Membrane-free oxygen-free direct methanol fuel cell with three-dimensional gradient structure anode and preparation method

A methanol fuel cell and gradient structure technology, applied in battery electrodes, structural parts, circuits, etc., can solve the problems of methanol fuel waste, increased battery cost, and reduced battery performance, so as to improve performance, catalyst utilization, and catalyst consumption. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

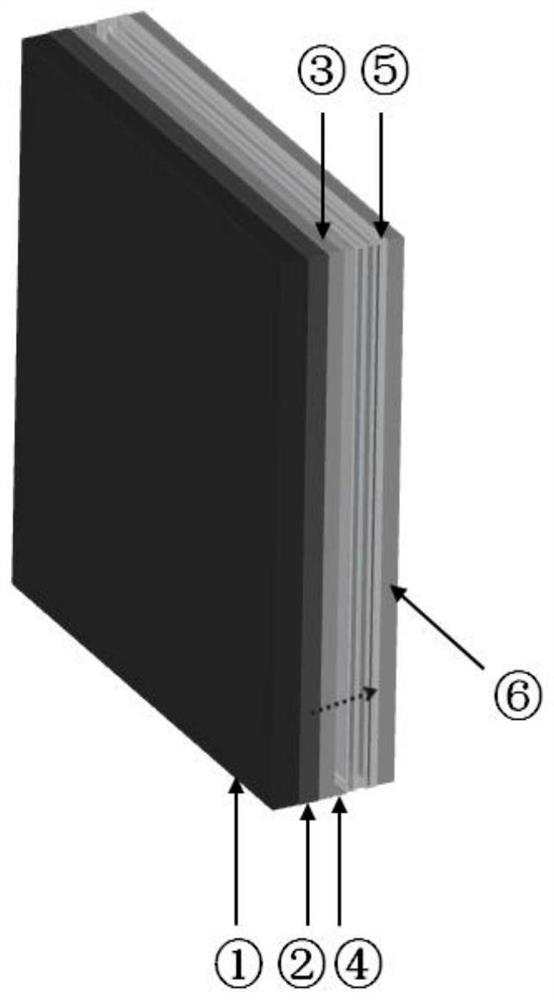

[0030] Such as figure 1 As shown, cut the appropriate size of the anode diffusion layer for processing. Weighed 22 mg, 12 mg, and 7 mg of PtRuAu / C catalysts with metal loadings of 80%, 60%, and 40%, respectively, mixed them with 100 μL Nafion emulsion and 900 μL deionized water, and dispersed them ultrasonically for 6 hours to form a uniform catalyst slurry. Weigh the mass m of the bare anode diffusion layer (①) 0 , the PtRuAu / C catalyst slurry with a metal loading of 80% was coated on the anode diffusion layer, and then dried in a vacuum oven to obtain the first catalytic layer CL 1 (②), weigh its mass m 1 , get CL 1 The loading capacity of the upper catalyst is 10.0mg / cm 2 ; PtRuAu / C catalyst slurry with 60% metal loading was coated on CL 1 and placed in a vacuum oven to dry to obtain the second catalytic layer CL 2 (③), call its mass m 2 , get CL 2 The loading amount of the upper catalyst is 5.0mg / cm 2 ; PtRuAu / C catalyst slurry with 40% metal loading was coated on...

Embodiment 2

[0034]Cut the appropriate size of the anode diffusion layer for processing. Weighed 20 mg and 10 mg of PtRuAu / C catalysts with metal loadings of 70% and 40%, respectively, mixed with 100 μL Nafion emulsion and 900 μL deionized water, and then ultrasonically dispersed for 4 h to form a uniform catalyst slurry. Weigh the mass m of the bare anode diffusion layer 0 , the PtRuAu / C catalyst slurry with a metal loading of 70% was coated on the anode diffusion layer, and then dried in a vacuum oven to obtain the first catalytic layer CL 1 , weigh its mass m 1 , get CL 1 The loading capacity of the upper catalyst is 9.0mg / cm 2 ; PtRuAu / C catalyst slurry with 40% metal loading was coated on CL 1 and placed in a vacuum oven to dry to obtain the second catalytic layer CL 2 , call its mass m 2 , get CL 2 The loading amount of the upper catalyst is 5.0mg / cm 2 , thus making a three-dimensional gradient structure anode.

[0035] Mix 18 mg of carbon black powder with 100 μL mL Nafion ...

Embodiment 3

[0038] Cut the appropriate size of the anode diffusion layer for processing. Weighed 15 mg, 6 mg, and 2 mg of PtRuAu / C catalysts with metal loadings of 70%, 60%, and 40%, respectively, mixed them with 100 μL Nafion emulsion and 900 μL deionized water, and dispersed them ultrasonically for 5 h to form a uniform catalyst slurry. Weigh the mass m of the bare anode diffusion layer 0 , the PtRuAu / C catalyst slurry with a metal loading of 70% was coated on the anode diffusion layer, and then dried in a vacuum oven to obtain the first catalytic layer CL 1 , weigh its mass m 1 , get CL 1 The loading amount of the upper catalyst is 7.0mg / cm 2 ; PtRuAu / C catalyst slurry with 60% metal loading was coated on CL 1 and placed in a vacuum oven to dry to obtain the second catalytic layer CL 2 , call its mass m 2 , get CL 2 The loading amount of the upper catalyst is 3.0mg / cm 2 ; PtRuAu / C catalyst slurry with 40% metal loading was coated on CL 2 and placed in a vacuum oven to dry to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com