Self-powered sinking bottom net cage

A self-powered, bottom-sinking technology, applied in fish farming, application, climate change adaptation, etc., can solve problems such as the simple form of the multi-point mooring system, and achieve good wind and wave resistance, outstanding current resistance, and easy management Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

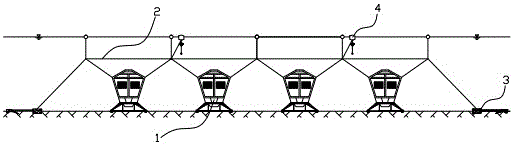

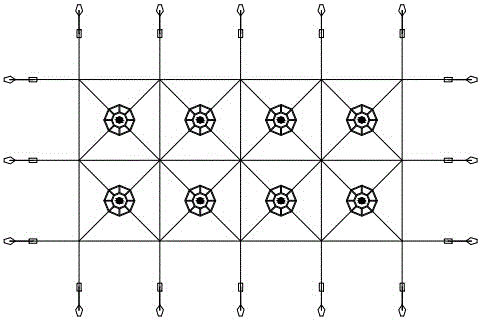

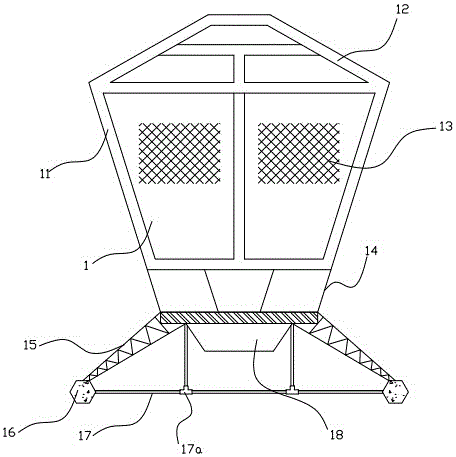

[0013] Example: refer to Figure 1 to Figure 4 , a self-powered sinking net cage, comprising a sinking net cage body 1 with a rigid main frame 11, wherein: the top of the main frame 11 is connected with a truss-shaped floating frame 12; the inner side of the sinking bottom net cage body 1 is connected with a closed net Garment 13; the lower side of the rigid main frame 11 is connected with a traction cable 14; the traction cable 14 is also connected with a self-sinking base with a retractable control assembly 18; the retractable control assembly 18 can retract the traction cable 14 as required to control the self-sinking base and The distance between the rigid main frame 11; the sinking bottom net box body 1 is connected with a transducer 4 that can convert wave energy into electric energy for retractable control assembly 18 and electricity storage. By retracting and retracting the control assembly 18, retracting the traction cable 14 to control the distance between the self-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com