Auxiliary drive device

一种辅助驱动、四轮驱动的技术,应用在动力装置、电动力装置、控制装置等方向,能够解决工作延迟时间变长、驾驶者或同乘者不愉快感、大振动或声音等问题,达到降低振动的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described with reference to the drawings.

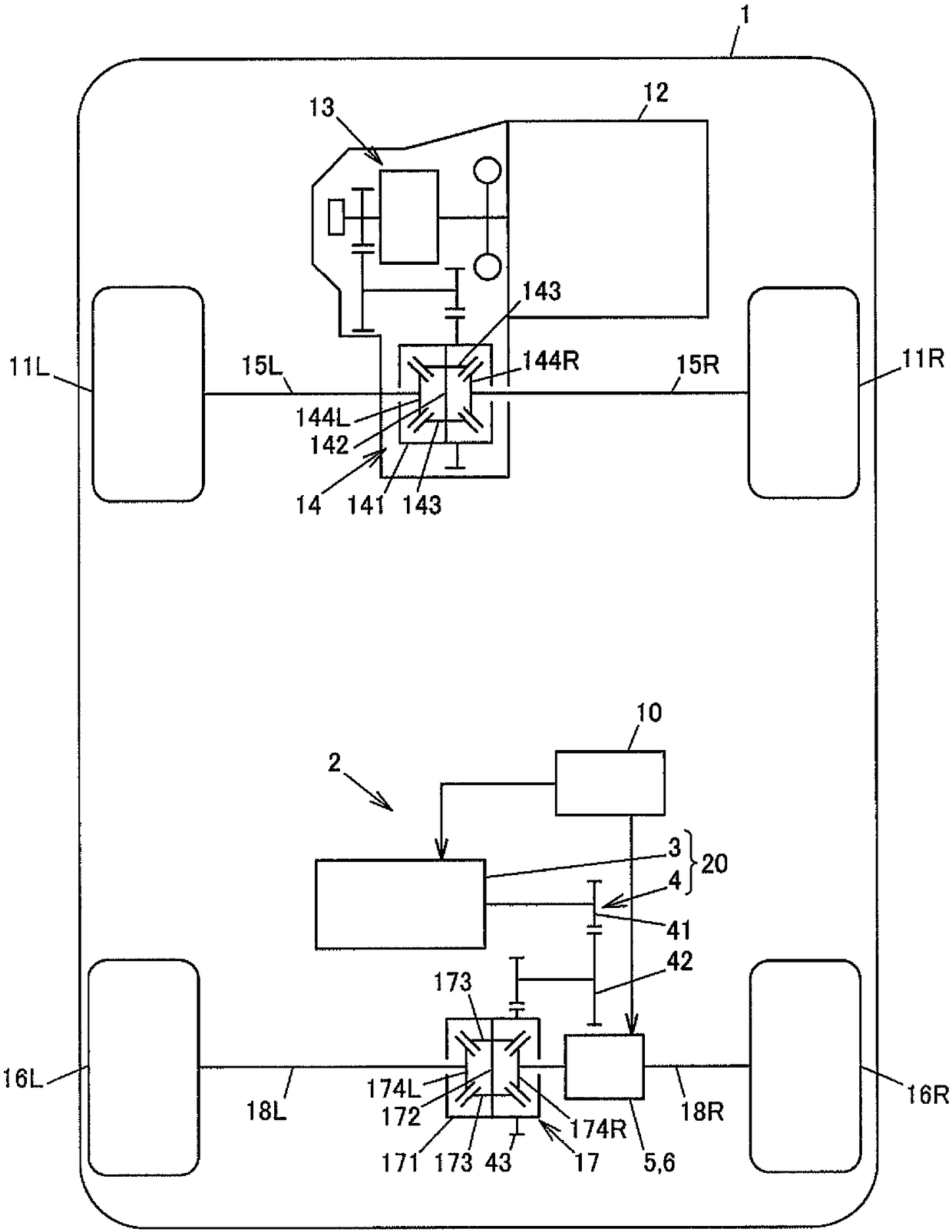

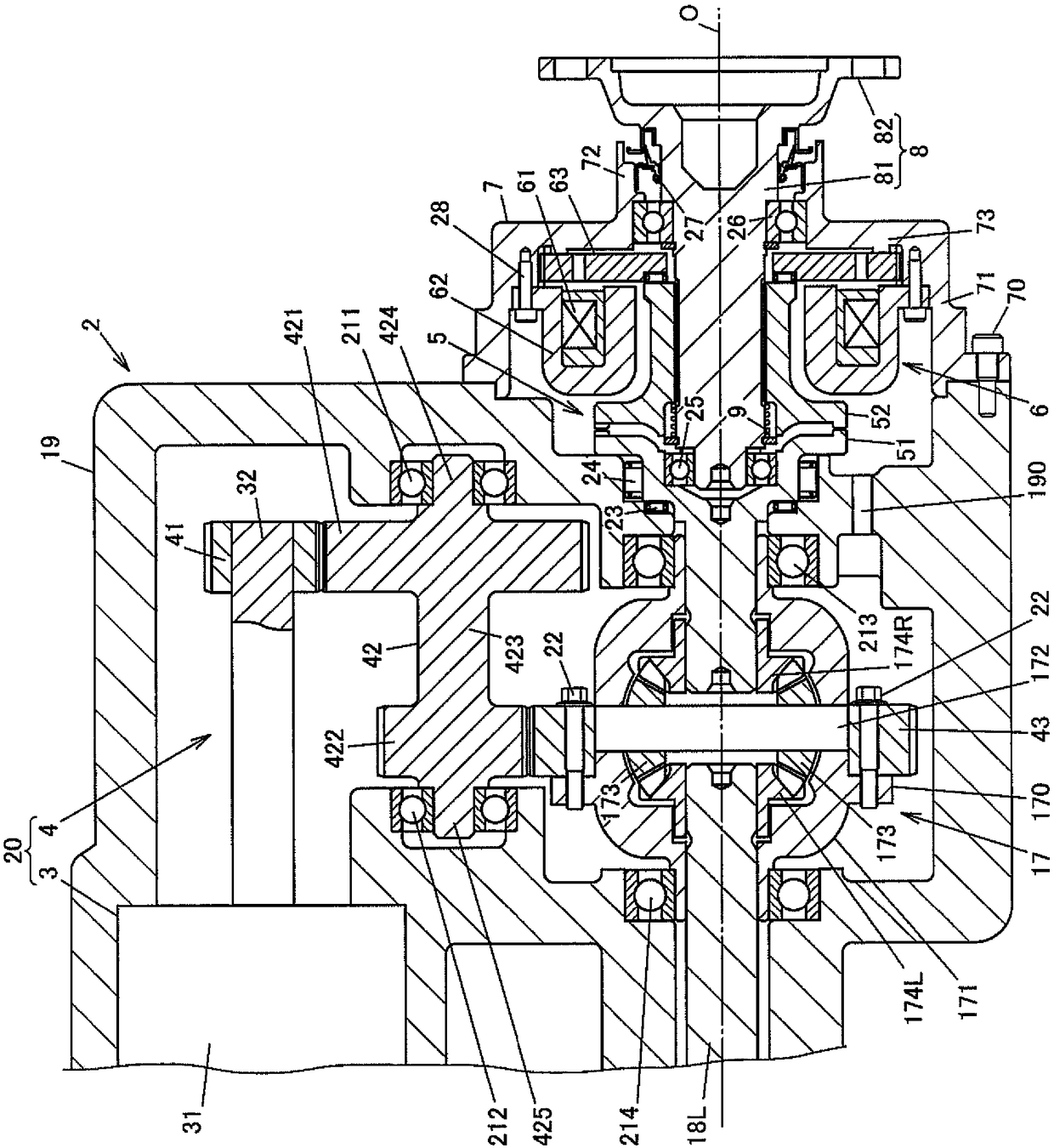

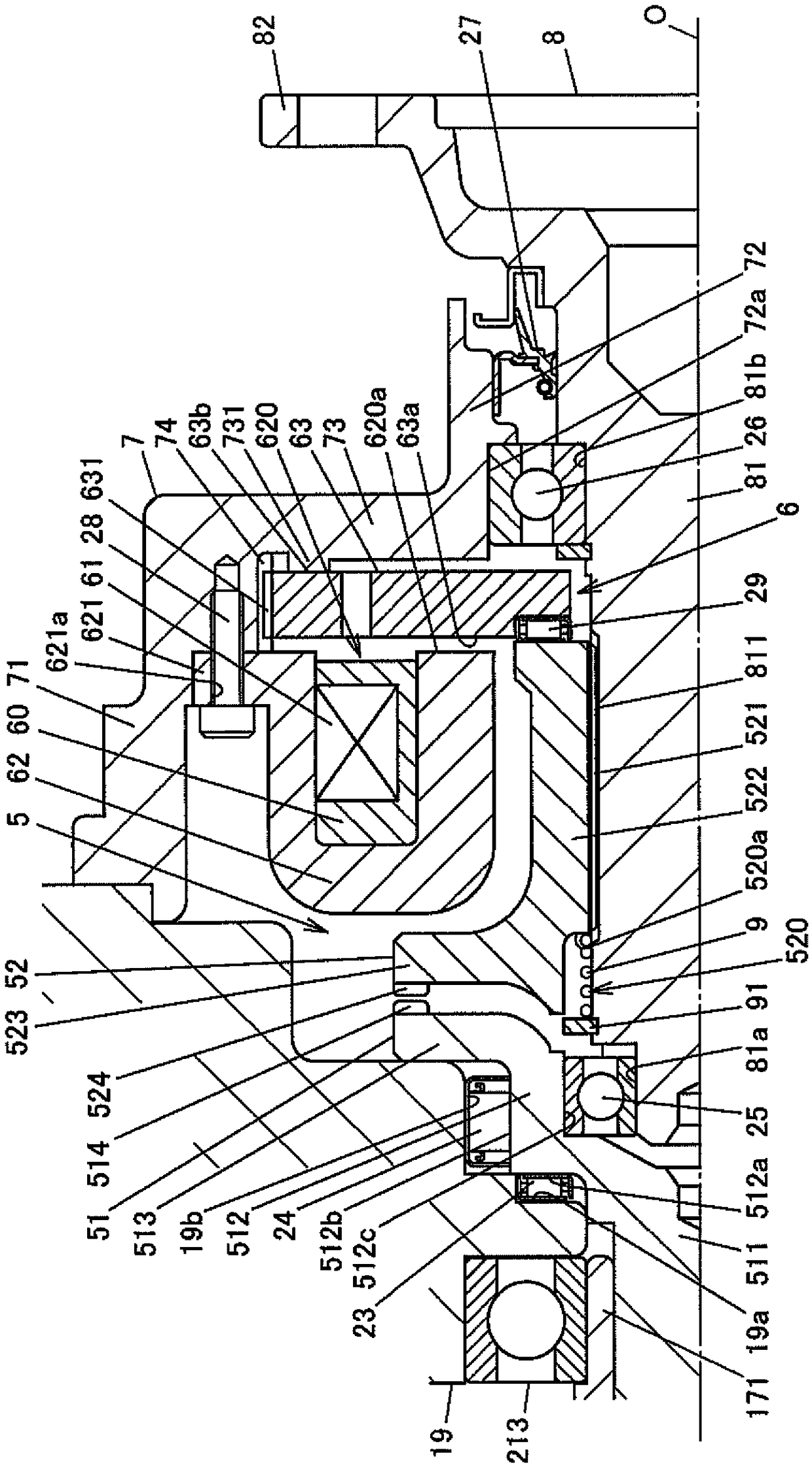

[0024] figure 1 It is a schematic diagram showing a configuration example of a four-wheel drive vehicle equipped with an auxiliary drive device according to an embodiment of the present invention. figure 2 It is a sectional view showing a structural example of the driving force transmission device. image 3 Indicates the main part of the driving force transmission device figure 2 A partial enlargement of the .

[0025] The left and right front wheels 11L, 11R of the four-wheel drive vehicle 1 are driven by an engine 12 serving as a main drive source, and the left and right rear wheels 16L, 16R are driven by an auxiliary drive device 2 having an electric motor 3 . In the present embodiment, the left and right front wheels 11L, 11R are main drive wheels, and the left and right rear wheels 16L, 16R are auxiliary drive wheels. In the following description, "left" and "right" refer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com