LED (light emitting diode) quick drying coating line

A coating line and second-dry technology, which is applied in spraying devices, spray booths, etc., can solve the problems of sticking to materials and affecting the spraying effect, and achieve the effect of improving the spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical scheme of the present invention will be further described below in conjunction with accompanying drawing and embodiment:

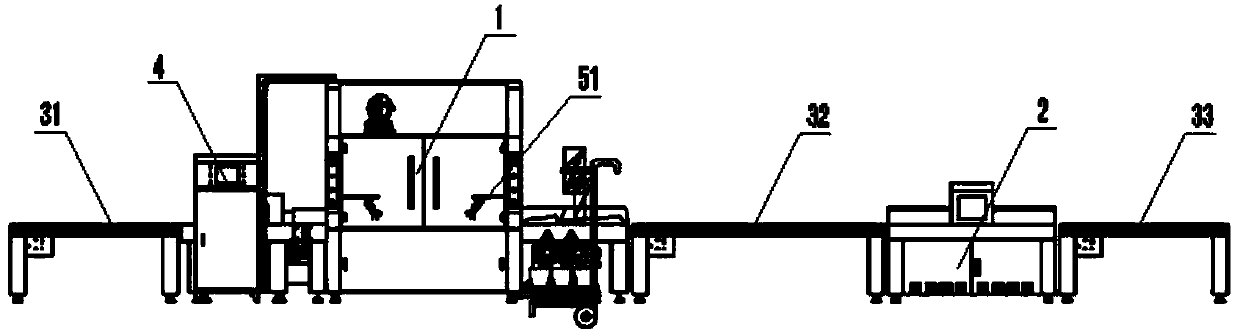

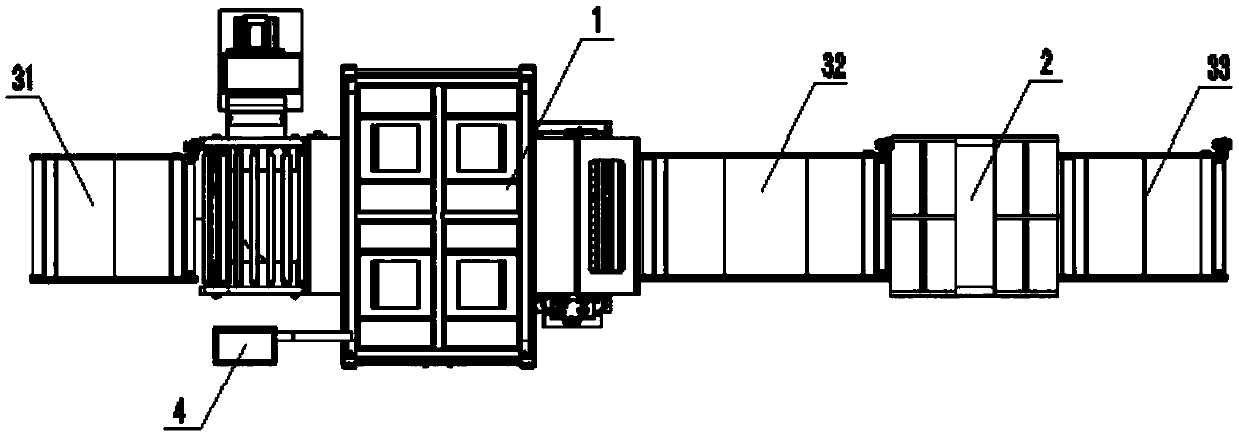

[0025] as attached figure 1 And attached figure 2 A kind of LED second dry coating line shown, comprises first feeder 31, reciprocating spraying machine 1, second feeder 32, curing machine 2, the 3rd feeder 33 and the first feeder 31 that are arranged in sequence , the controller 4 connected to the reciprocating spraying machine 1, the second feeder 32, the curing machine 2 and the third feeder 33. The controller 4 can simultaneously control the operation of the first feeder 31 , the reciprocating spraying machine 1 , the second feeder 32 , the curing machine 2 and the third feeder 33 . The curing machine 2 is preferably an LED light curing machine.

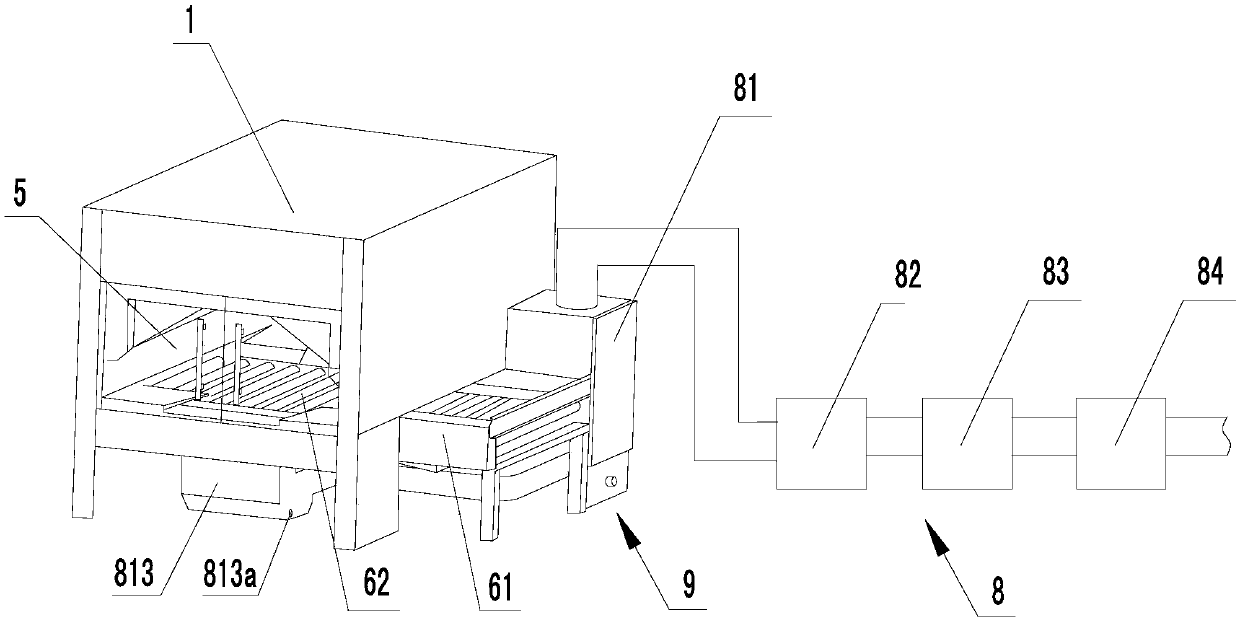

[0026] as attached image 3 As shown, the reciprocating spraying machine 1 includes a spraying chamber, a spraying mechanism 5 located in the spraying chamber, a conveying mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com