Helmet penetration resistance testing device and method

A testing device and helmet technology, which is applied in the measurement device, using repetitive force/pulsation force to test the strength and strength characteristics of materials, etc., can solve the problems of poor reliability of test data and the inability to accurately locate the lifting height of the impact hammer, and achieve the test process. The effect of convenience, improving test accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

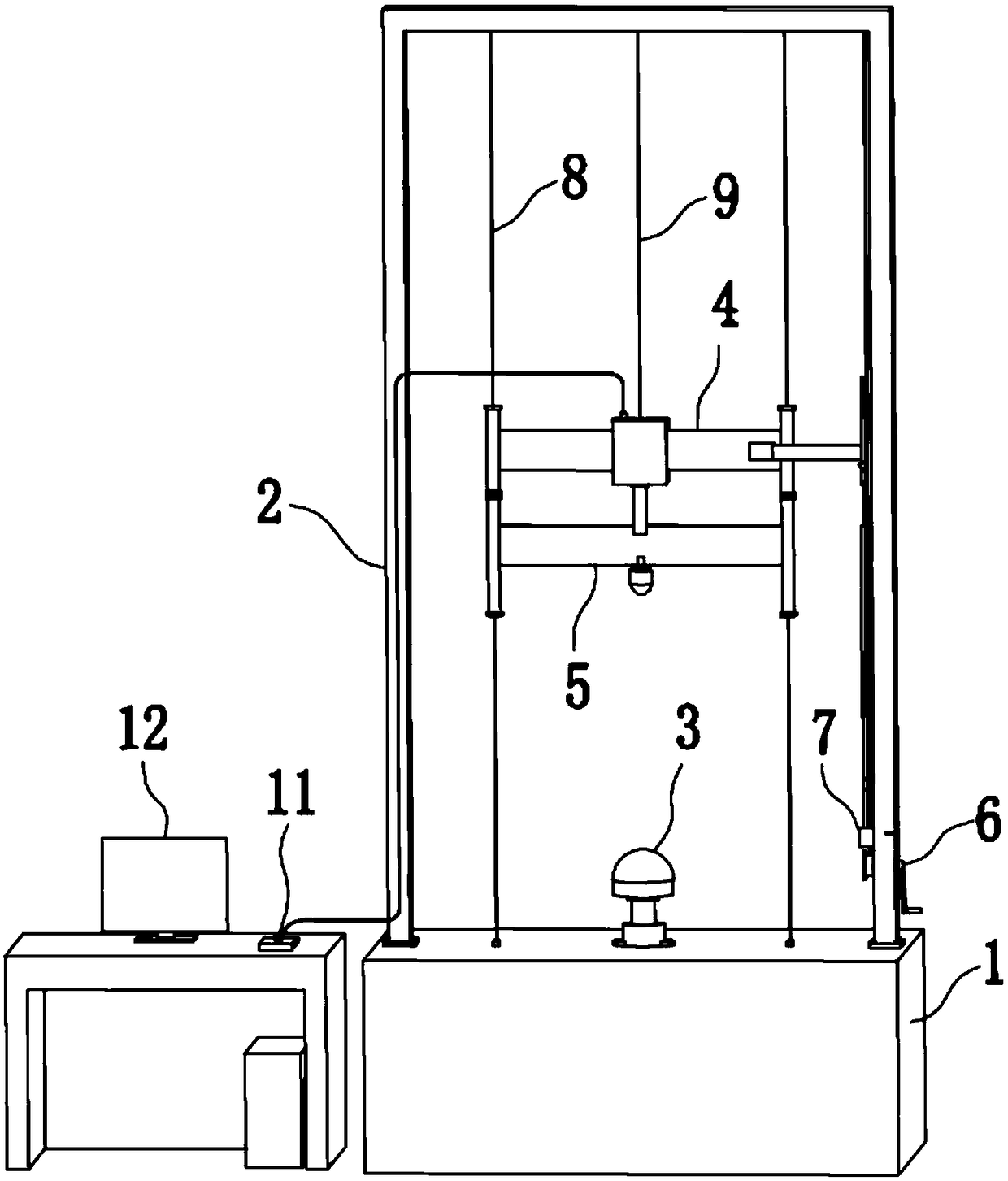

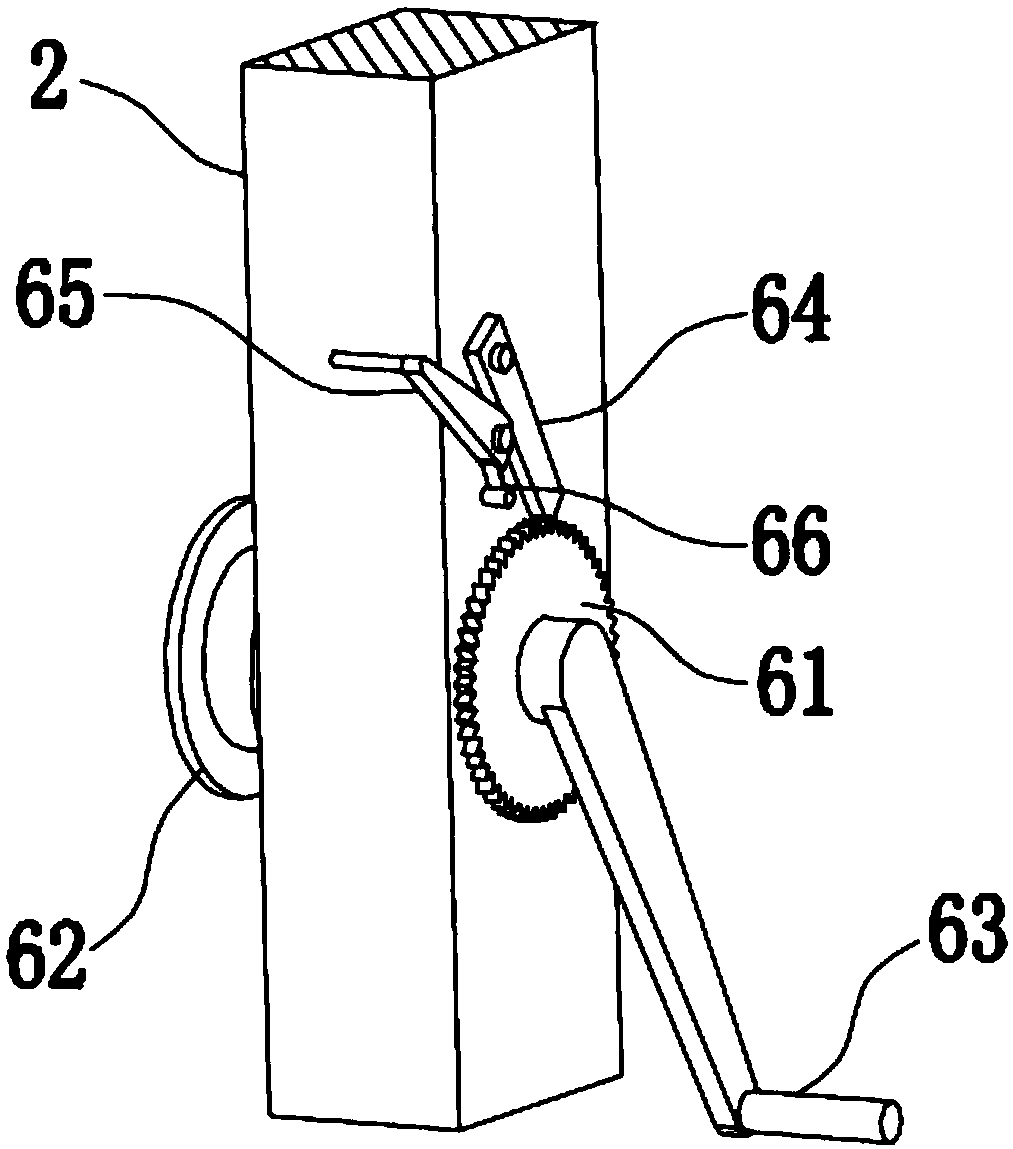

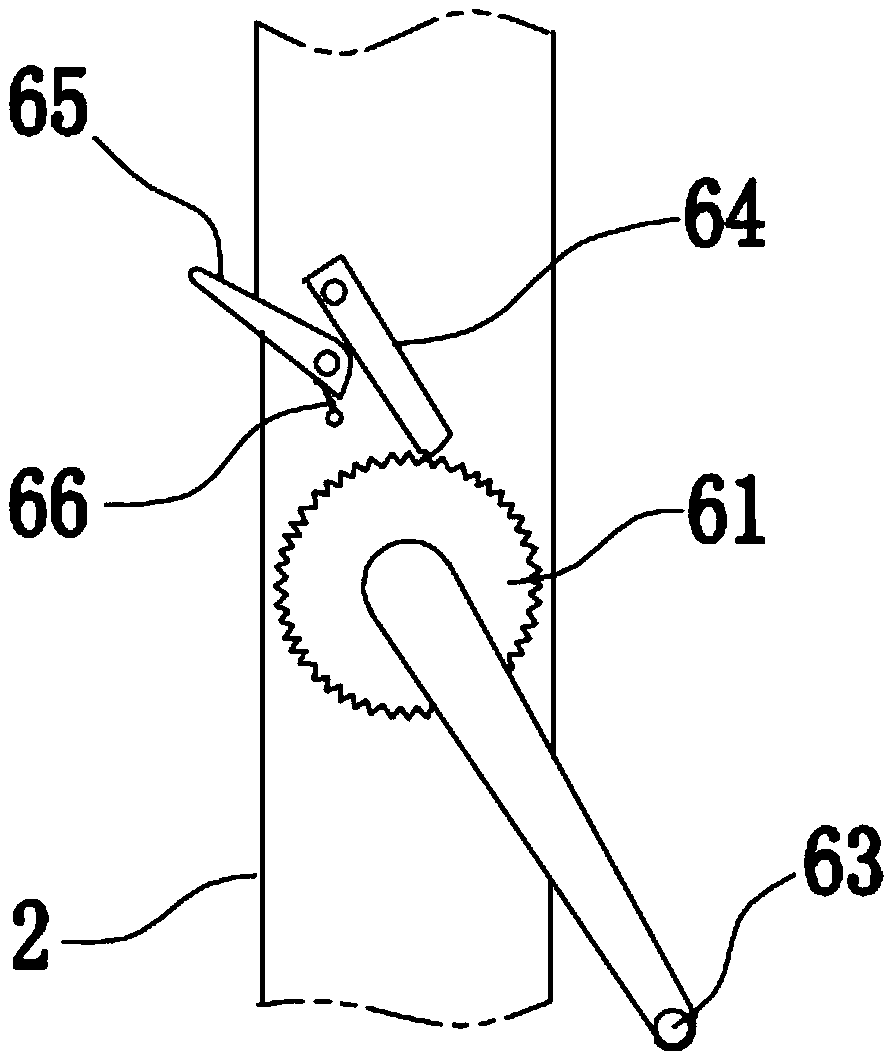

[0058] A helmet penetration resistance test device, such as figure 1 , 5 , 6, including anvil base 1, support 2, steel wire guide rail 8, release mechanism 4, falling mechanism 5, lifting wire 9, lifting mechanism 6 and headform device 3; said support 2 is a door frame shape, including two A vertical column and a beam at the top, the bracket 2 is vertically fixed on the anvil base 1, the upper end of the steel wire guide rail 8 is fixedly connected with the bracket 2, and the lower end is connected with the anvil base 1 fixedly connected, the steel wire guide 8 is two steel wires vertically parallel and tensioned; Slide up and down; one end of the lifting steel wire 9 is fixedly connected to the release mechanism 4, the other end is connected to the lifting mechanism 6, and the middle part is detoured on the roller 10 arranged at the top of the support 2. By controlling the lifting mechanism 6 can lift the release mechanism 4 and the drop mechanism 5, such as Figure 4 As s...

Embodiment 2

[0075] A kind of helmet penetration resistance testing device of the present embodiment, the basic structure is the same as that of embodiment 1, the differences and improvements are as follows: Figure 5 , 6 As shown, the upper adjustment mechanism includes a connecting rod I73, a sleeve I74 and a fastening knob I75; the sleeve I74 is sleeved on the connecting rod I73, and the fastening knob I75 is screwed on the sleeve I74, and through the sleeve I74 against the connecting rod I73; the lower end of the connecting rod I73 is fixedly connected with the tape head of the tape measure 72; one end of the connecting plate 70 is connected with the release mechanism 4 It is fixedly connected, and the other end is fixedly connected with the sleeve I74.

[0076] When adjusting, turn the fastening knob I75 to loosen the locking of the connecting rod I73, then move the connecting rod I73 up and down until the zero point of the scale on the tape measure 72 is at the same water height as ...

Embodiment 3

[0079] A kind of helmet penetration resistance testing device of the present embodiment, the basic structure is the same as that of embodiment 2, the differences and improvements are as follows: Figure 6 As shown, the lower adjustment mechanism includes a connecting rod II76, a sleeve II77, a fastening knob II78 and a reference plate 79; the connecting rod II76 is vertically fixed on the tape measure box 71, and the sleeve II77 is sleeved on on the connecting rod II76; the fastening knob II78 is screwed on the sleeve II77, and passes through the sleeve II77 to be pressed against the connecting rod II76; one end of the reference plate 79 is connected to the sleeve The tube II 77 is fixedly connected, and the other end extends to the front side of the tape of the measuring tape 72 . In this embodiment, the reference plate 79 is a transparent plastic plate or a glass plate, and the reference plate 79 is provided with a horizontal positioning line, which cooperates with the tape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com