A split pet feeder

A feeder and split-type technology, which is applied to animal feeding devices, animal houses, animal taming devices, etc., can solve the problems of center of gravity deviation, damage, uneven distribution of food weight, etc., to avoid material jams and prevent The effect of pouring and falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

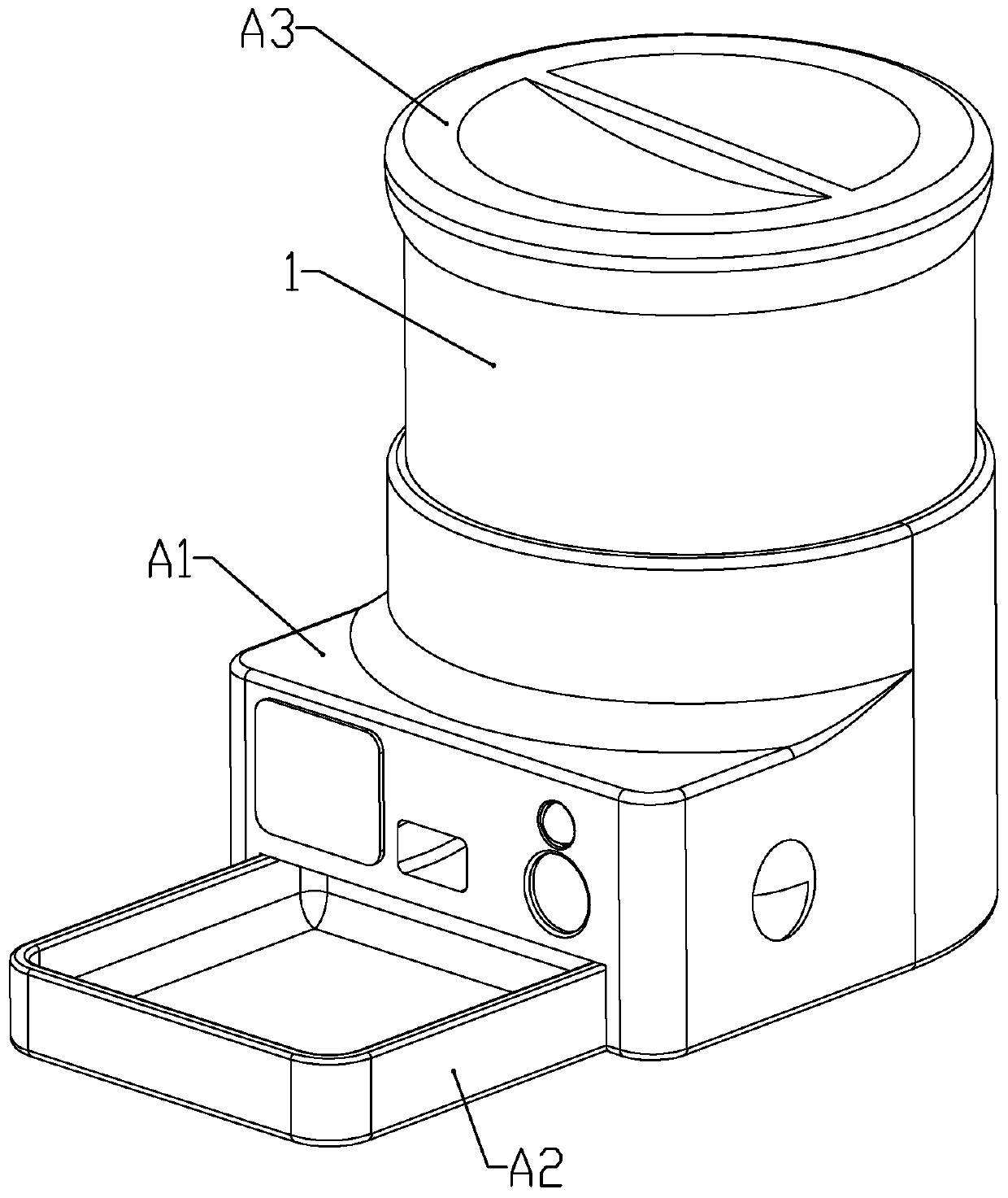

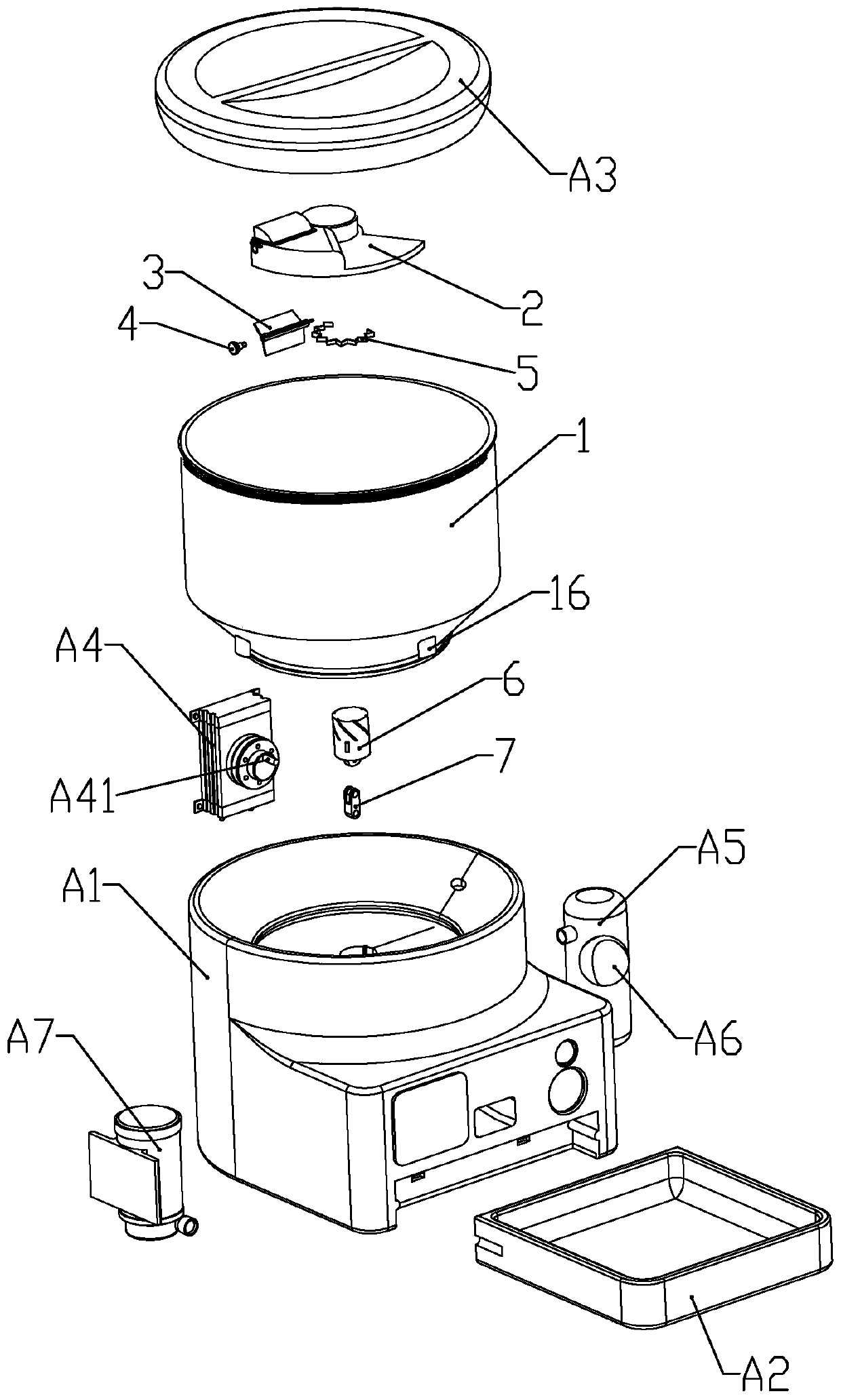

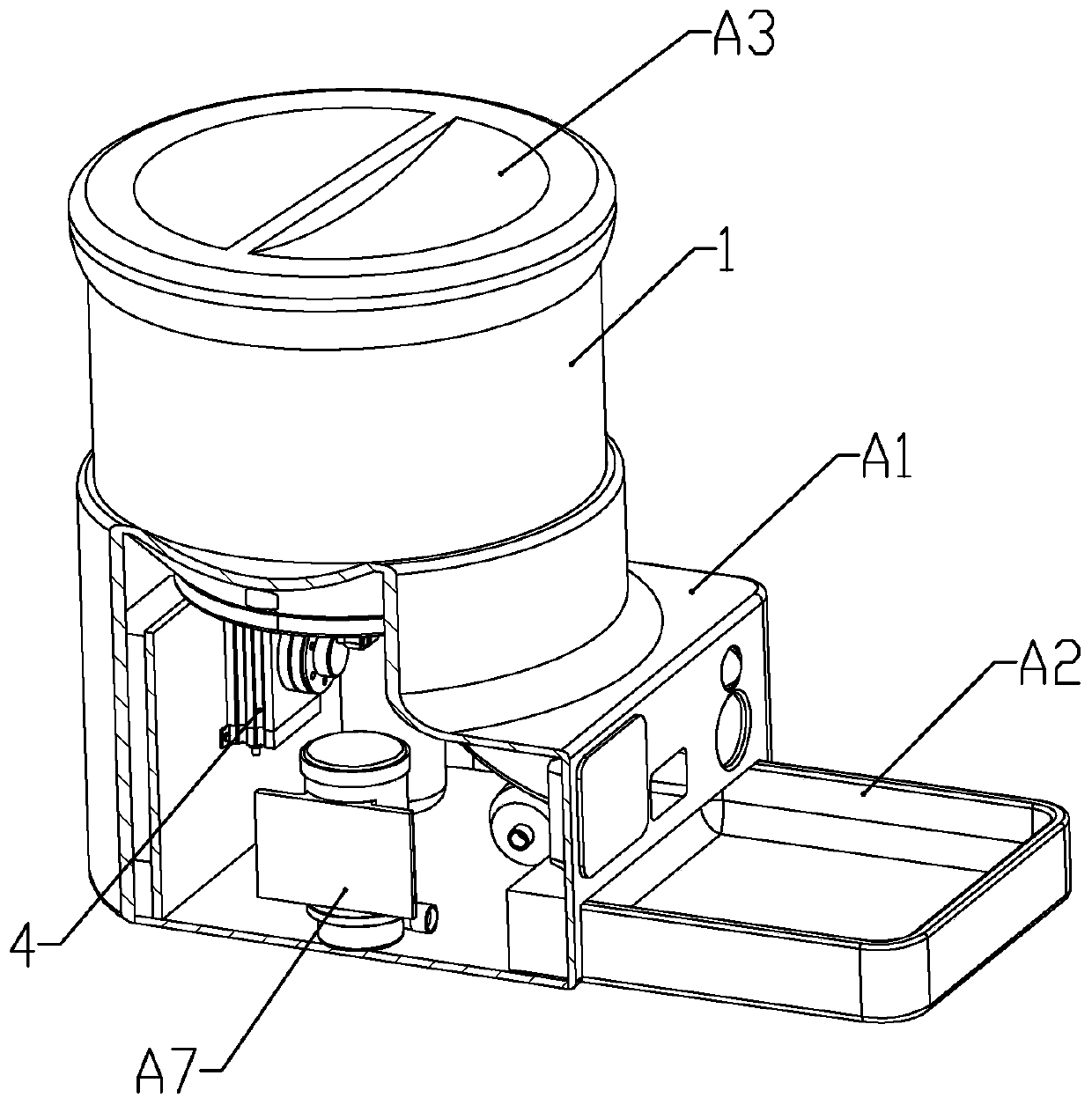

[0042] according to Figure 1 to Figure 8 As shown, a split-type pet feeder described in this embodiment includes a base A1, a barrel 1 detachably installed on the upper end of the base, and a top cover A3 that is movably and sealingly connected to the upper end of the barrel; A food tray A2 is detachably mounted on the lower part of the front end of the base; a booster air pump A7 is installed in the base.

[0043] The lower part of the barrel is in the shape of a truncated cone with a large top and a small bottom; a through hole 11 is formed in the center of the bottom of the barrel; a snap ring 12 is formed on the bottom of the barrel at the outer periphery of the through hole; the inner bottom of the barrel is A discharge turntable 2 is installed; the discharge turntable is fan-shaped; the discharge turntable includes a discharge plate 21 and a rotating shaft 22; the lower end of the rotating shaft is formed with a transmission cylinder 221 passing through the through hole...

Embodiment 2

[0062] A pet room described in this embodiment: includes a wall, a roof and a door; the pet feeder as described in Embodiment 1 is detachably installed outside the door; the outlet of the spray pipe faces the room. Outside the door; the roof extends to the top of the pet feeder; the outlet end of the booster air pump is connected to the inside of the wall through a pipeline, and the pipeline is installed with the controller electrically connected The electromagnetic valve.

[0063] By controlling the pet feeder, the pet can be fed and the toy ball can be sprayed for the pet to play, and the pet room can be dried by controlling the booster air pump and the solenoid valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com