Self-locking sliding block device applied to injection mold

A technology of injection mold and slider, which is applied in the field of self-locking slider device, can solve the problem of product reaction force formed by shovel foundation, reduce mold production cost, mold molding cycle and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

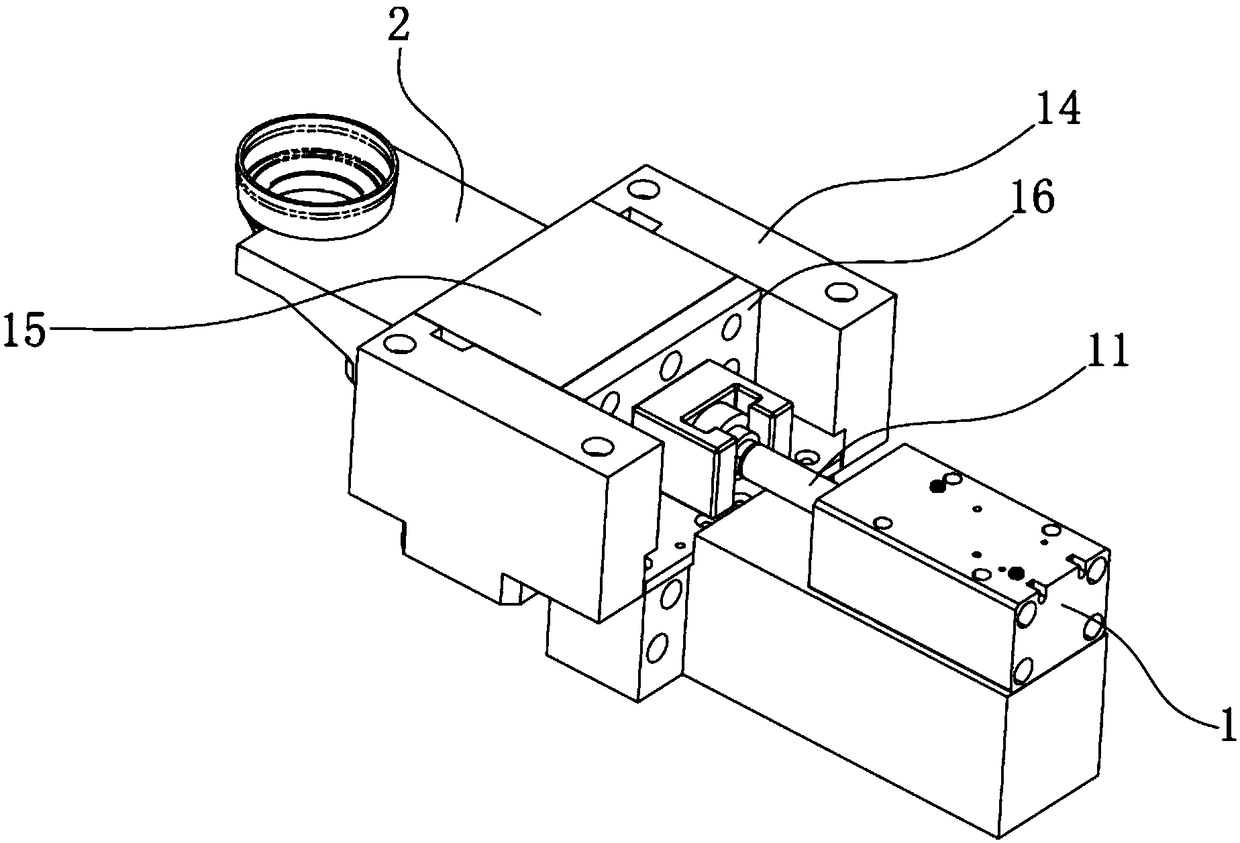

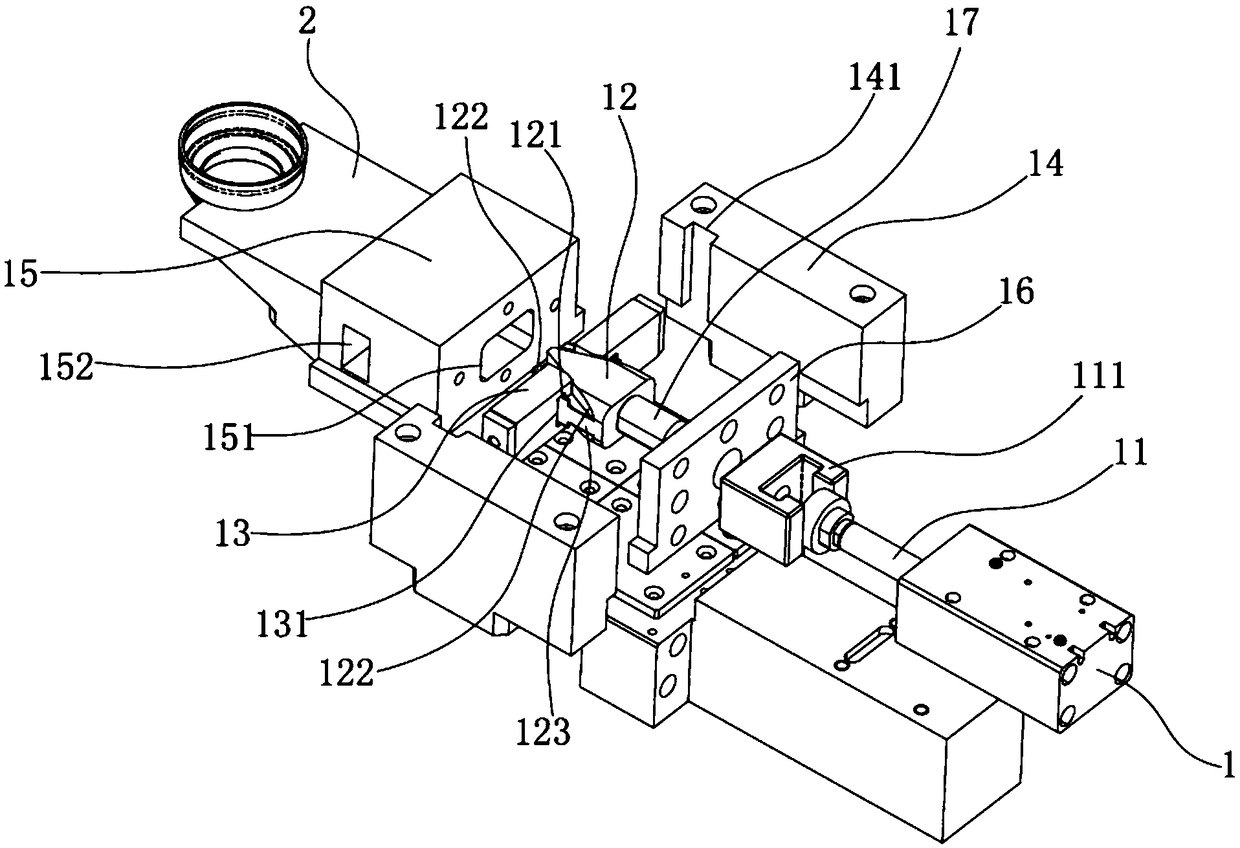

[0023] see Figure 1 to Figure 2 , the figure shows a self-locking slider device applied to injection molds provided by Embodiment 1 of the present invention, which includes a linear drive device 1, which may specifically be an oil cylinder, and the drive shaft 11 of the linear drive device 1 is fixedly connected to There is a latch dial 12, two paddles 121 are arranged on opposite sides of the latch dial 12 respectively, the paddles 121 are V-shaped paddles, which have an open end 122, and the latch 13 is set on the paddle 121, and the latch 13 is There is a preset first through hole 131, the plectrum 121 can be movably inserted into the first through hole 131 from its open end 122, and two pressing bars 14 are respectively arranged on the opposite sides of the latch shifting block 12, and the inside of the pressing bar 14 The side is provided with a self-locking groove 141, and the end of the latch 13 is self-lockingly matched with the self-locking groove 141, and the end of...

Embodiment 2

[0029] see Figure 1 to Figure 2 , the figure shows a self-locking slider device applied to injection molds provided by Embodiment 2 of the present invention. On the basis of the above embodiments, this embodiment further makes the following technical solutions as improvements: latch The end of shifting block 12 is connected with slide block 15, and slide block 15 is fixedly connected with product forming mold 2; There is hole body 151 for latch shift block 12 to enter on slide block 15, and hole body 151 is a blind hole. Through the setting of the above structure, the installation of the latch shifting block can be made more stable, and the stroke can be more precise.

Embodiment 3

[0031] see Figure 1 to Figure 2 , the figure shows a self-locking slider device applied to injection molds provided by Embodiment 3 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above embodiments: sliding The block 15 is a rectangular slider, and the opposite sides of the slider 15 are respectively provided with two second through holes 152, the second through holes 152 communicate with the hole body 151, the second through holes 152 are perpendicular to the hole body 151, and the latch 13 is in the second Move back and forth in the through hole 152 . Through the setting of the above structure, the installation of the bolt can be made more stable, and the stroke can be more precise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com