Five-dimensional eccentric valve sealing structure

A valve sealing and eccentric technology, applied in the direction of lift valve, valve device, cock including cut-off device, etc., can solve the problems of large opening and closing torque, high pressure, poor sealing performance, etc. Long service life and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

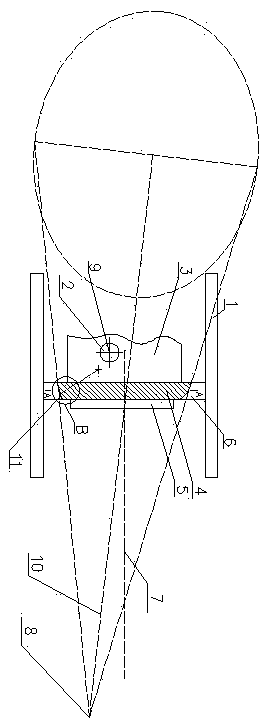

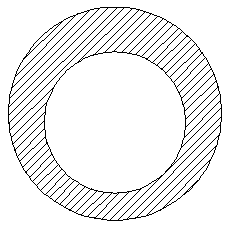

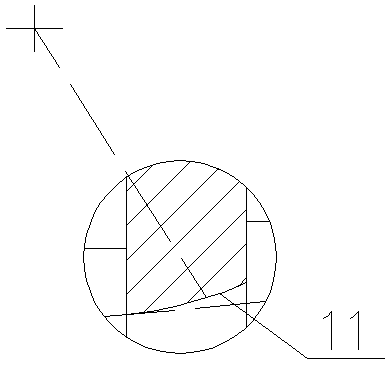

[0014] A five-dimensional eccentric valve sealing structure, including a valve body 1, a valve stem 2 and an opening and closing member 3, the opening and closing member 3 is located in the valve body 1, the valve stem 2 is connected to the opening and closing member 3, and the opening and closing member 3 One side of the closing part 3 is provided with an annular step, and a sealing ring 4 is installed on the annular step, and the sealing ring 4 is fixed on the opening and closing part 3 through the pressure ring 5, and the valve body 1 is provided with a valve seat 6, The valve seat 6 and the sealing ring 4 are closed to form a sealing surface, the sealing surface is an oblique elliptical cone perfect circle sealing surface, the sealing surface is an arc-shaped sealing surface, and the sealing surface is a 7 A part of the oblique oblique ellipse cone, the plane where the apex 8 of the oblique ellipse cone and the short axis of the ellipse bottom surface are co-located is copl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com