Isobaric partition adsorption workbench

A workbench and work platform technology, which is applied to the photoengraving process of the pattern surface, the exposure device of the photoengraving process, optics, etc., can solve the problems of PCB board failure and adsorption, and achieve the effect of the best suction cup partition effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides an isobaric partition adsorption workbench. The isobaric partition adsorption workbench comprises from top to bottom: a worktable surface, a work platform main body and a vacuum assembly; wherein, the work platform main body is divided into a plurality of concave In the lower area, the concave areas are divided by protruding steps to form multiple working areas; the working table is located above the main body of the working platform, and the two are in close contact; the bottom surface of each concave area is equipped with vacuum through holes;

[0028] There are several through holes on the working table;

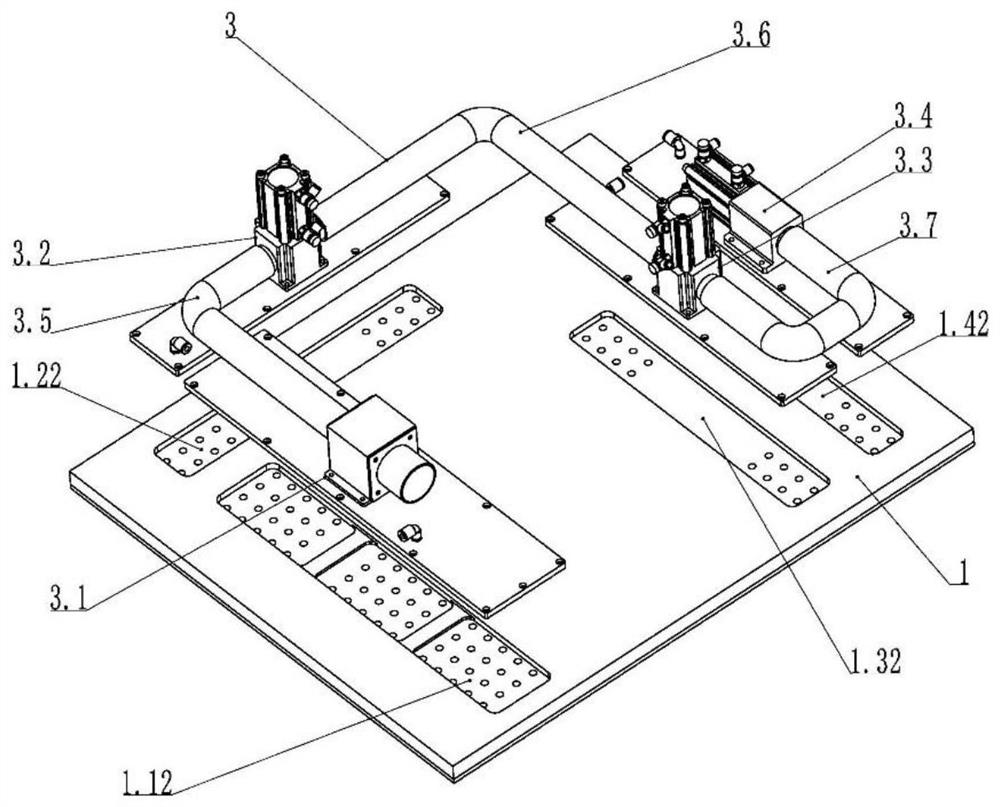

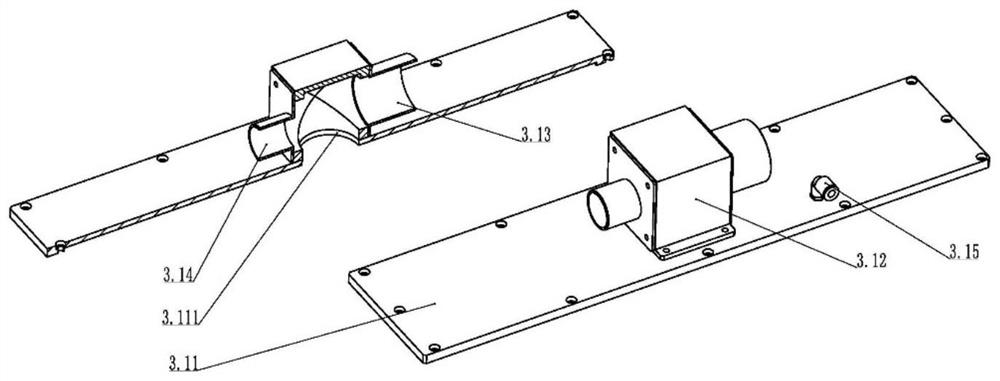

[0029] The vacuuming component includes a vacuuming pipeline and a plurality of vacuuming covering control components, and the vacuuming covering control component is used to control the vacuuming on and off of each working area;

[0030] The vacuum covering control assembly is located below the main body of the working platform; the two ar...

Embodiment 2

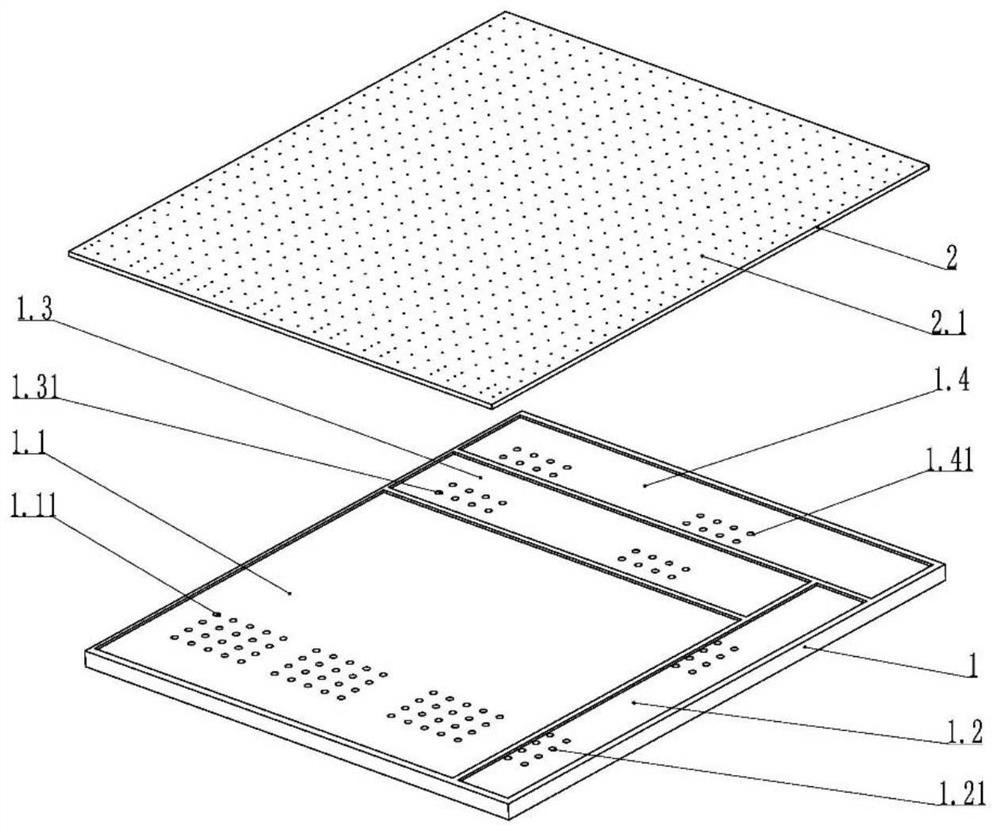

[0032] This embodiment provides an isobaric partition adsorption workbench, see figure 1 , figure 1 The schematic diagram of the working table and the main body of the working platform in the isobaric partition adsorption workbench provided for this application; 1.3 and 1.4. A working platform 2 is arranged above the working platform main body 1. The working platform main body 1 and the working platform 2 are in close contact. A plurality of independent spaces are formed by designing a concave area on the platform main body 1. Each independent concave area passes through a protruding The steps are divided, and each divided step is in close contact with the work surface 2 to ensure that no gas passes through; the bottom surface of each concave area is provided with a plurality of vacuum through holes 1.11, 1.21, 1.31 and 1.41.

[0033] The working surface 2 is provided with a plurality of through holes 2.1 for absorbing PCB boards.

[0034] Below the main body 1 of the worki...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com