Cross-shaped steel structure reinforcing rib

A technology of reinforcing ribs and steel structures, which is applied in the direction of building components, building structures, and earthquake resistance. It can solve the problems of not being easy to replace, reducing the stiffness and strength of reinforcing ribs, and reducing the service life of products, so as to achieve the effect of strengthening anti-vibration and causing shedding. Ability to eliminate excessive stress concentration and avoid potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

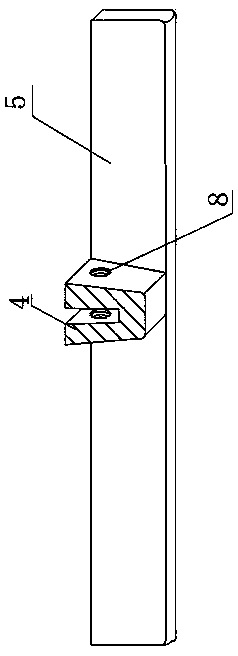

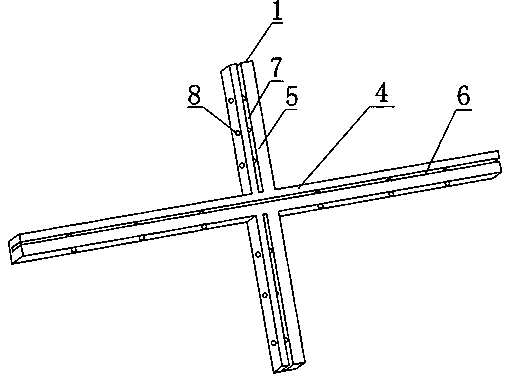

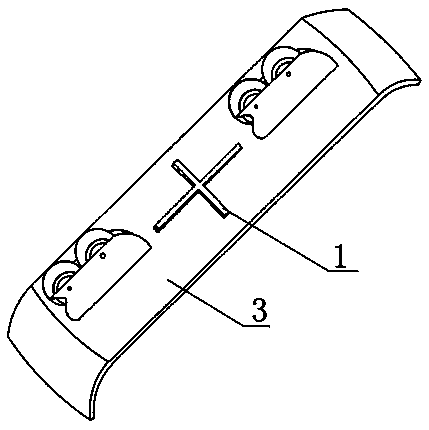

[0024] see Figure 1~5 , in the embodiment of the present invention, a cross-shaped steel structure reinforcing bar, including a reinforcing bar body 1 and a roller skating unit 3, is characterized in that: the reinforcing bar body 1 includes a main rib 4, and a main rib groove 6 is arranged inside the main rib 4, And both sides of the main rib 4 are provided with auxiliary ribs 5, the inside of the auxiliary rib 5 is provided with an auxiliary rib groove 7, the main rib 4 and the auxiliary rib 5 are all provided with a first through hole 8, the rib body 1 and the roller skating unit 3 A fastening mechanism 12 is provided at the joint.

[0025] In order to realize the detachable replacement of the rib body 1, in this embodiment, preferably, the main rib 4 and the auxiliary rib 5 are vertically welded into a cross shape, and the first through holes 8 are equidistant on the main rib 4 and the auxiliary rib 5 Symmetrically distributed, the main rib 4 and the auxiliary rib 5 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com