Three-dimensional surface shape measurement device and method for mirror object based on infrared stripes

A measuring device and three-dimensional surface shape technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of visible light interference and affecting measurement results, and achieve the effect of ingenious design, improved collection efficiency, and high collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

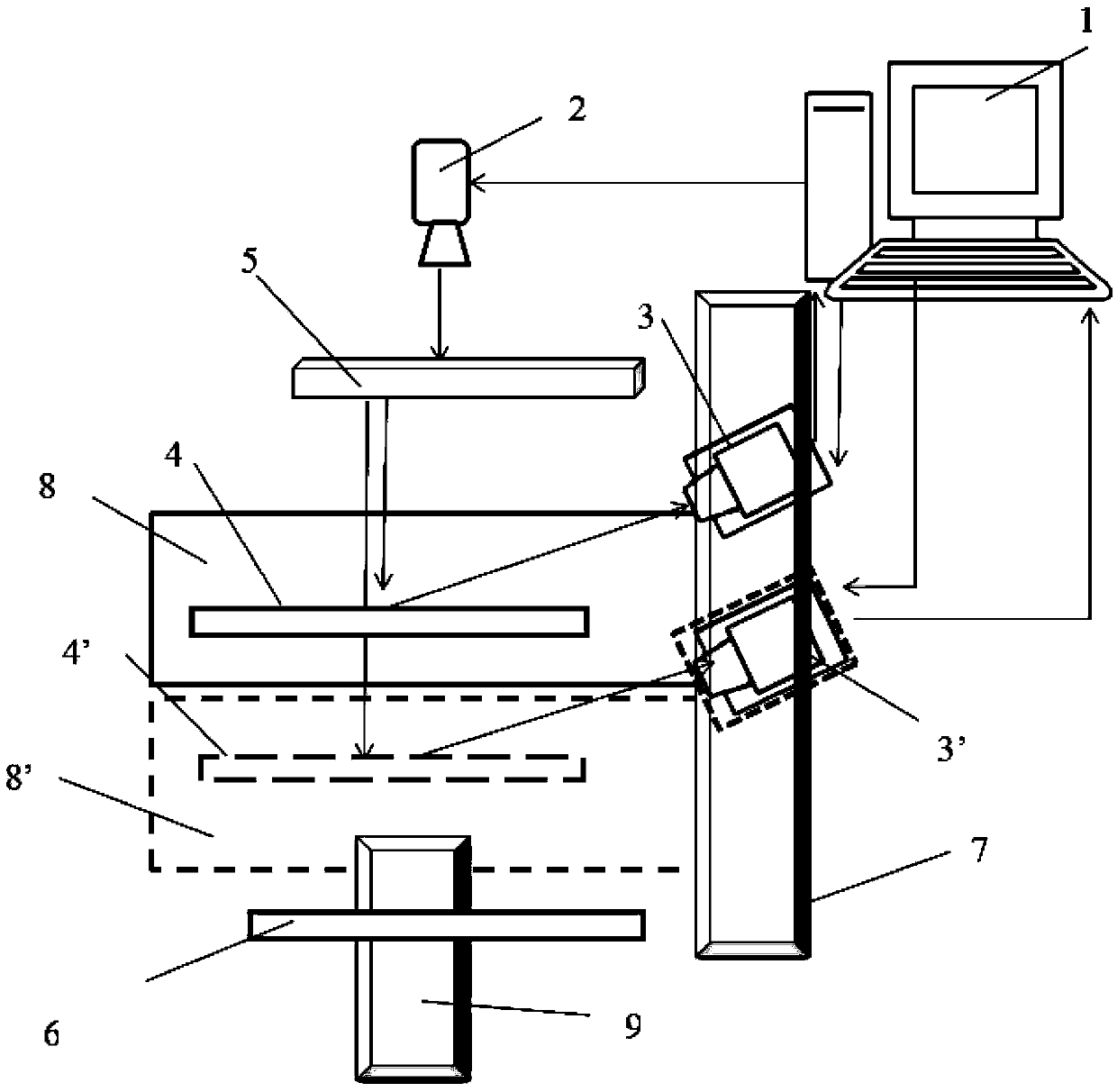

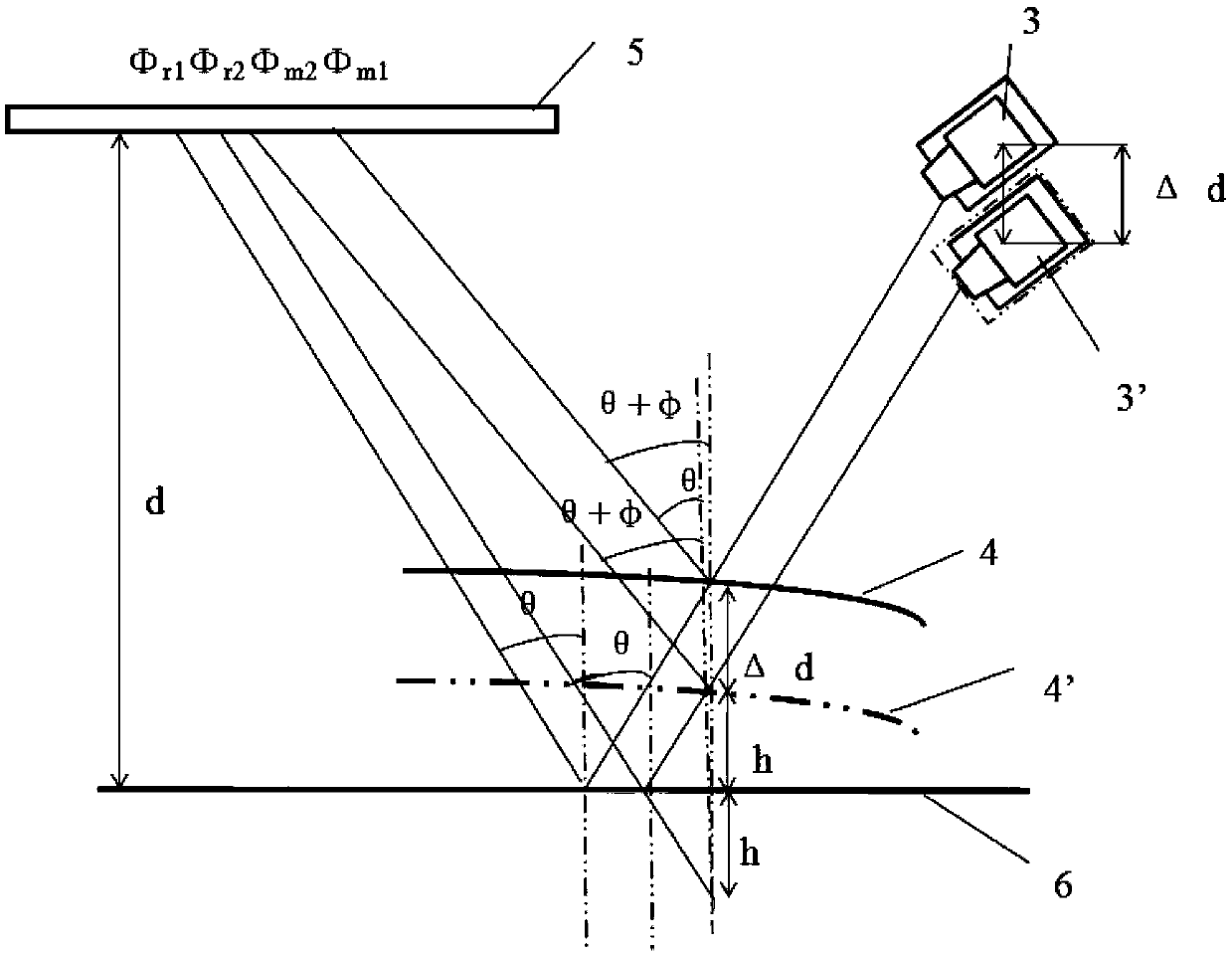

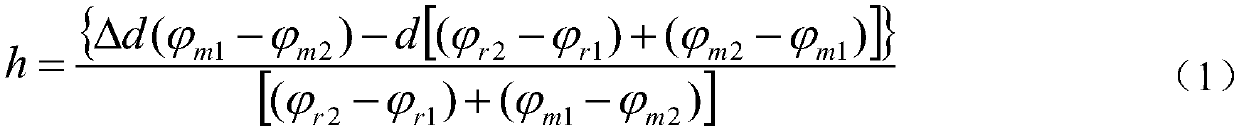

[0036] The invention provides a device for measuring the three-dimensional surface shape of a specular object based on infrared stripes (referred to as the device, see figure 1 ), characterized in that the device includes a computer 1, an infrared projector 2, a CCD infrared camera 3, a mirror object to be measured 4, a frosted glass 5, a reflector 6 with a ring mark on the surface, a first high-precision horizontal moving guide rail 7, Fixed plate 8 and the second high-precision horizontal moving guide rail 9; the computer 1 is connected with infrared projector 2, CCD infrared camera 3, the first high-precision horizontal moving guide rail 7 and the second high-precision horizontal moving guide rail 9 respectively, and the computer 1 It i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com