Scribing machine

A scribing machine and machine technology, applied in manufacturing tools, workshop equipment, etc., can solve the problems of large error of 100-grid knife, large error of scribing line spacing, distortion of coating material performance evaluation results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

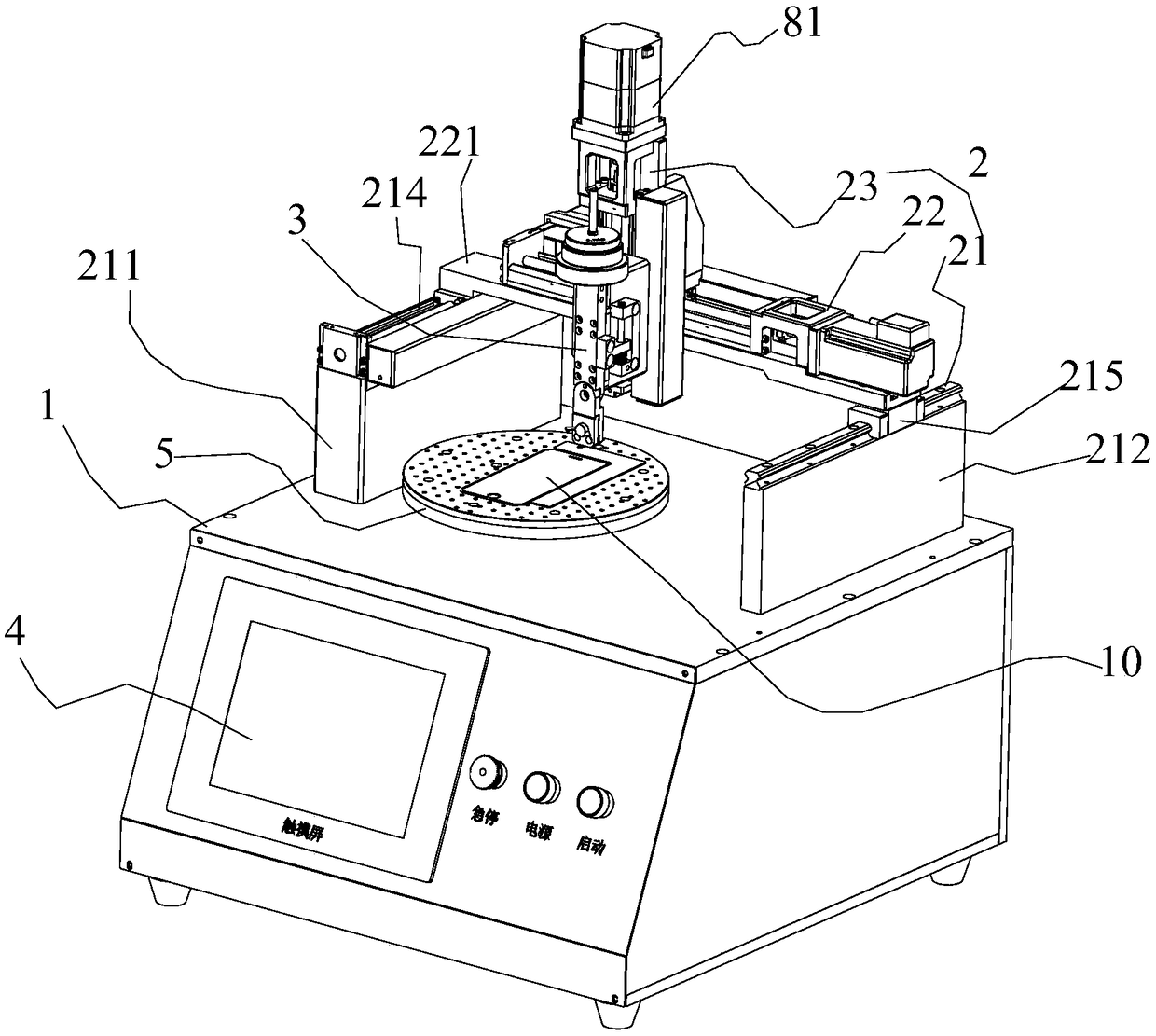

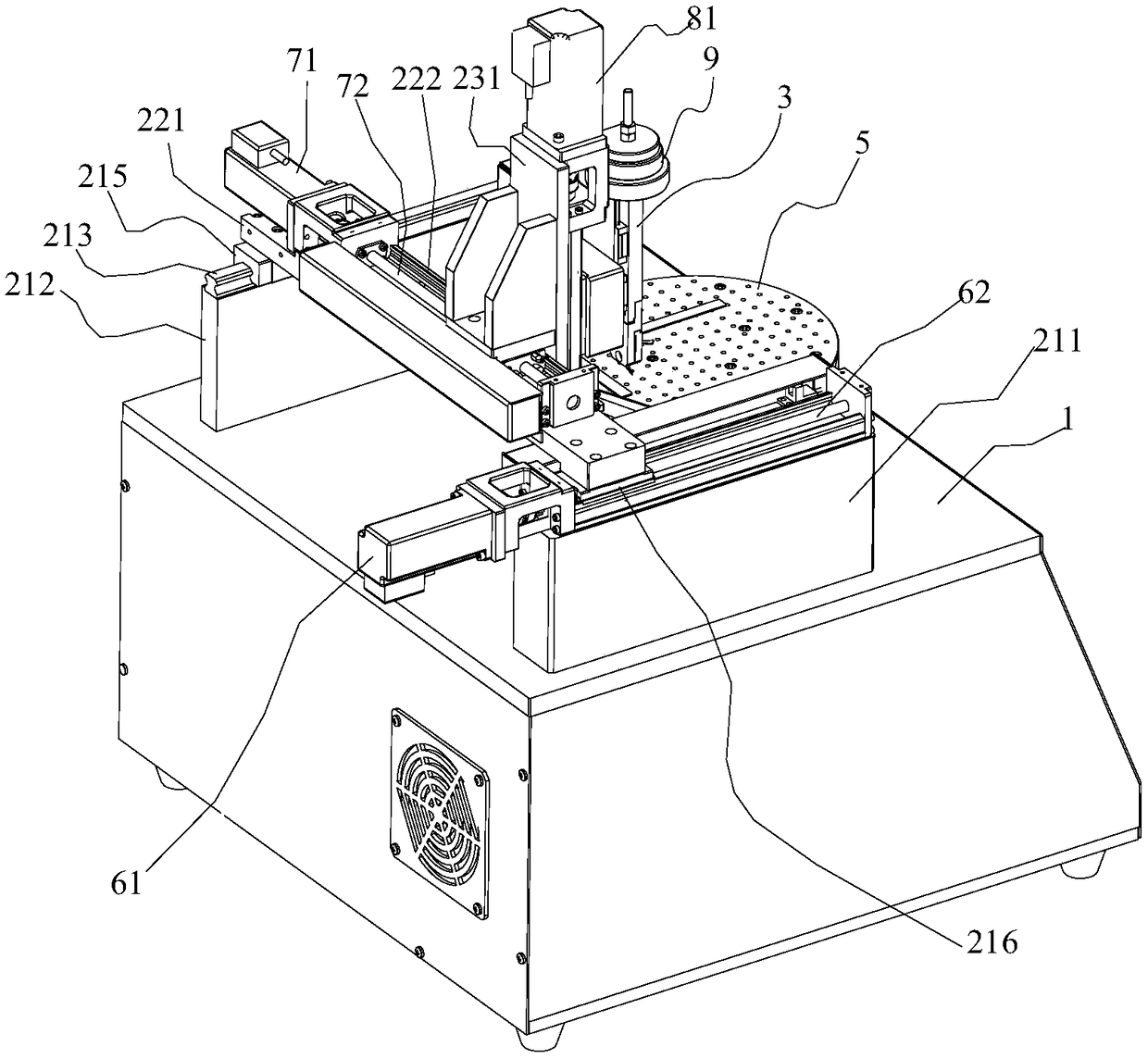

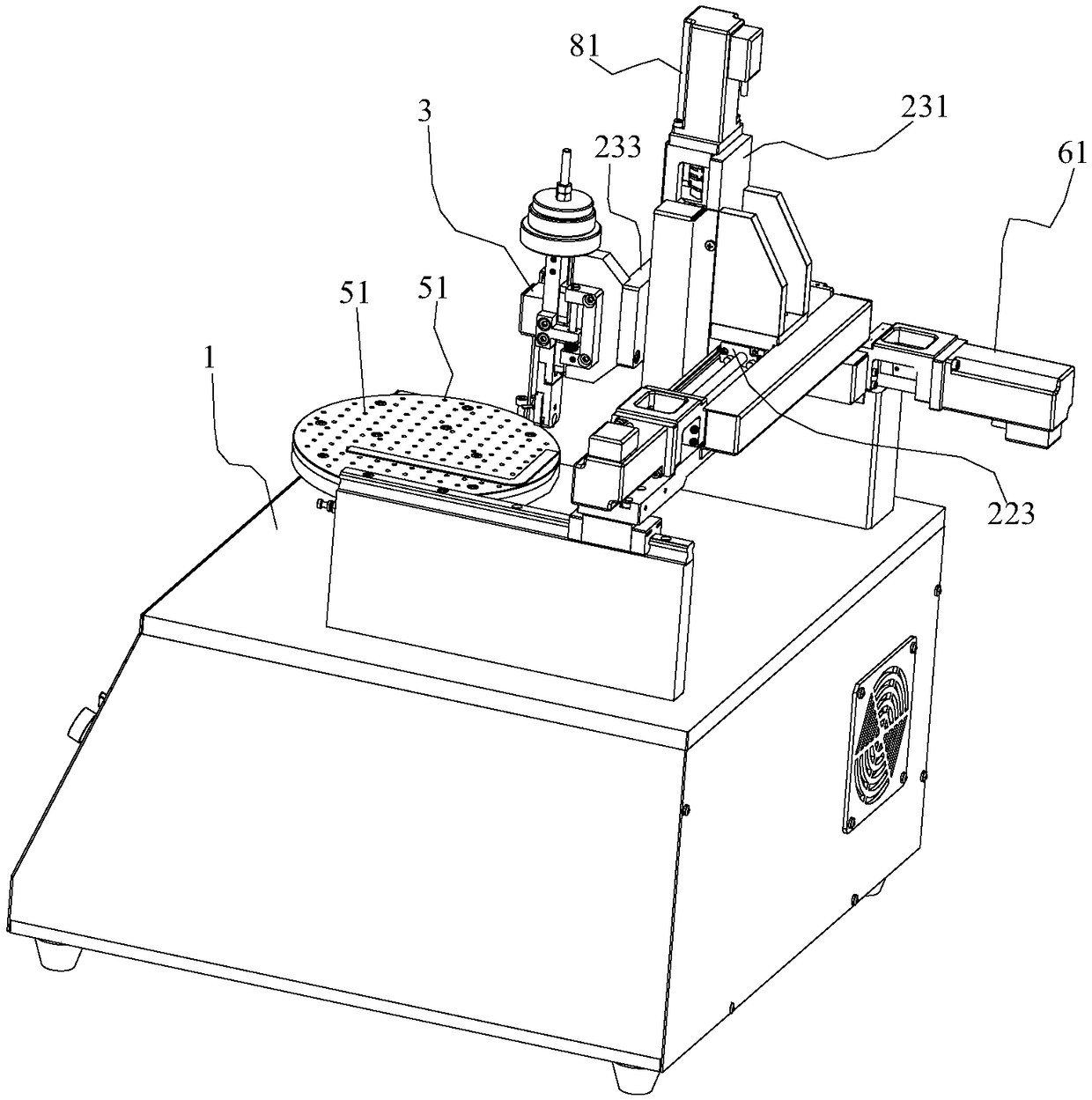

[0024] The scribing machine of the present invention, on the one hand, aims at errors such as the difference in depth of the scribing line caused by uneven artificial force applied to the traditional 100-grid cross-cut test device, and on the other hand, aims at the traditional 100-grid cross-cut test device. A solution is proposed for the low efficiency of scribing and the inability to realize fully automatic scribing; in order to facilitate the understanding of the technical solution of the present invention, the following will be described through examples and in conjunction with the accompanying drawings.

[0025] see figure 1 , figure 2 and image 3 , the marking machine of the present invention includes a machine platform 1, a knife displacement device 2 and a knife device 3, wherein the knife displacement device 2 is fixed on the surface of the machine platform 1, and the knife device 3 Installed at the scribe shifting device 2; a control device 4 and an object stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com