Deformable spherical face eccentric valve

A valve and eccentric technology, which is applied in the field of deformed spherical eccentric valves, can solve the problems of large opening and closing torque, poor sealing performance, and short service life, and achieve the effects of good sealing performance, extended service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

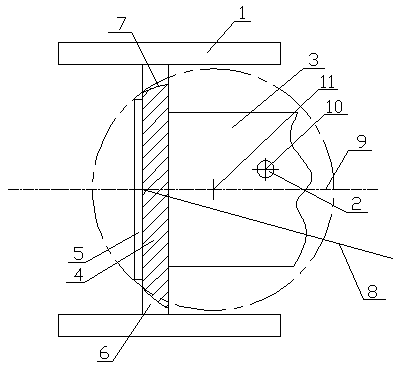

[0012] A deformed spherical eccentric valve, comprising a valve body 1, a valve stem 2 and an opening and closing member 3. The opening and closing member 3 is located in the valve body 1, and the valve stem 2 is connected to the opening and closing member 3, and the opening and closing member 3 is one An annular step is provided on the side, and a sealing ring 4 is installed on the annular step. The sealing ring 4 is fixed on the opening and closing member 3 by a pressure ring 5. The valve body 1 is provided with a valve seat 6, a valve seat 6 and a sealing ring 4 is closed to form a sealing surface 7, the sealing surface 7 is a curved surface, the radial section of the sealing surface 7 is a perfect circular section, and the oblique line 8 formed by the center of the perfect circular section forms an angle a with the centerline 9 of the valve flow channel. The plane formed by the line 8 and the valve flow channel centerline 9 is perpendicular to the valve stem axis line 10, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com