Intelligent dense shelf

A compact and intelligent technology, applied in the field of compact racks, can solve problems such as loss expansion, and achieve the effect of preventing the spread of fire and reducing fire losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

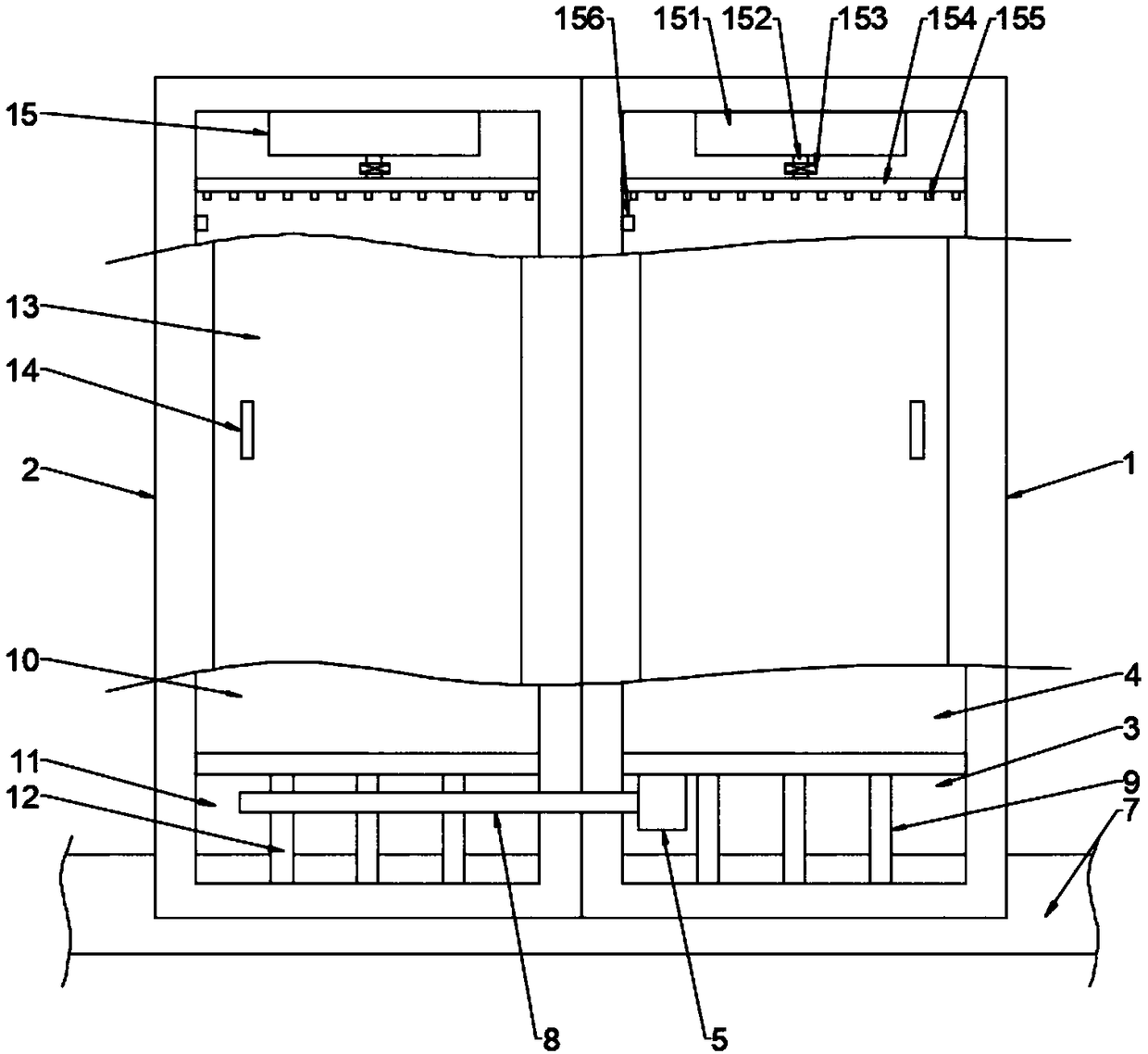

[0025] see Figure 1~3 , a kind of smart compact rack, comprising a main box 1 and a sub-box 2, the main box 1 is arranged on the right side of the sub-box 2, and the main box 1 is provided with a main separation chamber 3 and a main storage chamber 4 , the main separation chamber 3 is arranged below the main storage chamber 4, the auxiliary storage chamber 10 and the auxiliary separation chamber 11 are arranged in the auxiliary box body 1, and the auxiliary separation chamber 11 is arranged under the auxiliary storage chamber 10, The main separation chamber 3 is provided with a separation motor 5, and the motor shaft of the separation motor 5 is fixedly connected with a separation screw 8 matched with the auxiliary separation chamber 11, and the inner cavity of the main storage chamber 4 and the auxiliary storage chamber 10 The top of the side wall is provided with a smoke sensor 156, and the separation motor 5 is connected with all the smoke sensors 156 respectively. When a ...

Embodiment 2

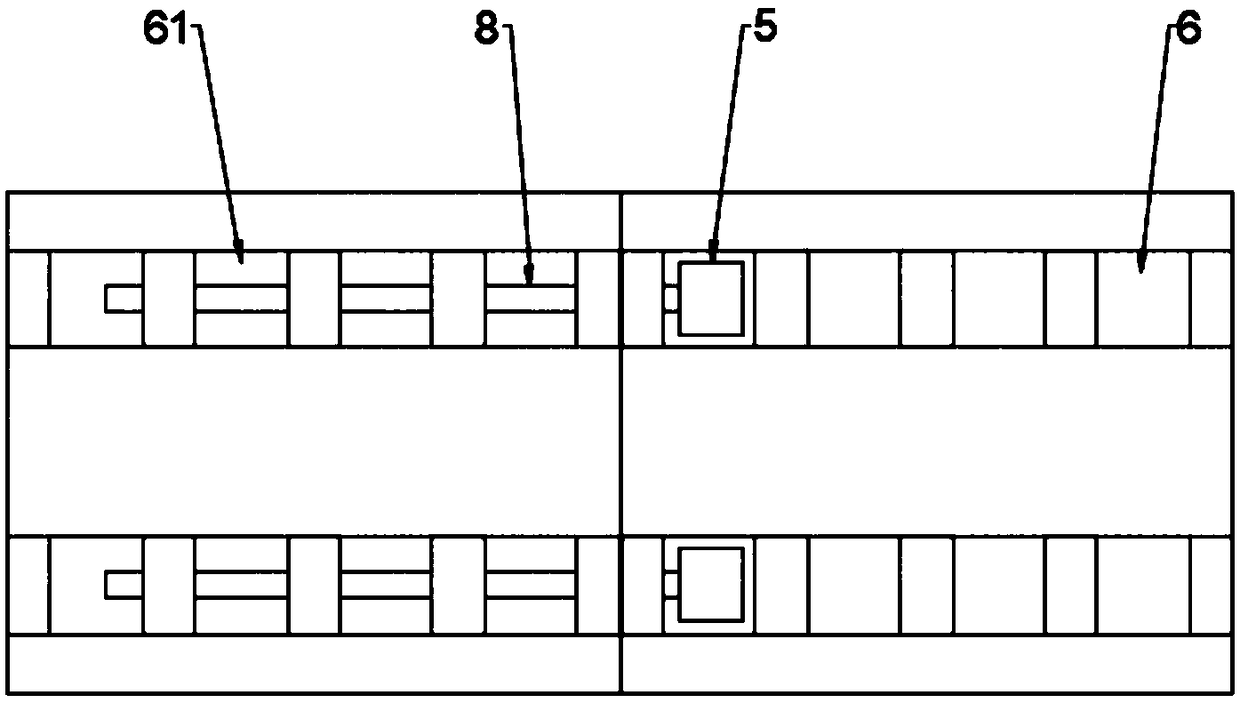

[0027] This embodiment is a further elaboration on the basis of Embodiment 1. The bottom end of the main box 1 is provided with a main chute 6 symmetrically front and rear, and the bottom end of the auxiliary box 2 is symmetrically provided with a main chute 6 front and rear. 6 matching auxiliary chute 61, the adjacent sides of the main chute 6 and the auxiliary chute 61 are all on the same straight line, the main chute 6 and the auxiliary chute 61 are jointly provided with slide rails 7, the main chute The box body 1 and the auxiliary box body 2 are all slidably connected to the ground through the slide rail 7, the main box body 1 and the auxiliary box body 2 can slide freely on the slide rail 7, and the movable space of the main box body 1 and the auxiliary box body 2 is improved. Convenience, thereby realizing the separation and bonding between the main box body 1 and the auxiliary box body 2, and the application is very convenient.

[0028] The main separation chamber 3 is...

Embodiment 3

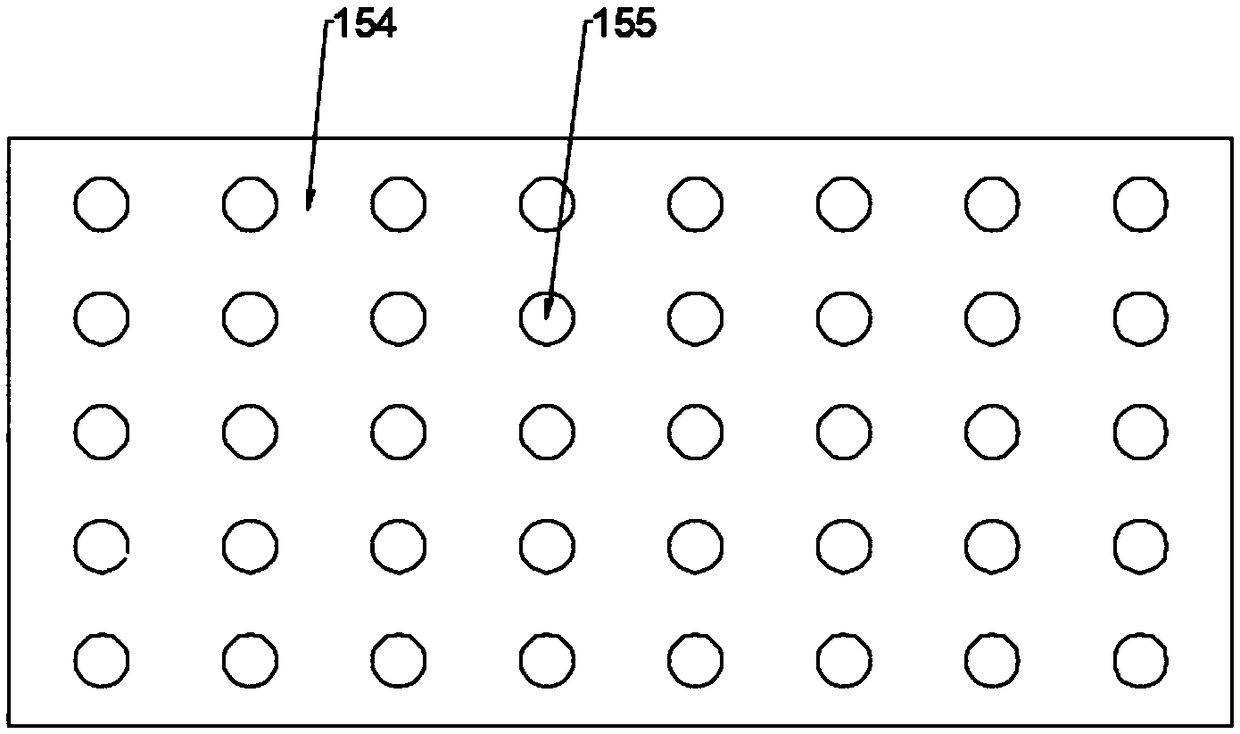

[0030] This embodiment is a further elaboration on the basis of Embodiment 1. The inner cavity top wall of the main storage chamber 4 and the auxiliary storage box 10 is provided with a fire extinguishing device 15, and the fire extinguishing device 15 includes a sand storage box 151 and a spraying tank. device 154, the spraying device 154 is located below the sand storage box 151, and the spraying device 154 is evenly provided with a number of nozzles 155, and the sand storage box 151 is connected to the spraying device 154 through the sand delivery pipe 152, and the sand delivery The pipe 152 is provided with a control valve 153, and the smoke sensor 156 in the same box is connected with the corresponding control valve 153. When a fire breaks out, the smoke sensor 156 senses fire information and transmits information to the control valve 153, and the control valve 153 is opened, the sand in the sand storage box 151 enters the spraying device 154 through the sand delivery pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com