Wafer carrier detection method and inspection tool

A carrier and wafer technology, which is applied in the field of chip manufacturing auxiliary tools, can solve the problems of easy deviation in wafer carrier detection, achieve the effect of not easy to detect errors, improve detection efficiency, and detect and judge quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

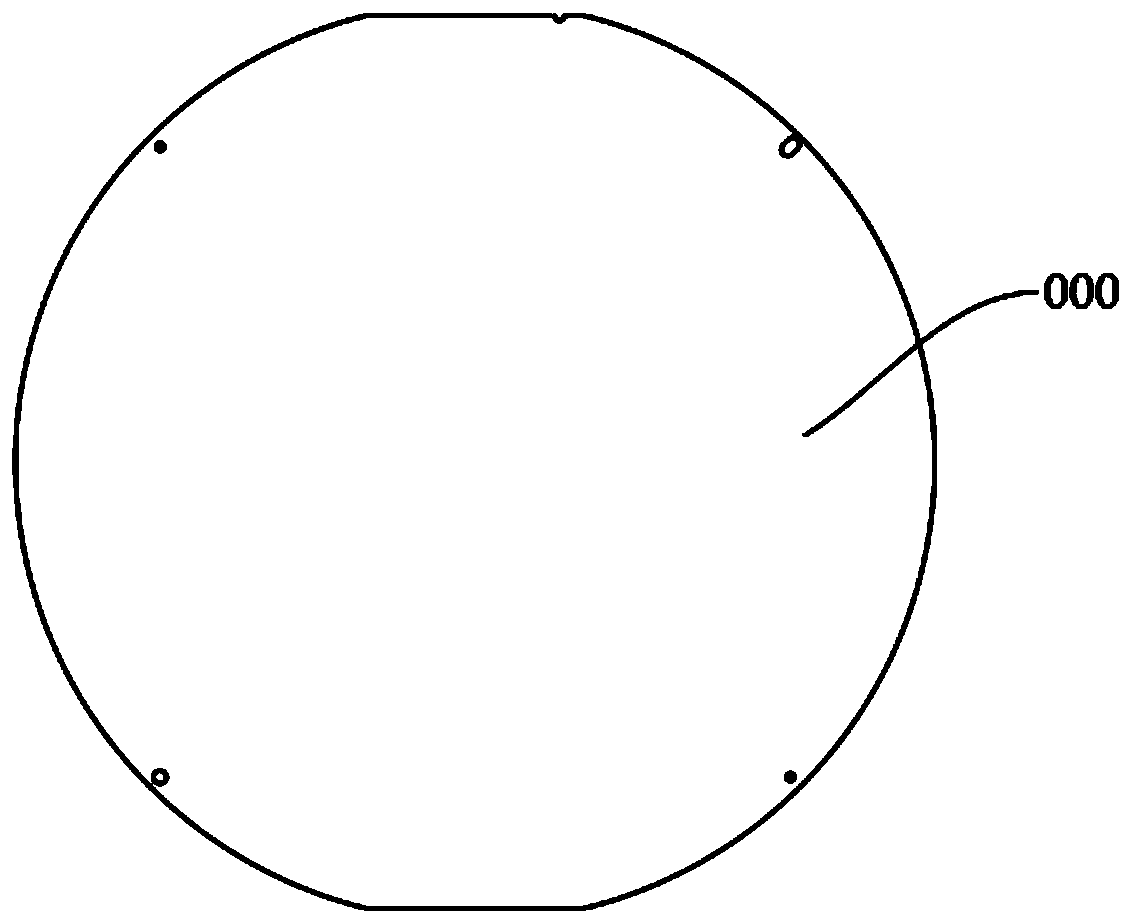

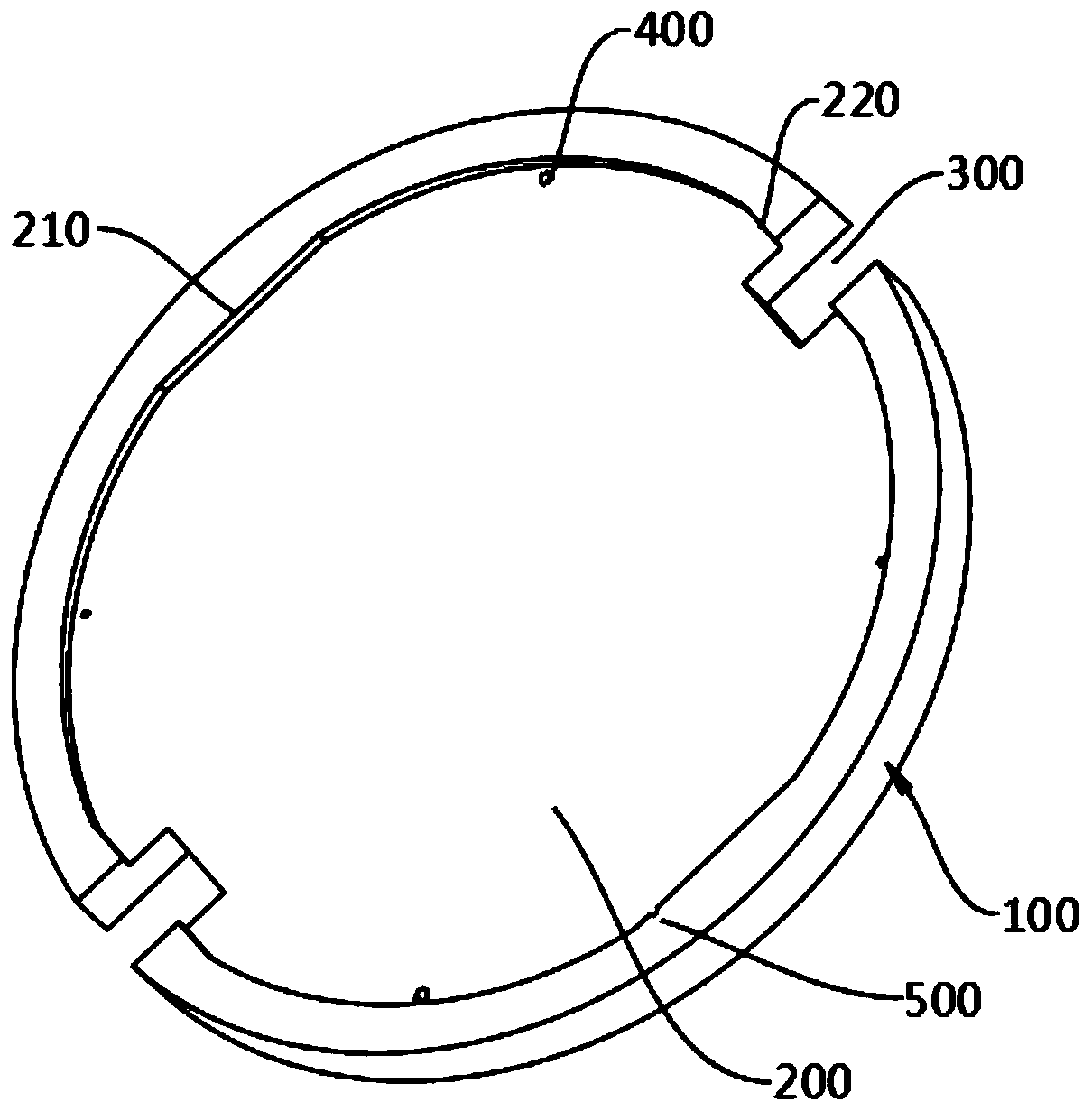

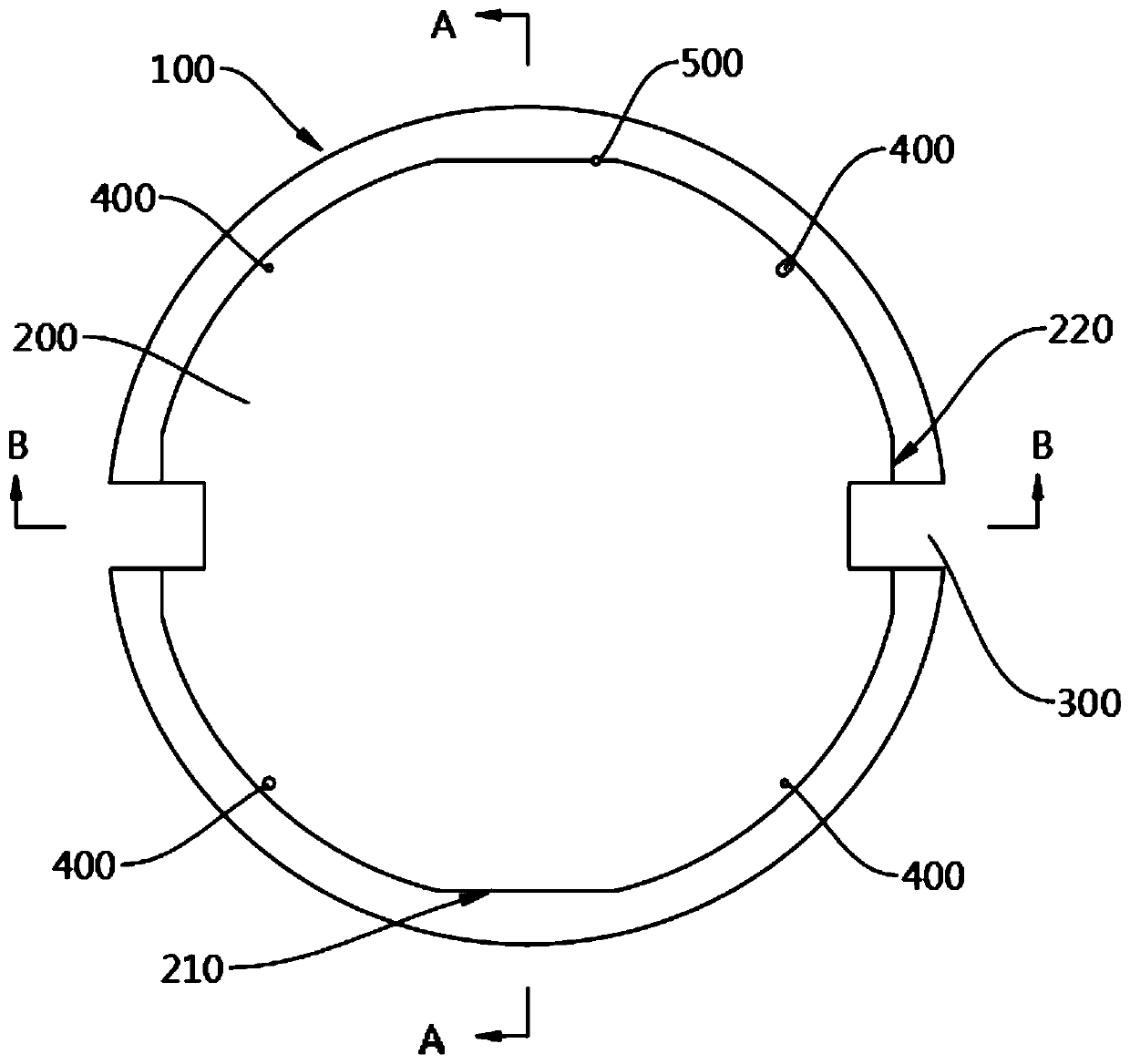

[0038] attached figure 1 It is a schematic diagram of the structure of wafer carrier 000; attached figure 2 is a schematic diagram of the three-dimensional structure of the inspection tool; Figure 3-6 It is a schematic diagram of the structure of the inspection tool under different viewing angles; Figure 7 , 8 It is a structural schematic diagram of the mounting device 600 under different viewing angles.

[0039] Please refer to attached figure 1 , the wafer carrier is roughly circular, and the edge is partially linear. There are four through holes on the wafer carrier 000, and an open half-hole is formed on the linear portion of the edge.

[0040] A wafer carrier 000 inspection tool is used for detecting the shape and size of the external structure of the wafer carrier, and for detecting the position and size of through holes and half holes on the wafer carrier.

[0041] Please refer to attached figure 2 As shown, the tester includes a tester body 100, and the cente...

Embodiment 2

[0056] In order to further improve the detection efficiency, on the basis of Embodiment 1, a mounting tool 600 for assembling the plug gauge 900 is also provided to simultaneously detect multiple through holes and open half holes on the same wafer carrier 000. The tool 600 can help to speed up the efficiency of batch testing.

[0057] Please refer to attached Figure 7 with 8 As shown, the above-mentioned mounting tool 600 is provided with a plurality of mounting holes 700 for assembling plug gauges 900 , and the plug gauges 900 can be inserted and fixed in the mounting holes 700 .

[0058] An elastic ring is arranged in the installation hole 700, and the middle part of the elastic ring has a channel for clamping the plug gauge 900. The elastic ring can adapt to the plug gauge 900 of different specifications, and it is convenient to replace the plug gauge 900 of different specifications as required.

[0059] Please refer to attached Figure 7 with 8 As shown, in order to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com