Red heart K-type microreactor

A technology of micro-reactor and micro-reaction chamber, which is applied in chemical/physical/physical-chemical reactors, chemical instruments and methods, chemical/physical/physical-chemical processes, etc., can solve the problem of incomplete mixing of reactants and achieve operational Convenient, easy-to-precise control over effects

Pending Publication Date: 2018-12-28

NANJING ZHENGYUAN ENAMEL EQUIP MFG

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

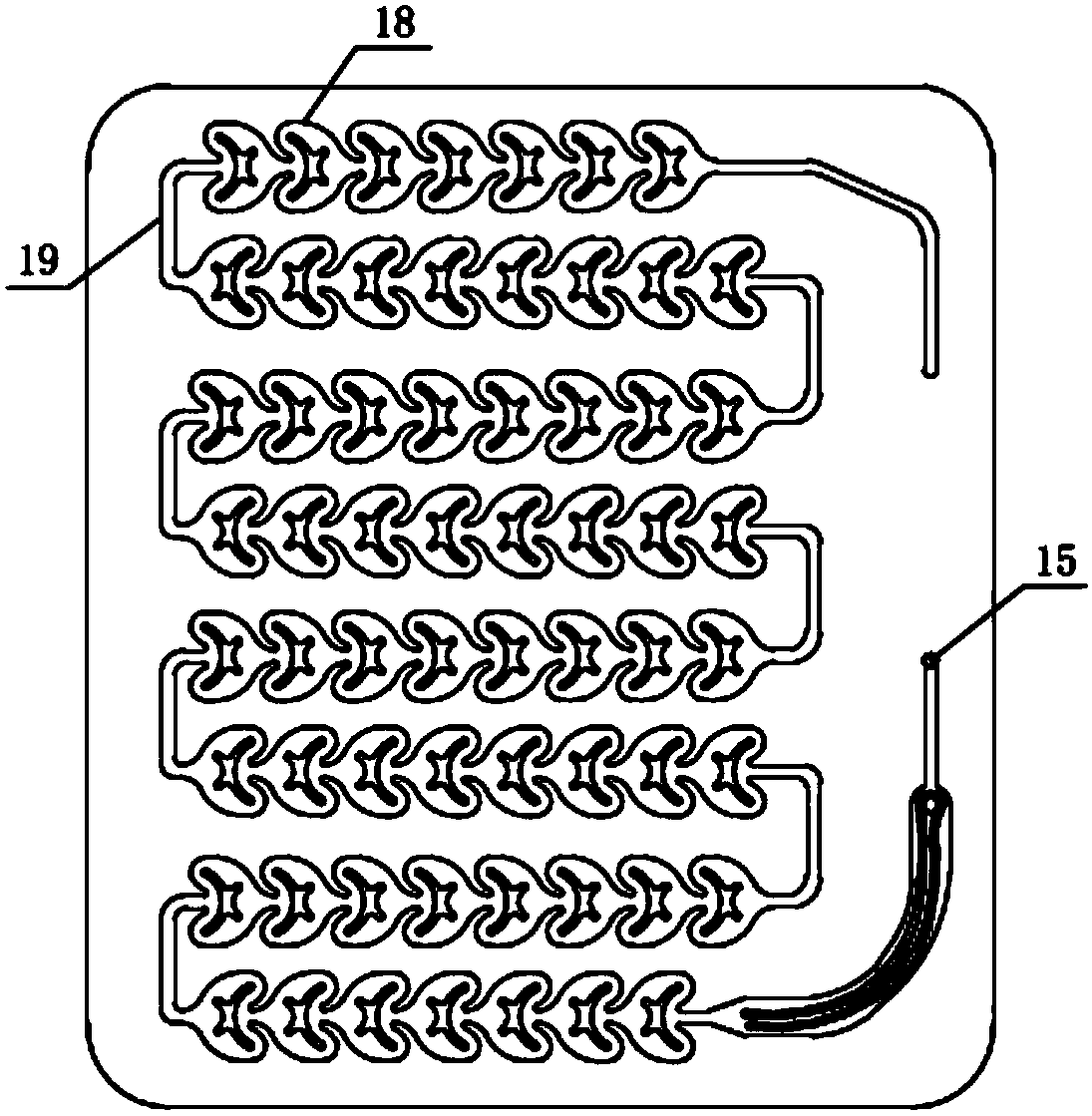

1. Most of the reaction plate flow channels are generally arranged in a sausage shape. There is no pressure design during the reaction process, and the reactants cannot be fully mixed.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

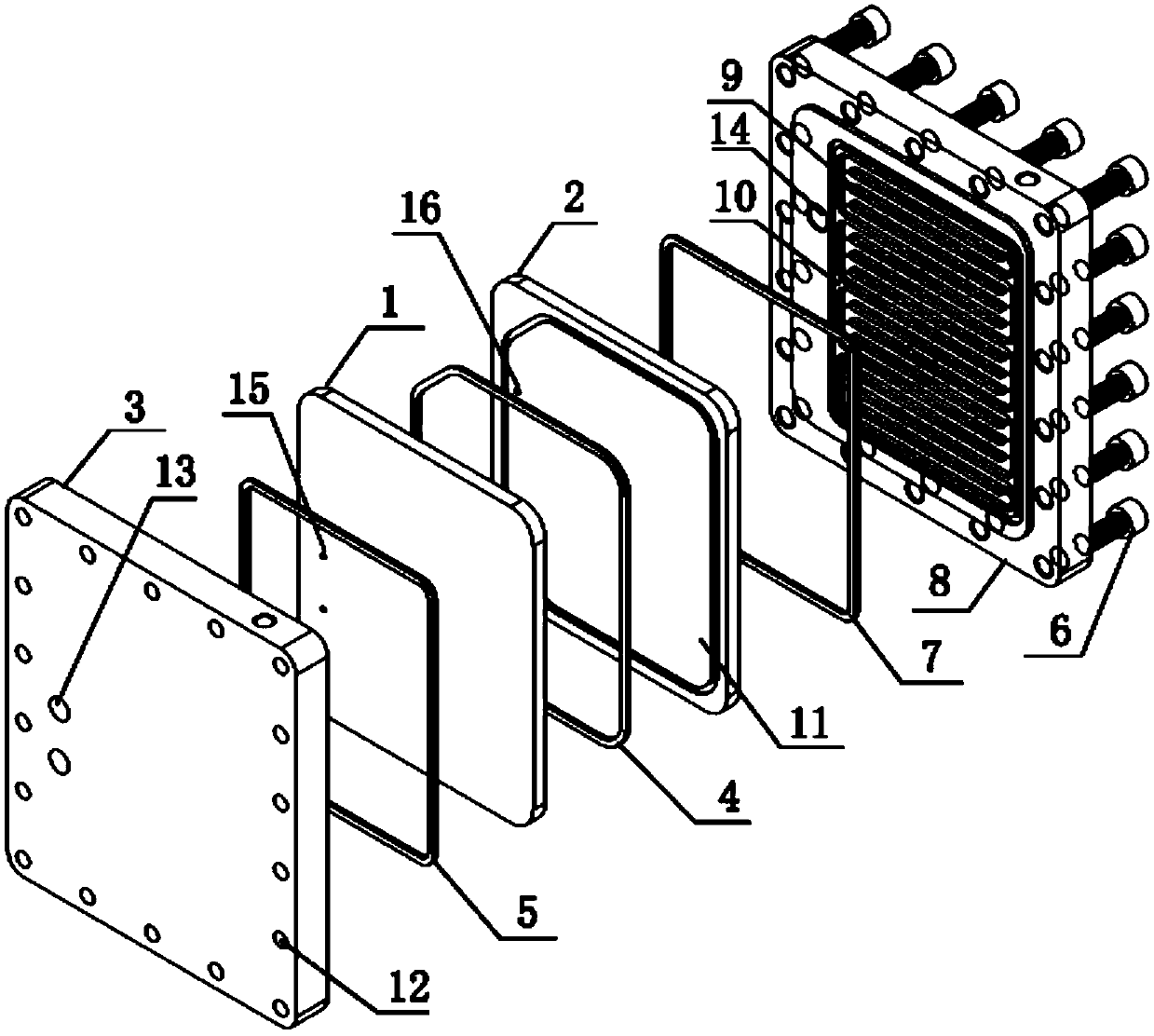

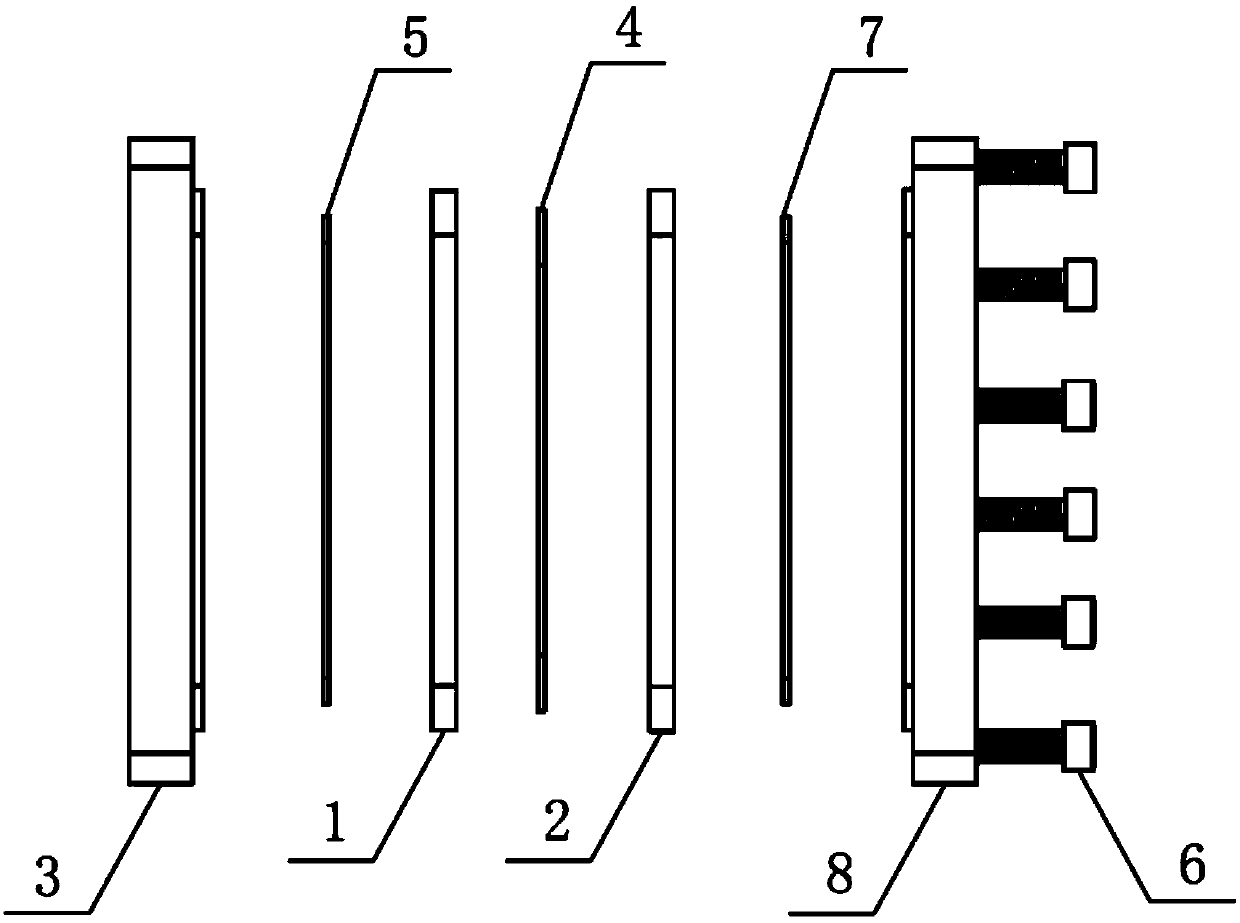

The invention discloses a red heart K-type microreactor. The red heart K-type microreactor comprises a reaction plate, a cover plate, a first heat exchange plate and a second heat exchange plate, wherein a second semi-through groove comprises a plurality of red heart microreaction chambers and a channel used for communicating the red heart microreaction chambers mutually, K-type drainage blocks are arranged inside the red heart microreaction chambers, a second sealing groove is opened on the lateral surface of the cover plate, first semi-through grooves arranged in the shape of intestines areopened all on the lateral surfaces of the first heat exchange plate and the second heat exchange plate, first sealing grooves are opened on the outer sides of the first semi-through grooves, and the first heat exchange plate, the reaction plate, the cover plate and the second heat exchange plate are closely assembled through bolts. The microreactor adopts a red heart K-type flow channel structuredesign, and multistage pressurization and backmixing can be performed during the reaction process, so that reactants can be fully crushed and mixed to fully react. The microreactor is connected and assembled by using a bolt structure, and further sealed through fluororubber and perfluororubber seal rings.

Description

technical field The invention relates to the technical field of microreactors, in particular to a red heart K-type microreactor. Background technique Since the 1990s, an important trend in the development of natural science and engineering technology is to move towards miniaturization, and micro chemical equipment has gradually developed. , energy, environment and other fields have been widely used. Its core component is a microchemical system manufactured entirely or partially by micromachining technology, and the characteristic scale of the channel is in the range of several microns to hundreds of microns. For different application backgrounds, microchemical devices with various functions have been derived, such as micro-total analysis systems, micro-heat exchangers, micro-mixers, micro-reactors, etc., among which micro-reactors have the most extensive application prospects. Microreactor has the advantages of simple structure, no amplification effect, easy control of ope...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01J19/00

CPCB01J19/0013B01J19/0073B01J19/0093B01J2219/00873B01J2219/00867B01J2219/0099

Inventor 尹光凯杨坤

Owner NANJING ZHENGYUAN ENAMEL EQUIP MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com