Comprehensive shear tester for anchoring bodies and test method thereof

A technology of experimental device and experimental method, which is applied in the direction of measuring device, using stable shear force to test the strength of materials, instruments, etc., can solve the problems of not being targeted, not too economical and convenient, and not very meaningful in application , to achieve reliable experimental results, reduce shear fracture, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

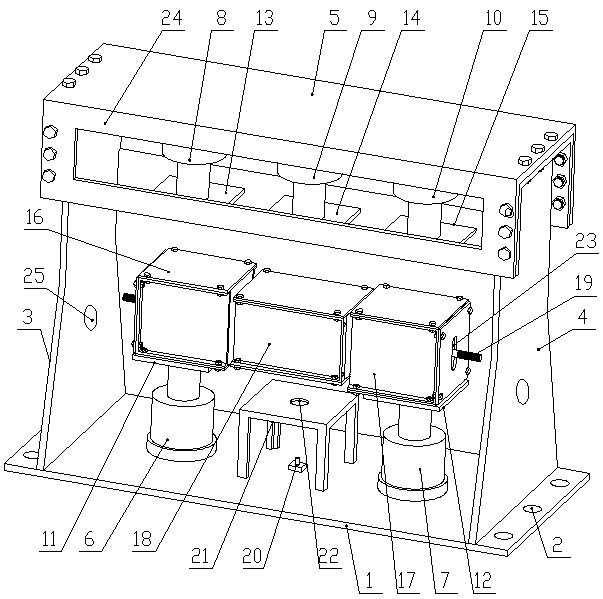

[0023] Such as figure 1 As shown, the comprehensive anchoring shear test device of the present invention includes a horizontally arranged base plate 1, the left and right sides of the base plate 1 are provided with anchor holes 2, and the base plate 1 is vertically arranged (welded) with a left vertical plate 3 and Right vertical plate 4, top plate 5 is arranged horizontally on the upper ends of left vertical plate 3 and right vertical plate 4, left jacking oil cylinder 6 and right jacking oil cylinder 7 are arranged on the upper surface of bottom plate 1, left lower pressing oil cylinder is fixedly arranged on the lower surface of top plate 5 8. The middle and lower pressure oil cylinder 9 and the right lower pressure oil cylinder 10, the left jacking oil cylinder 6 and the left lower pressure oil cylinder 8 are set up and down correspondingly, the right jacking oil cylinder 7 and the right down pressing oil cylinder 10 are set up and down correspondingly, and the telescoping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com