Manufacturing method of single-input and double-outlet sound hole microphone substrate

A production method and microphone technology, which are applied in the direction of microphone port/microphone accessories, sensors, electrical components, etc., can solve the problems of differences in sound signals and occupy the internal space of products, so as to reduce product costs and improve sound pickup accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. However, the scope of protection of the present invention is not limited to the following examples, that is, any simple equivalent changes and modifications made based on the patent scope of the present invention and the content of the description are still within the scope of the patent of the present invention.

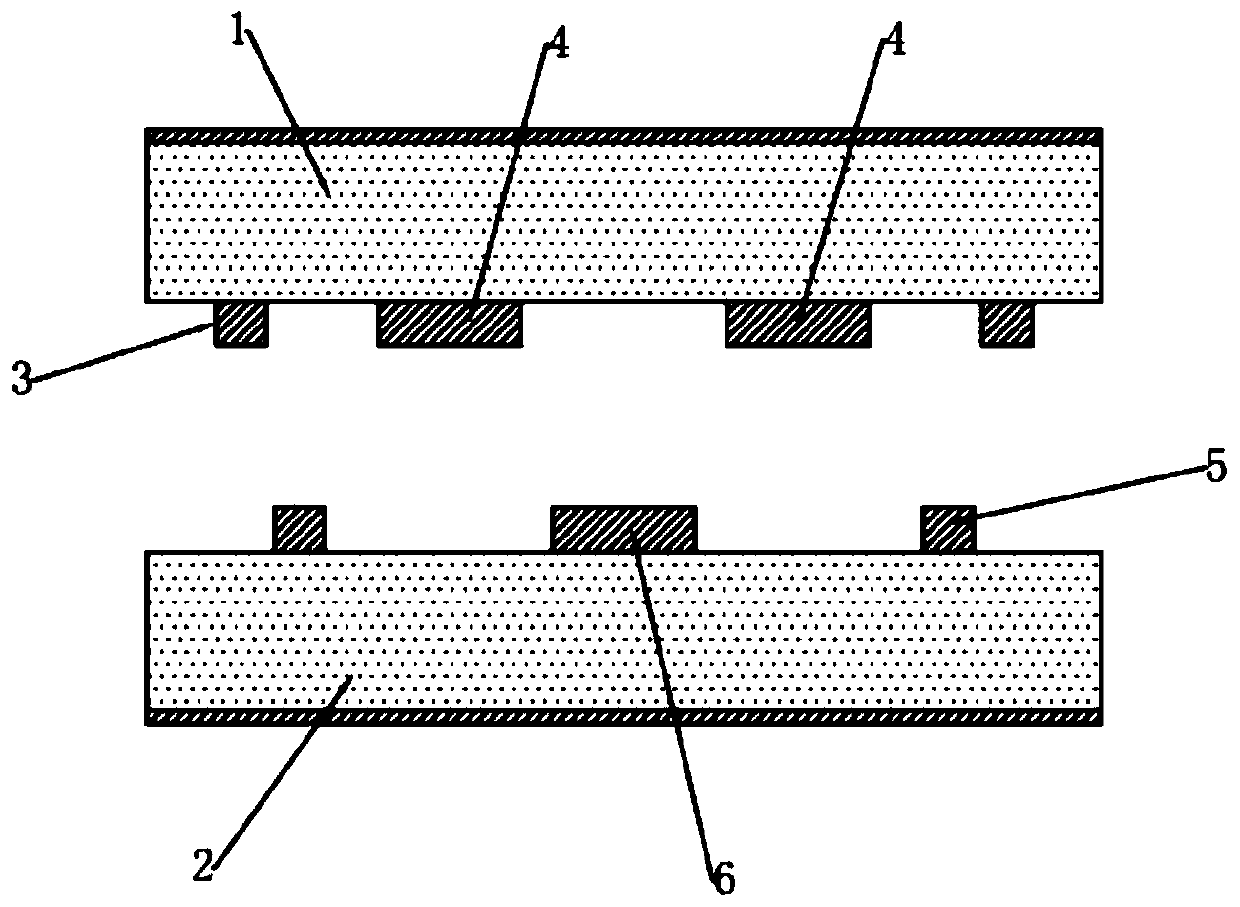

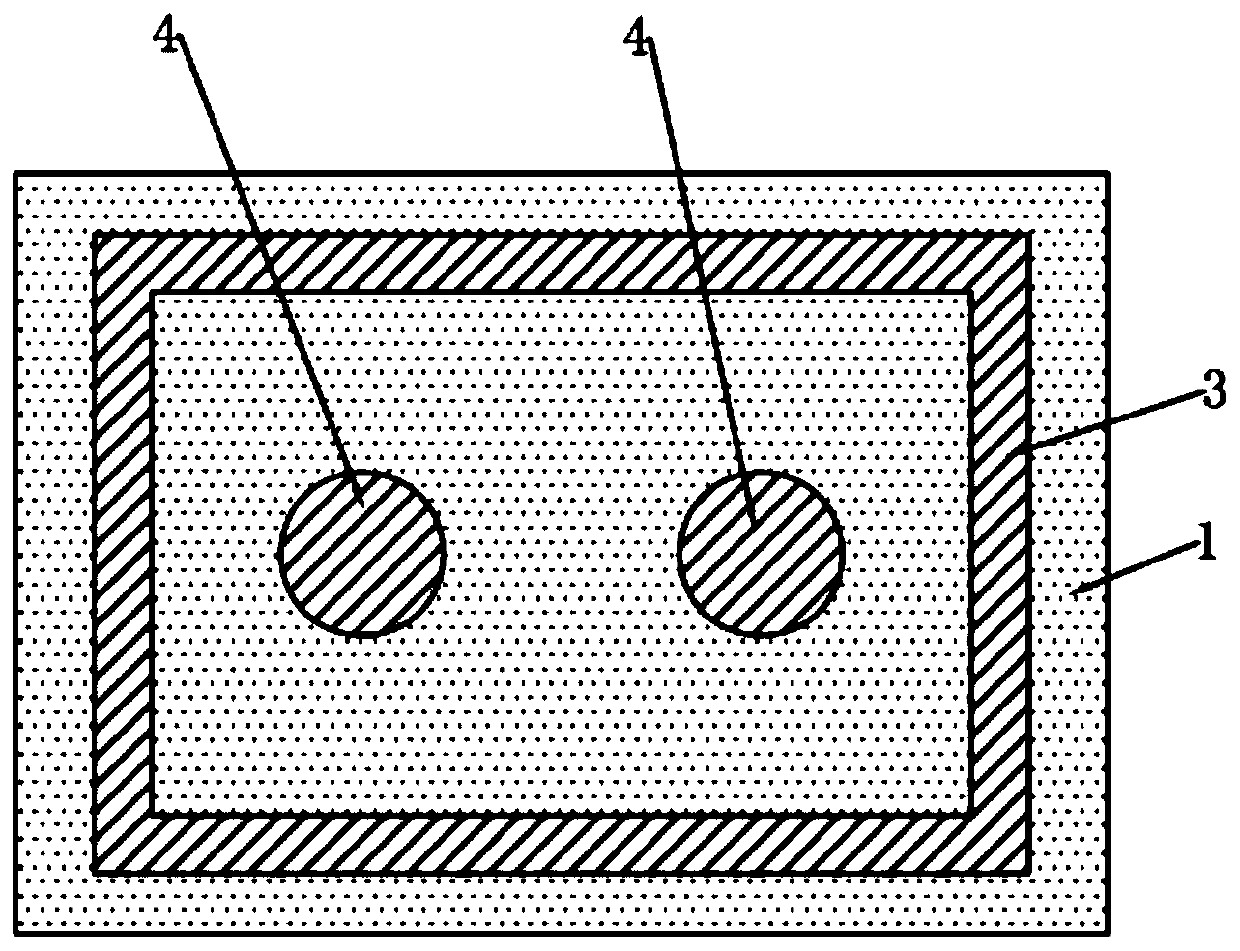

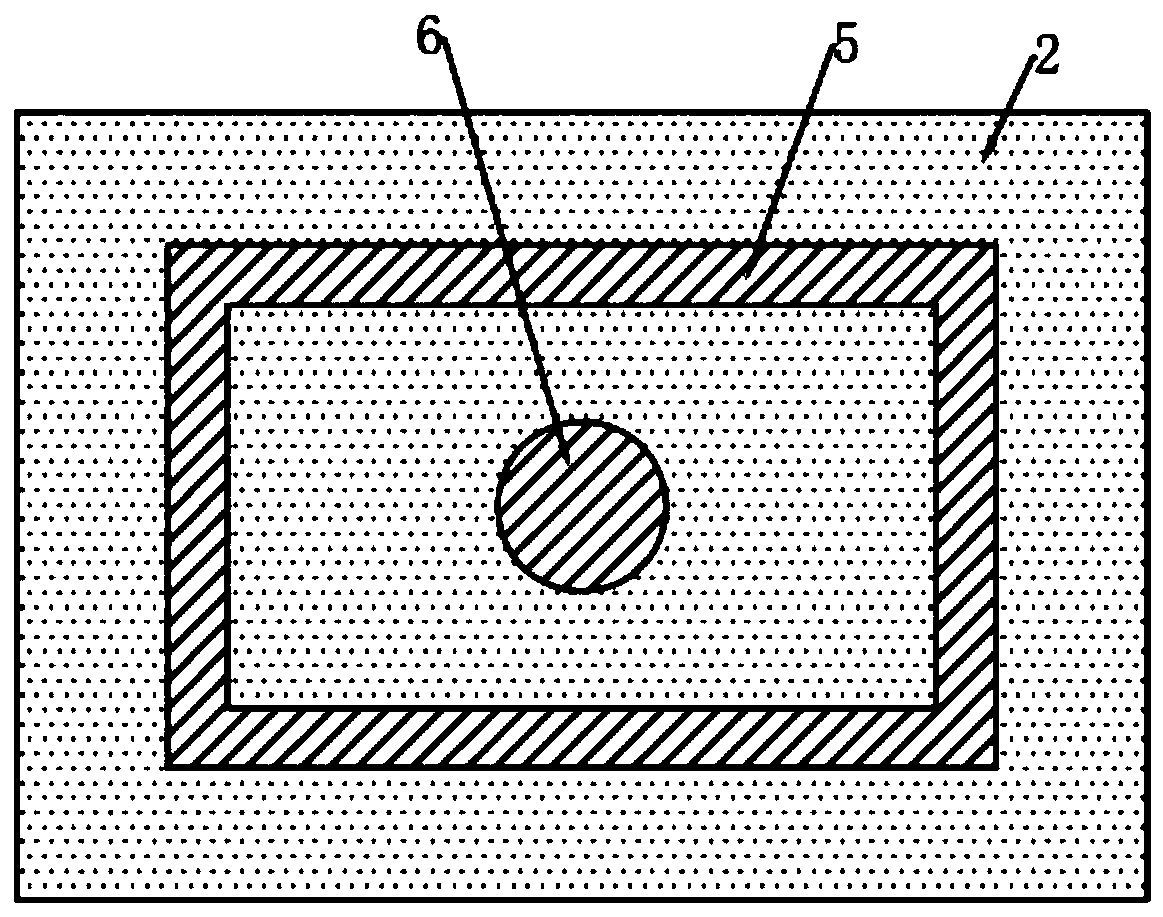

[0038] Referring to accompanying drawings 1-7, it is a method for manufacturing a single-input and double-outlet sound hole microphone substrate according to the present invention, comprising the following steps:

[0039] Step 1, prepare two asymmetrical copper thick core boards: the first core board 1 and the second core board 2, make the first copper ring 3 in the shape of "mouth" on the thick copper surface of the first core board and the first copper ring 3 on the first core board. Two first circular copper skins 4 are reserved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com