Variable-angle fixing test system for test piece in airplane discrete source impact damage test

A technology of impact damage and fixed testing, which is applied in impact testing, material strength testing using one impact force, and aircraft component testing. Stepless adjustment, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

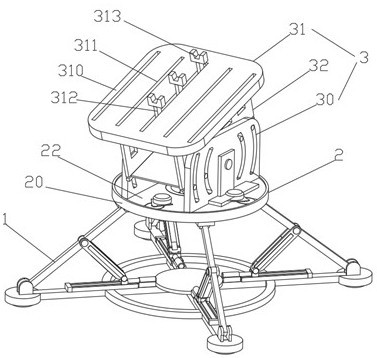

[0046] like figure 1 The shown test system for variable angle fixing of the test piece in the aircraft discrete source impact damage test includes a support device 1 arranged horizontally on the ground, and a variable angle fixing test bench arranged on the support device 1;

[0047] The variable-angle fixed test stand includes a first angle adjustment device 2 arranged on the support device 1, and a second angle adjustment device 3 movably arranged on the first angle adjustment device 2;

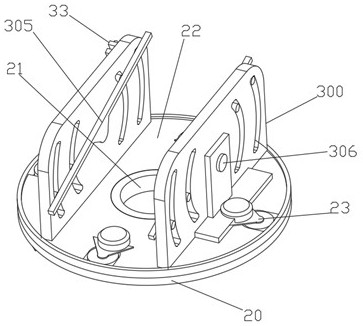

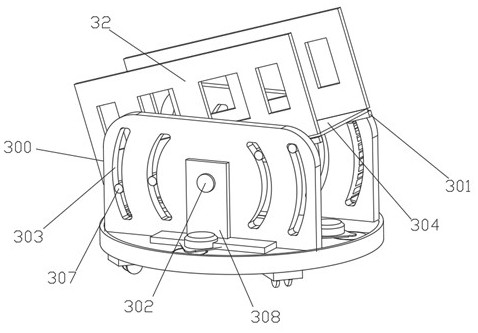

[0048] like figure 2 As shown, the first angle adjusting device 2 includes a circular connecting plate 20 fixedly arranged above the supporting device 1, an annular bushing 21 arranged in the center of the circular connecting plate 20, and movably arranged on the annular connecting plate 20. a rotating disk 22 on the shaft sleeve 21 and having the same diameter as the circular connecting disk 20, and a power assembly 23 arranged between the circular connecting disk 20 and the rotating dis...

Embodiment 2

[0059] The difference from Example 1 is:

[0060] like Figure 5 As shown, the support device 1 includes a bottom base plate 10 arranged on a level ground, an attitude adjustment assembly arranged on the bottom base plate 10 and connected with a circular connecting plate 20;

[0061] The bottom base plate 10 includes a central fixed plate 100 horizontally arranged on the ground, four extension rods 101 arranged on the central fixed plate 100 and evenly distributed along the radial direction of the central fixed plate 100, and a plurality of extension rods 101 are respectively arranged on the central fixed plate 100. the connecting seat 102 at the end of the extension rod 101;

[0062] The upper surface of the connection seat 102 is provided with a first connection lifting lug 103, and the lower surface of the connection seat 102 is provided with a grounding fixing component 106;

[0063] Four second connecting lugs 104 corresponding to the first connecting lugs 103 are movab...

Embodiment 3

[0070] The difference from Example 2 is:

[0071] like Figure 7 As shown, the adjusting rod 113 includes an I-shaped adjusting rod 114 whose upper end is hinged with the support rod 110, and a U-shaped sliding rod 115, which is slidably arranged on the I-shaped adjusting rod 114 and whose lower end is hinged with the hydraulic push cylinder 112;

[0072] The I-shaped adjusting rod 114 is provided with a locking rack; the U-shaped sliding rod 115 is provided with a ratchet device 116 connected with the locking rack.

[0073] A hinged connection piece 117 is provided at the connection between the hydraulic push cylinder 112 and the U-shaped sliding rod 115;

[0074] The upper surface of the extension rod 101 is provided with a limiting groove 118;

[0075] The hinged connection member 117 is slidably disposed on the limiting groove 118 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com