Big equipment single hook hoisting positioning device and method

A lifting device and positioning device technology, applied in transportation and packaging, load hanging components and other directions, can solve the problems of many professional and technical personnel, can not be in place at one time, large errors, etc., achieve strong operability, reduce investment, method easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

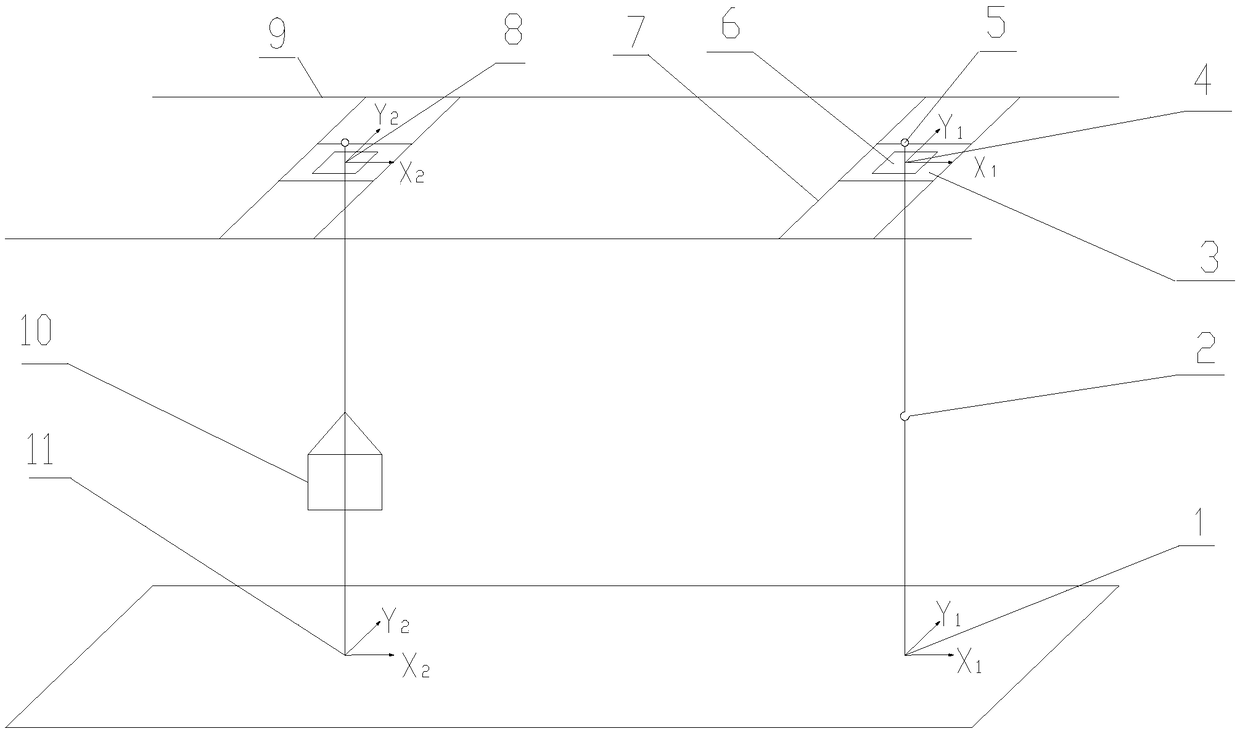

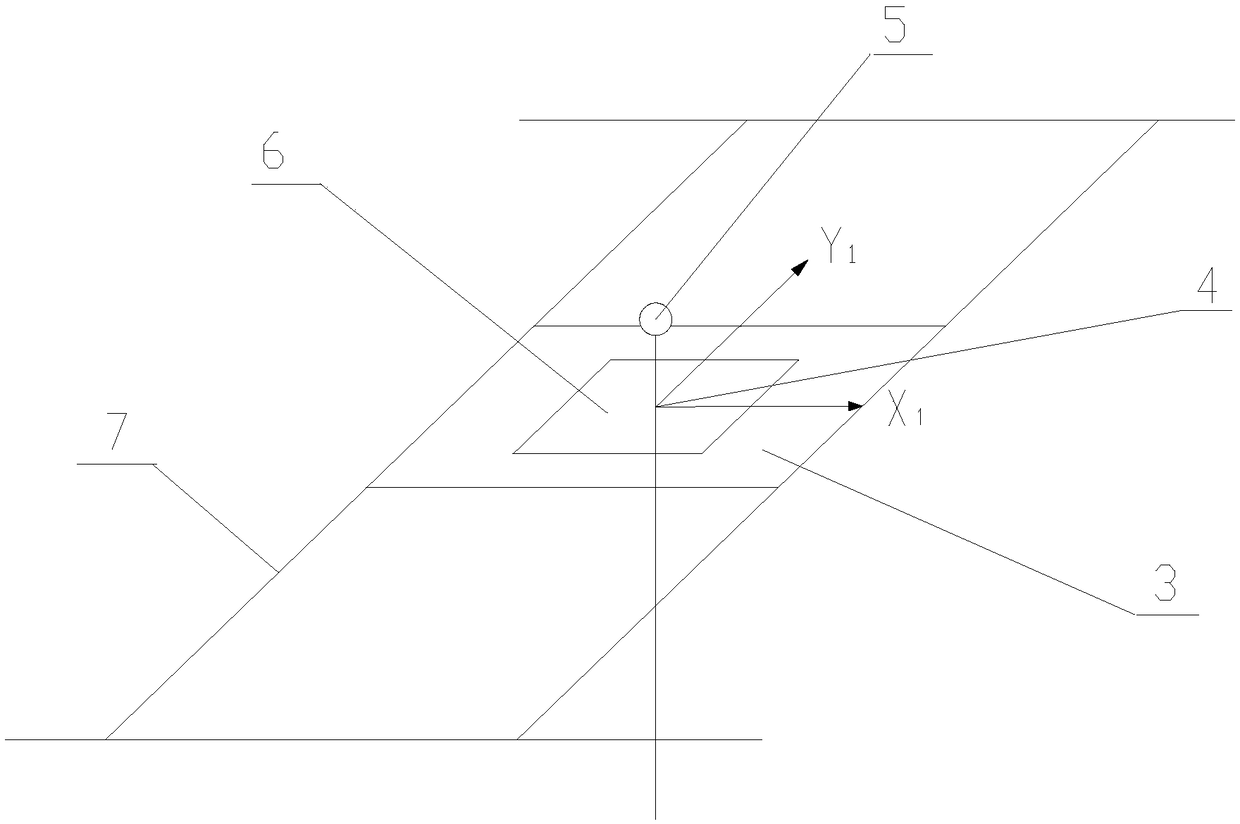

[0019] see figure 1 , figure 2 , the present invention comprises hoisting device, and hoisting device comprises the bridge machine trolley 3 on the bridge machine 7 that is installed on the bridge machine track 9 and bridge machine 7, bridge machine hook 2 is installed below the bridge machine trolley 3. Its key technology is to install a measurement system on the lifting device. The measurement system is measured by a total station to ensure accuracy. The prism 5 of the station instrument and the suspension hook 2 of the bridge crane are located below the central position of the adjustable support 6 . The adjustable bracket 6 can be adjusted horizontally and centrally to adjust the horizontally and centrally of the prism 5 to ensure that the center of the adjustable bracket 6 coincides with the projection center of the hook.

[0020] The crane hook 2 and the prism 5 are located on the same straight line.

[0021] A single-hook hoisting and positioning method for large-sca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com