Adjustable sound head button

A sound head button and adjustable technology, applied to stringed instruments, instruments, etc., can solve the problems of time-consuming and laborious maintenance and fine adjustment, the piano cannot stop the sound, and the small contact area, so as to reduce training expenses, lower entry barriers, optimize The effect of craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

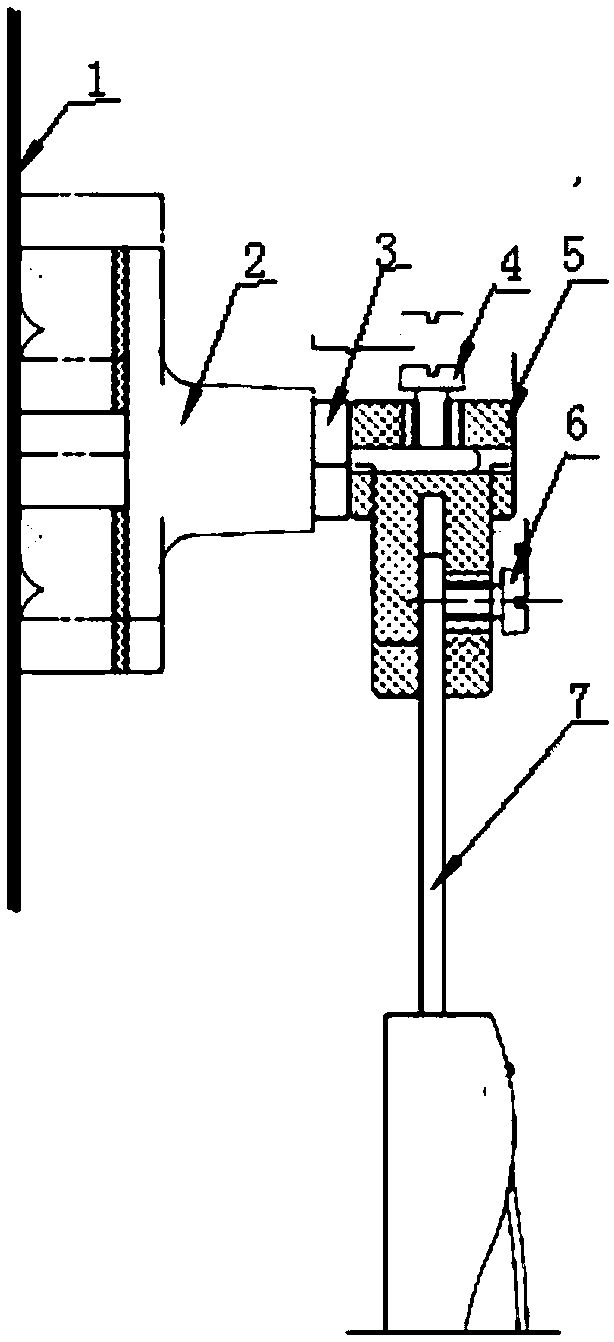

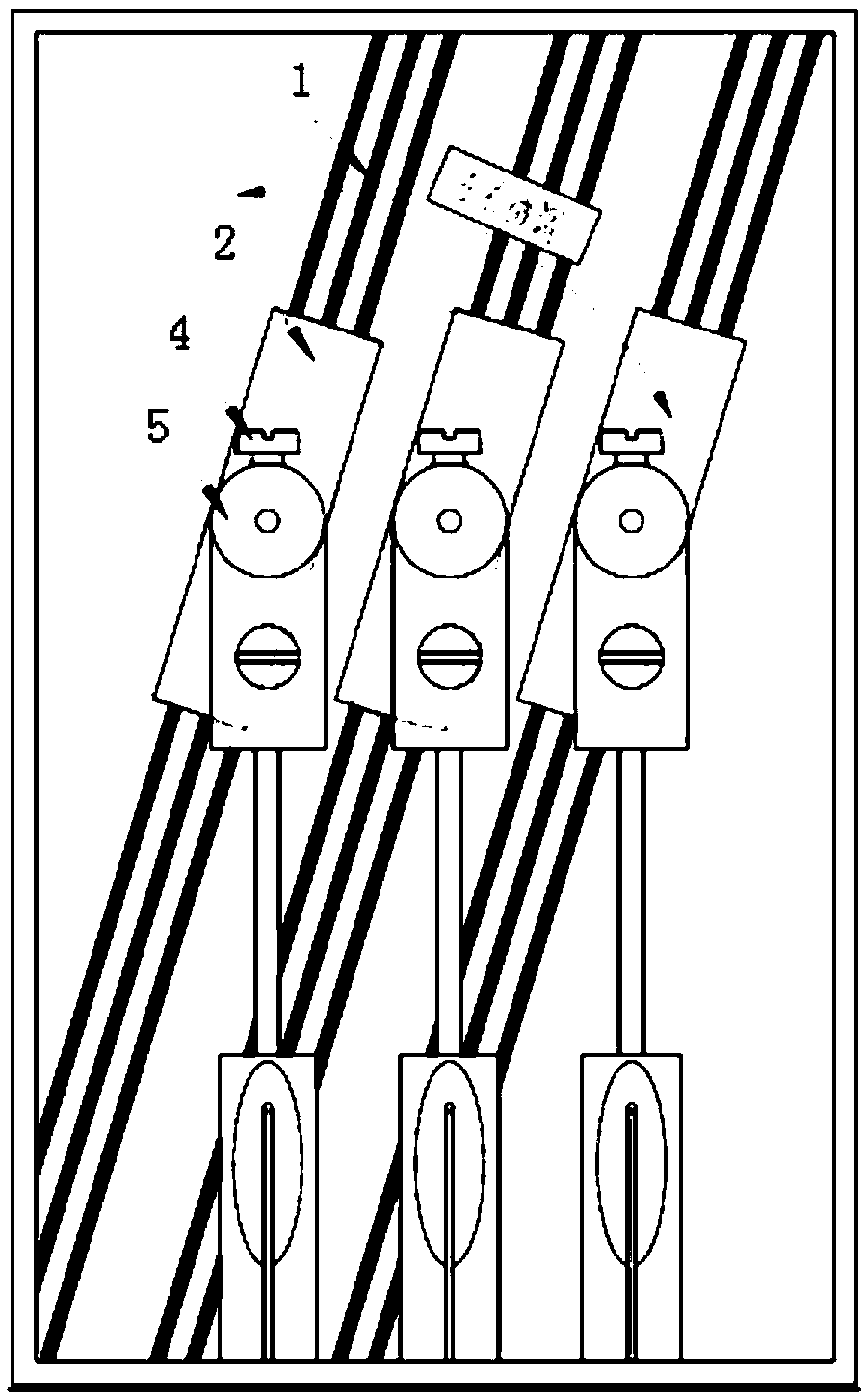

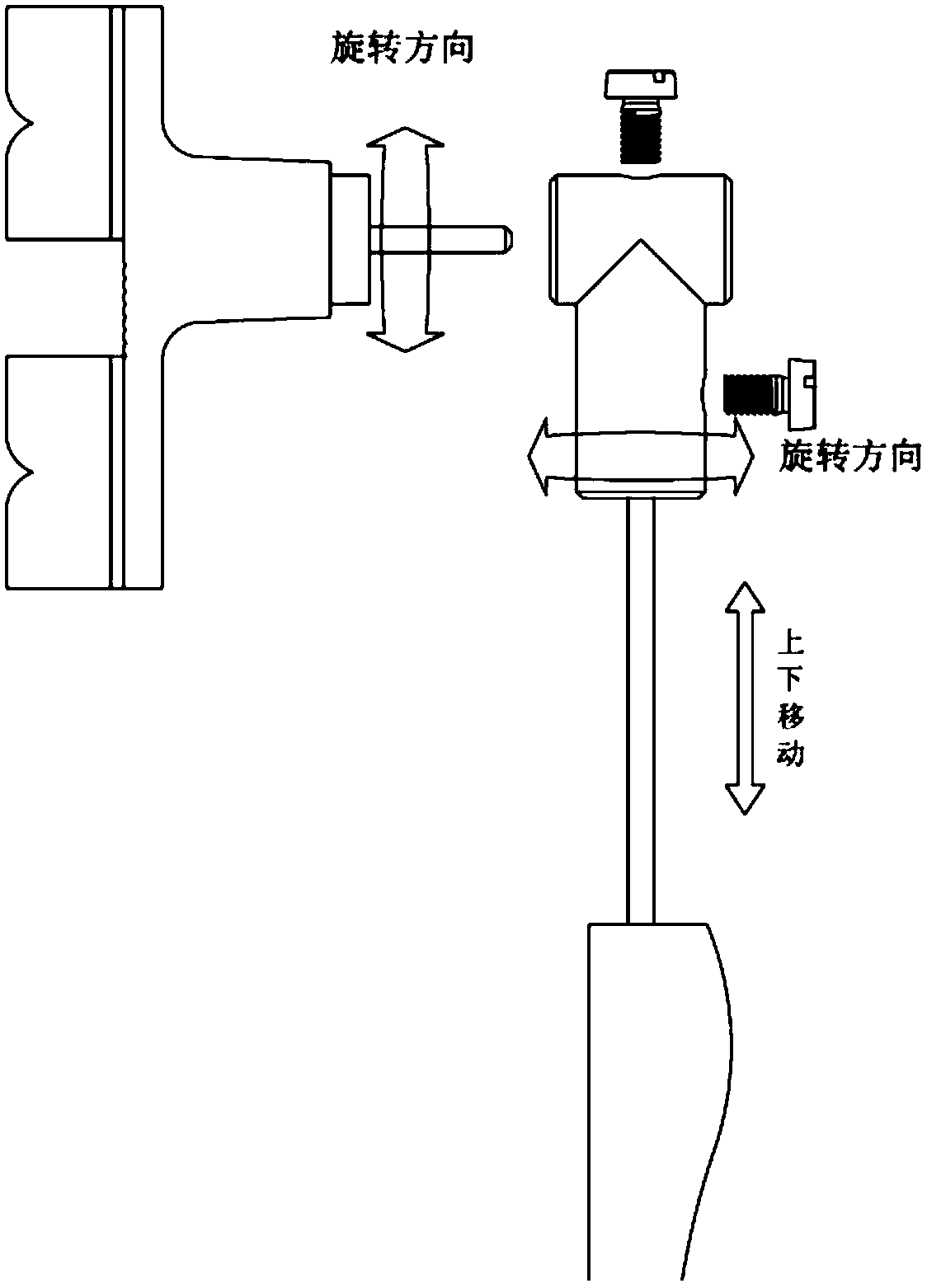

[0026] When it is necessary to align the strings, first loosen the first locking screw 4 so that the damper 2 can be rotated. When the damper 2 is aligned with the string 1, lock the first locking screw 4 again, and the completion of Stringing process.

[0027] When the tone knob 5 is adjusted in the direction of the damper screw 7, manually loosen the second locking screw 6, then move the tone knob 5 in the direction of the damper screw 7, and lock the second lock after the adjustment is completed. Tighten screw 6.

[0028] When the capsule button plate 3 needs to be replaced, it is only necessary to loosen the first locking screw 4 and remove the entire silencer 2, and then remove the capsule button plate 3 from the silencer 2 and replace it Just install a new one.

[0029] Brass inserts are installed on the head button 5, so that the locking force of the first locking screw 4 and the second locking screw 6 is stronger, which can be repeatedly opened and locked to avoid th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com