Flow restrictor in micro-droplet jetting printing head

A technology of droplet jetting and jet printing, which is applied in the field of restrictors, can solve problems such as pressure loss in the pressure chamber and pressure crosstalk in the pressure chamber, and achieve the effect of reducing pressure loss, reducing pressure crosstalk, and being easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The purpose of the present invention is to construct a flow restrictor structure that is easy to process, and can effectively reduce the backflow of liquid in the pressure chamber and the pressure crosstalk between the pressure chambers, so as to improve the performance of the print head. The present invention will be described in detail below in conjunction with the accompanying drawings.

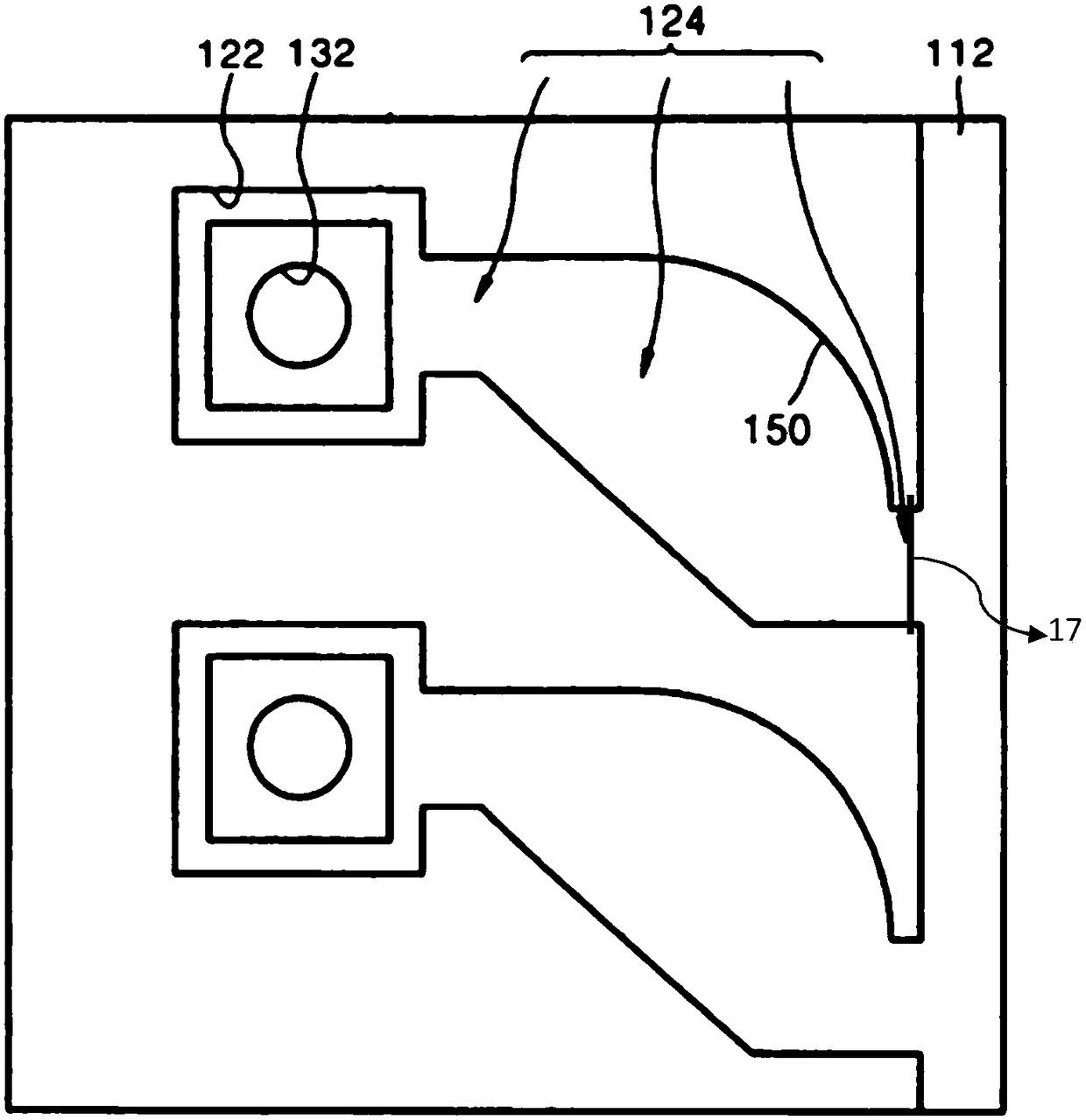

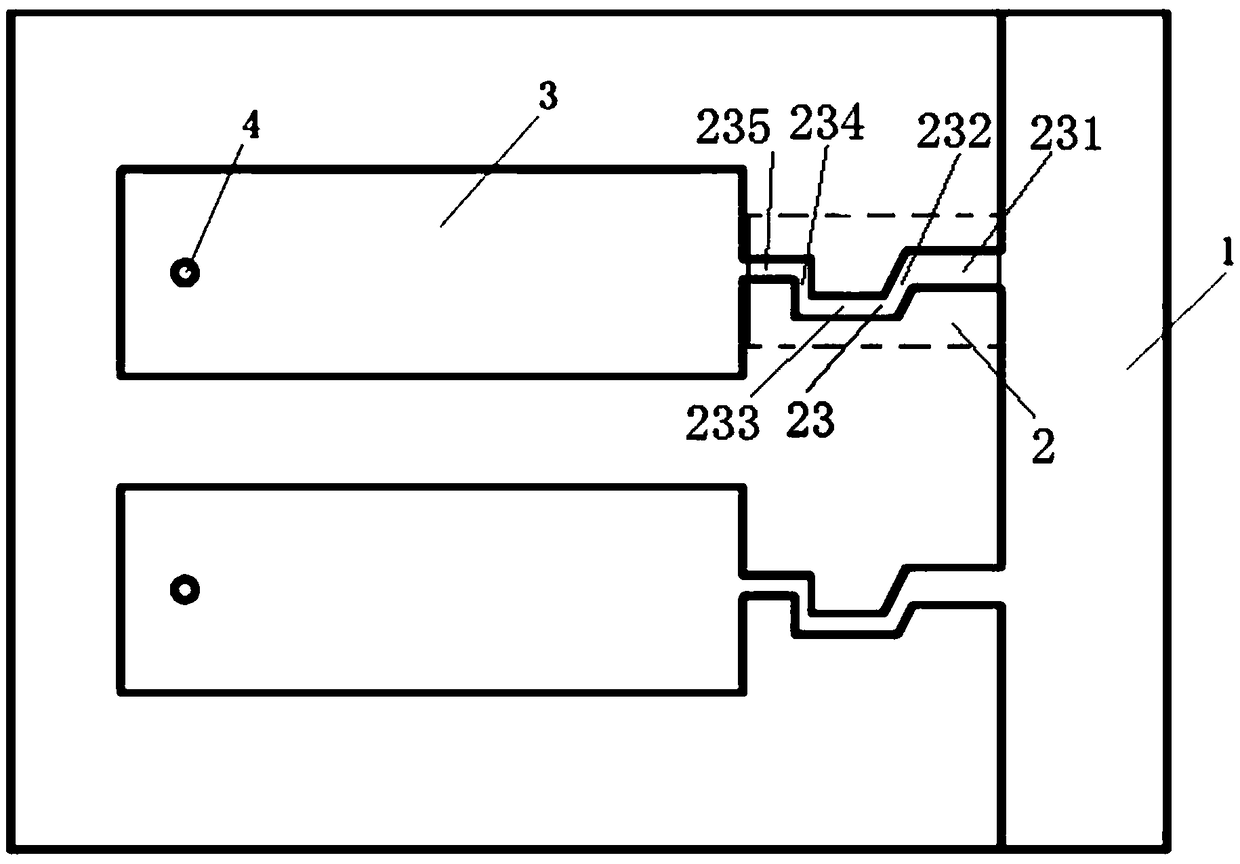

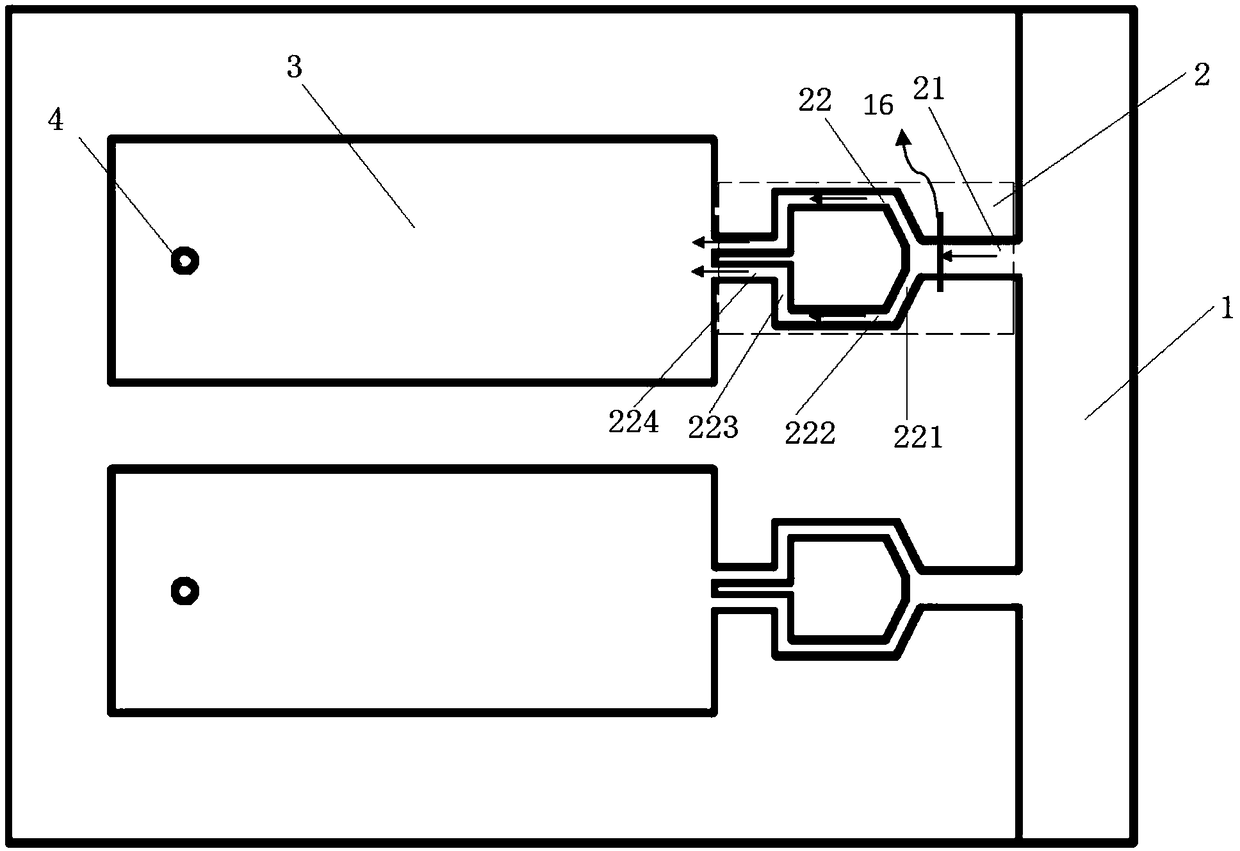

[0037] Such as Figure 2-3 As shown, the droplet jet printing head includes a main ink channel 1 , a flow restrictor 2 , an orifice 4 and a pressure chamber 3 . The main ink channel 1 is filled with the ink to be ejected; one end of the restrictor 2 is connected with the main ink channel 1 , and the other end is connected with the pressure chamber 3 . Pressure waves are generated in the pressure chamber 3 due to deformation and vibration of the piezoelectric body. The nozzle hole 4 is a droplet ejection outlet. When working, the ink flows from the main ink channel 1 through the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com