Processing method and equipment of waste high polymer

A technology of high molecular polymer and processing equipment, applied in the direction of educts, products, reagents, etc., can solve problems such as impracticality, achieve good drainage, improve asphalt performance, and reduce low-temperature cracking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] The waste high molecular polymer is treated in the waste high molecular polymer liquefaction reactor.

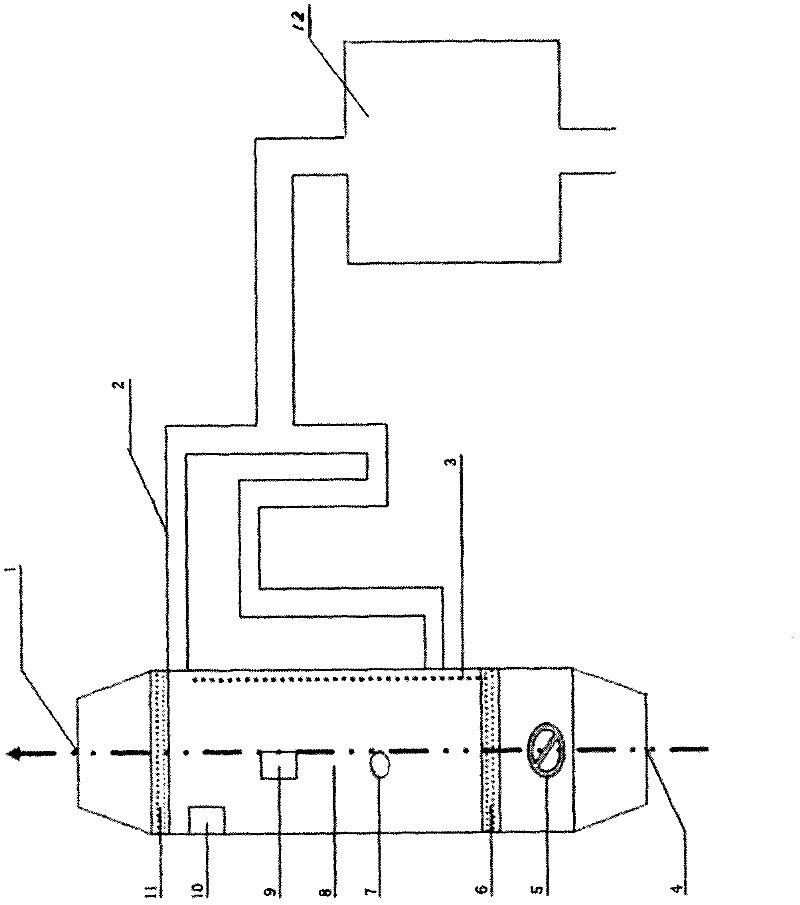

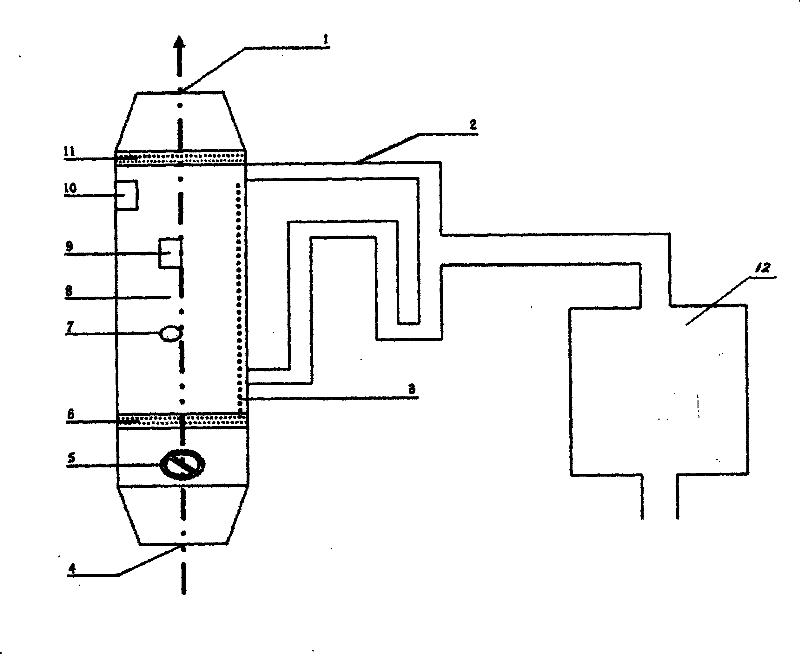

[0012] The structure of the reaction kettle is as follows: an asphalt inlet 1 is located at the top, an asphalt distribution plate (120 mesh screen) 11 is set at the inlet, a liquefaction furnace 8 is located in the middle of the kettle, a heating wire 3 is provided in the kettle, and a plastic asphalt outlet 4 is located at the bottom of the kettle , the top of the outlet is provided with a plastic asphalt distribution plate 6 (hole shape) and an agitator 5. The kettle body is provided with a thermometer 7, a peep hole 9 and a feeding hole 10, and the outside of the kettle body is connected with a pressure gauge 2 and a condenser 12, such as figure 1 shown.

[0013] Take 30 kg of asphalt and 10 kg of waste polymers (such as PE, PP, PVC, CR, NR and other polymers that are not cleaned or classified) and processed according to the following process:

[0014] Asphalt e...

Embodiment 2

[0016] Get 40 kilograms of bitumen waste polymer 10 kilograms, all the other are processed by the process of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com