Electric power testing socket

A technology of test seat and electric power, which is applied in the direction of the measuring device shell, etc., can solve the problems of short service life and poor structural strength, and achieve the effect of long service life, strong corrosion resistance and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

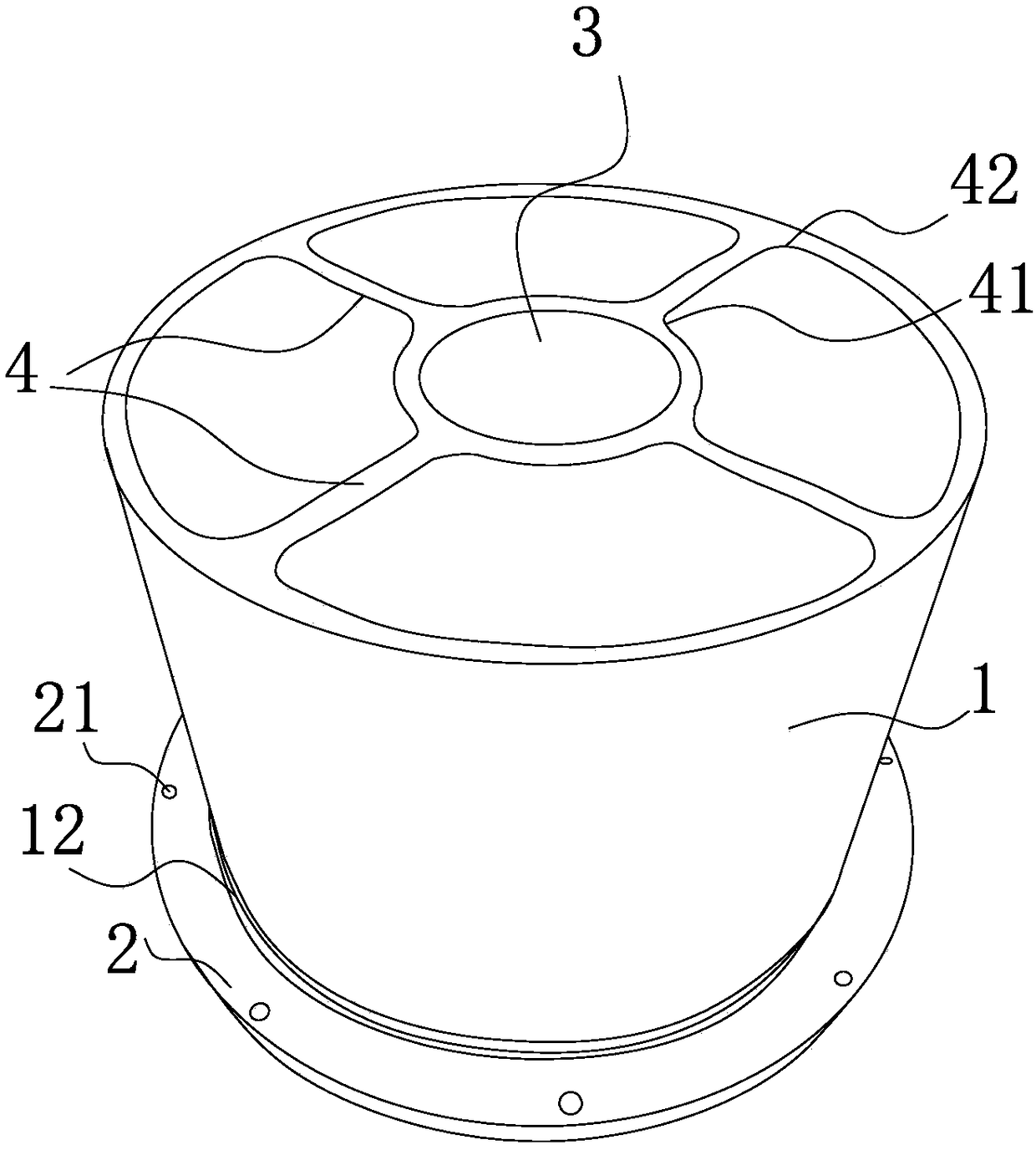

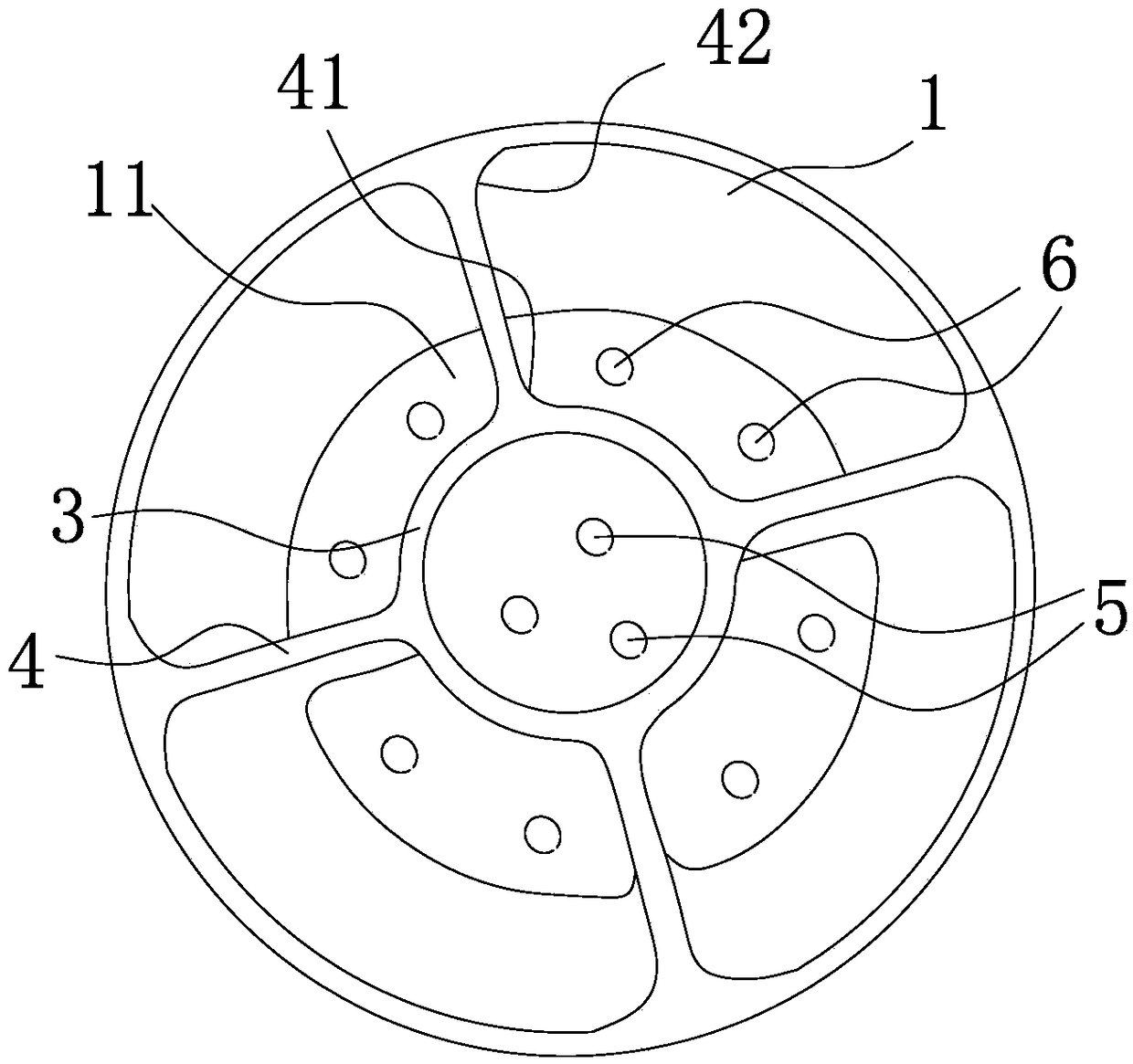

[0013] like figure 1 , 2 As shown, the electric test seat includes a cylindrical seat body 1 with one end open and one end closed and made of polytetrafluoroethylene. The seat body 1 is provided with a positioning ring 2 on the end far away from the opening, and the positioning ring 2 is connected to the seat body 1. One-piece structure, the positioning ring 2 is provided with fixing holes 21 evenly distributed along the circumferential direction, the middle part of the end plate 11 of the base body 1 is provided with an isolation tube 3, the isolation tube 3 is coaxially arranged with the base body 1 and the end The plate 11 is connected to the isolation tube 3 in an integrated structure, and at least two isolation plates 4 are evenly distributed along the circumferential direction between the isolation tube 3 and the base body 1, and the isolation plates 4 are connected to the end plate 11 and the base body 1 respectively. Integral structure, the axial length of the isolati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com