Design and implementation method of a waste discharge module

A technology for discharging modules and implementing methods, applied in design optimization/simulation, computing, instruments, etc., can solve problems such as high difficulty and environmental complexity, achieve speed and efficiency, improve design efficiency, improve design efficiency and rationality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

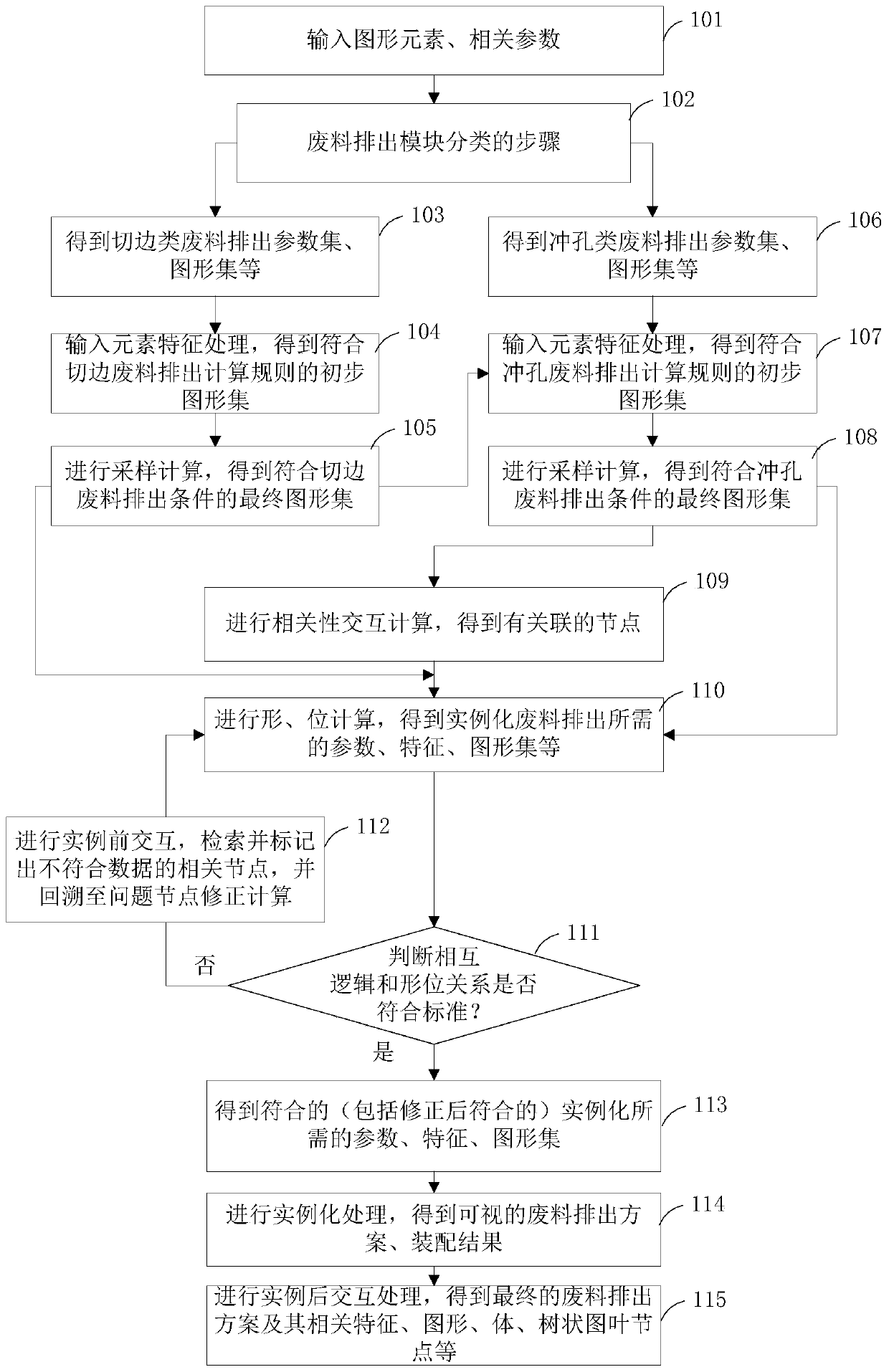

[0032] The method of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments of the present invention.

[0033] figure 1 It is a schematic flowchart of the design and implementation method of the waste discharge module in the embodiment of the present invention.

[0034] Such as figure 1 As shown, the design implementation method of the waste discharge module includes the following steps:

[0035] Step 101: Input graphic elements and related parameters. The graphic elements and related parameters include trimming set TS, waste cutting line LSC, drawing shrinkage line CBD, positive punching profile ZP, side punching profile CP, discharge direction VDOS and main frame type WPName.

[0036] Step 102: Carry out the step of classifying waste material discharge modules. For example, it can be classified according to F(Scrap_Type)=f(WPName), and can be divided into a punching type scrap discharge parameter set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com