Manual module clamping jaw

A clamping jaw and module technology, applied in the field of clamping jaws, can solve the problems of large size of clamping jaw devices, prone to safety accidents, no self-locking mechanism, etc., and achieve the effects of simple structure, high safety and high safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

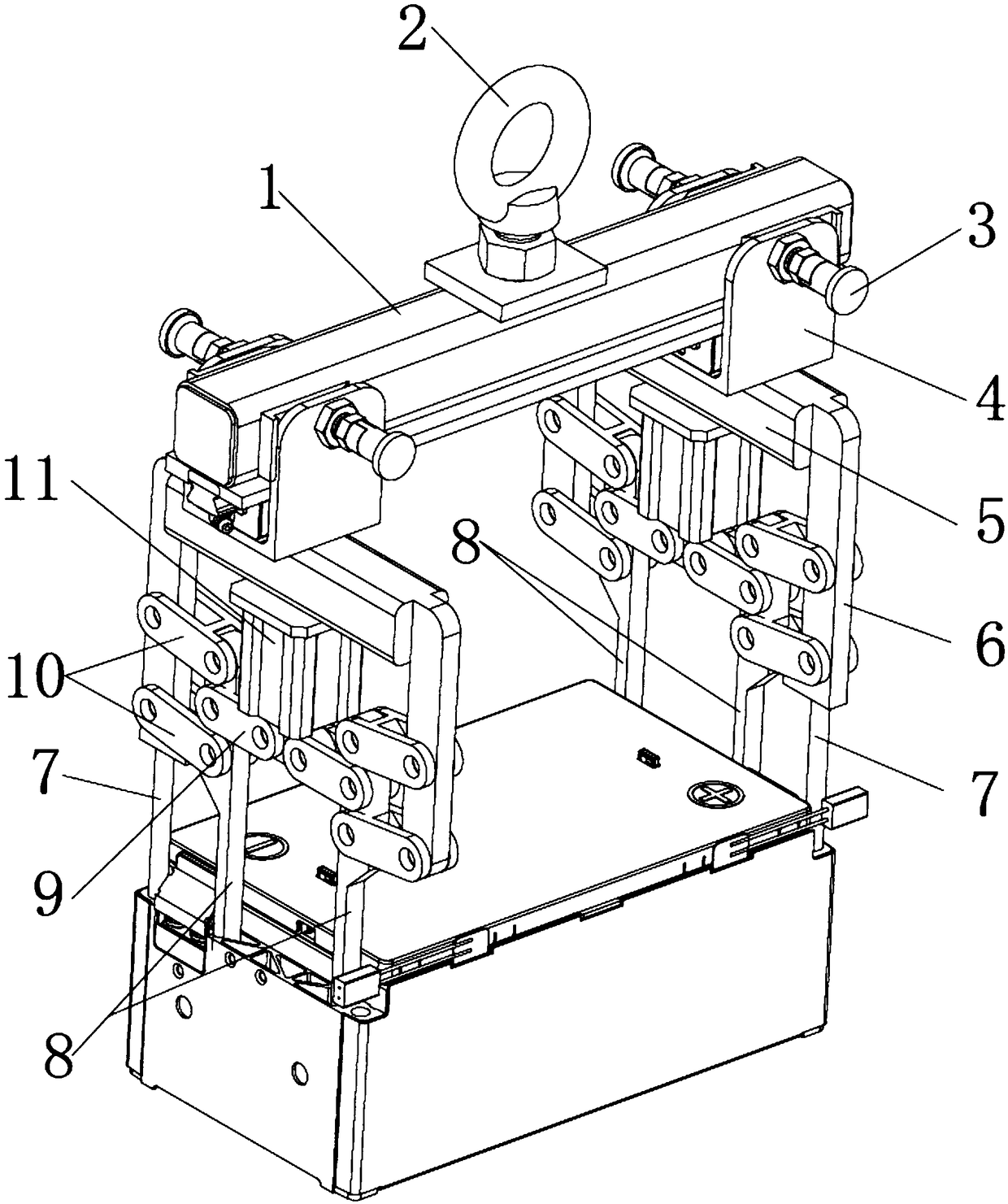

[0017] The positioning pin 7 positions the module. When the cylinder 11 shrinks, it drives the hinged two first connecting plates 9. There is a hinge shaft at both ends of each first connecting plate 9. The two first connecting plates 9 have four A hinged shaft, so that the four hinged shafts form a self-locking mechanism on the same line, and the two jaws 8 clamp the module under the action of the tension force of the self-locking mechanism; the two second connecting plates 10 are connected with the clamping mechanism. The hinged shaft of the claw 8 and the hinged shaft of the two second connecting plates 10 and the adjacent fixed plate 6 are arranged in a parallelogram structure. The two clamping jaws 8 are parallel, so that the surface contact between the module and the clamping jaw is realized, which greatly enhances the clamping force. Since the self-locking mechanism itself has a great self-locking property, it needs a lot of force to break it from the outside world, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com