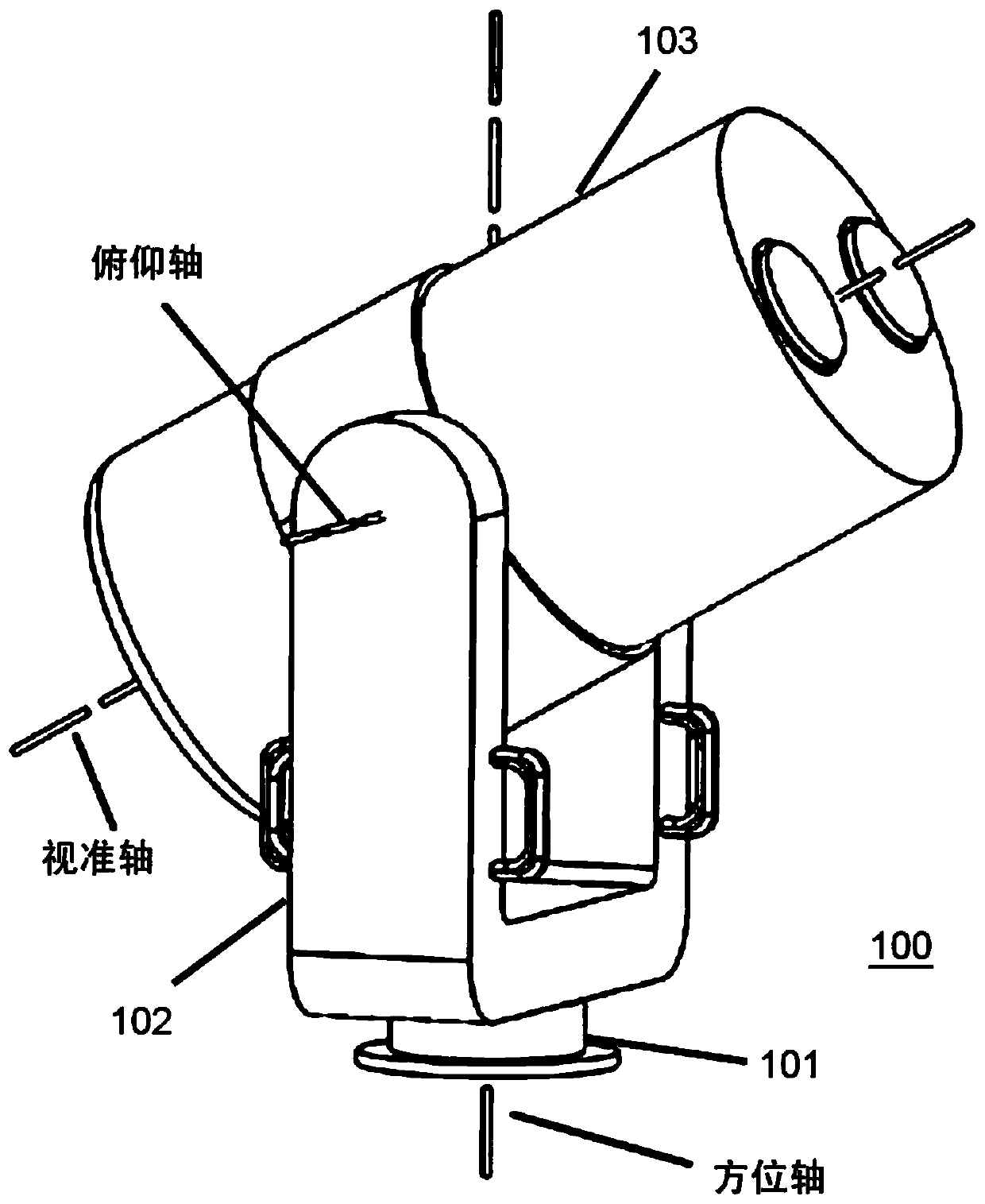

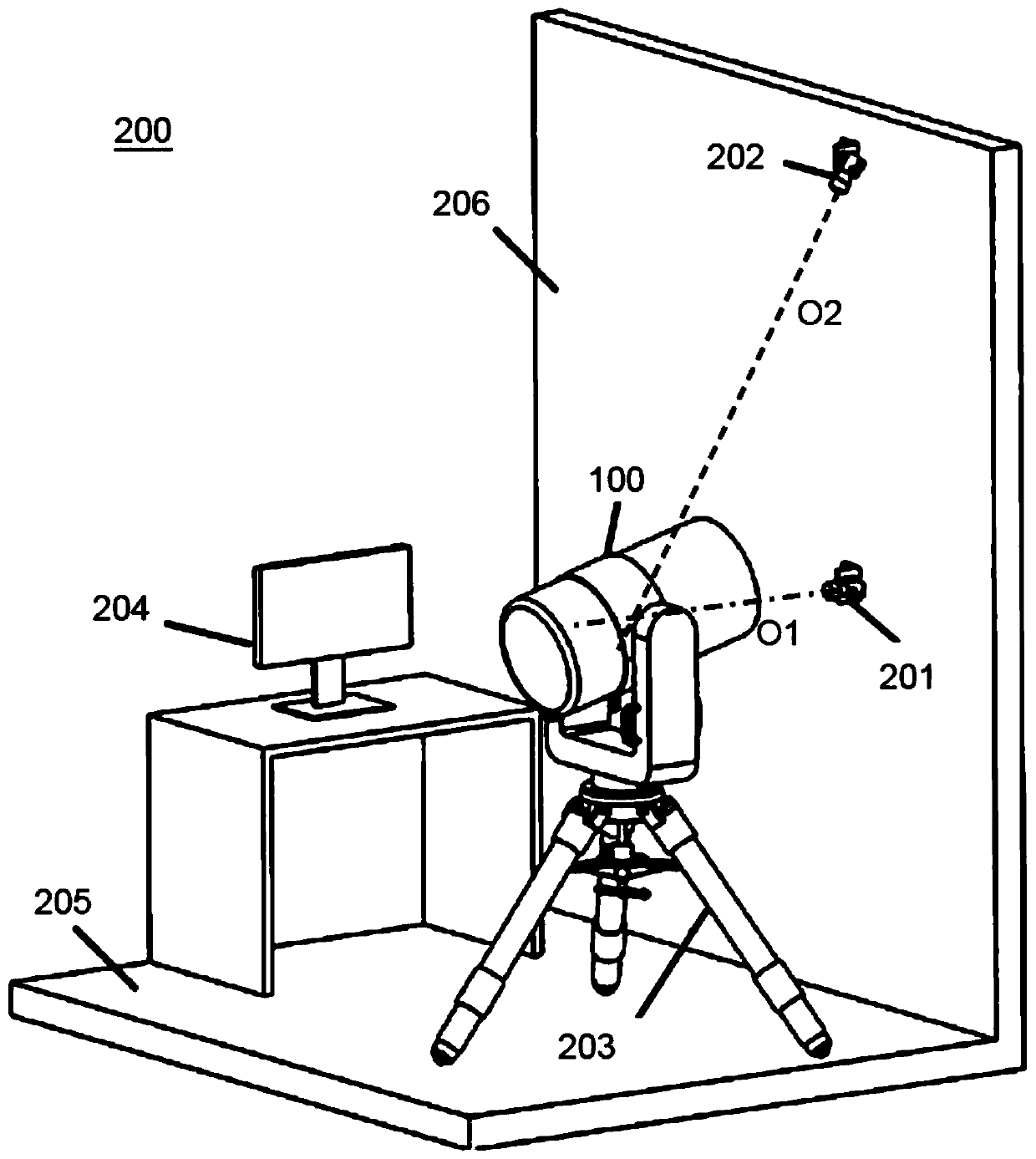

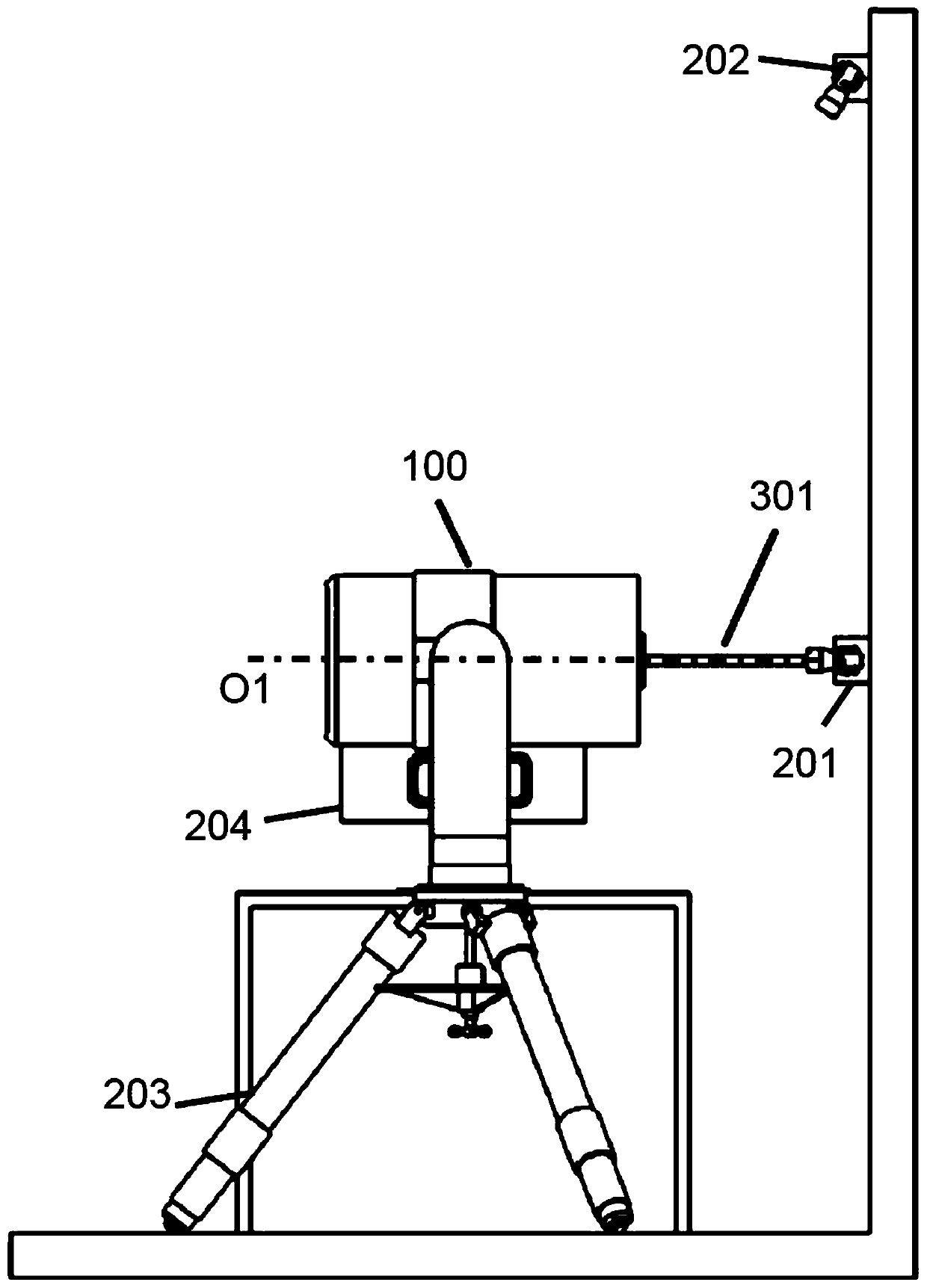

Shafting perpendicularity detection device and method for horizontal photoelectric tracking system

A photoelectric tracking system and detection device technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of error, inconvenient adjustment, complicated operation process, etc., and achieve the effect of not easy to detect error, simple structure, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

[0024] In the following embodiments, when referring to numbers and the like (including numbers, values, amounts, ranges, etc.) of elements, except for the cases where it is particularly clearly stated and the case where it is clearly limited to a specific number in principle, it does not mean Limited to the specific number, may be above or below the specific number.

[0025] In addition, in the following embodiments, the structural elements (including process elements, etc.) are not necessarily essential except for the case where it is particularly clearly stated and the case where it is clearly understood as essential in principle, and the description may also be included. Elements not expressly mentioned in , need not be stated.

[0026] Similarly, in the following embodiments, when referring to the shape, positional relationship, etc....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elevation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com