1 is connected with a discharge pipe 2, the discharge pipe 2 is communicated with the inner cavity of the plunger pump 3, and the plunger The inner cavity of the pump 3 is communicated with the compressed air device 4, and the compressed air device 4 can be fed with compressed air to seal the piston of the plunger pump 3 and its cylinder, and the piston of the plunger pump 3 is connected to the cylinder 5 by transmission, The output end of the plunger pump 3 is communicated with a feeding pipe 6 , and a check valve 7 is installed at the input end of the feeding pipe 6 . The material conveying pipe 6 can be communicated with the silo 1 to achieve the technical effect of material backflow, and can be communicated with other material silos for conveying materials to achieve the technical effect of conveying materials.

[0016] In order to further switch on and off the output of the material in the sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com