Accidental injury prevention shield used for unmanned aerial vehicle

An unmanned aerial vehicle (UAV) and anti-error technology, applied in the field of UAV, can solve problems such as unfavorable stable flight of UAV, and achieve the effect of high safety, good intelligence and light equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

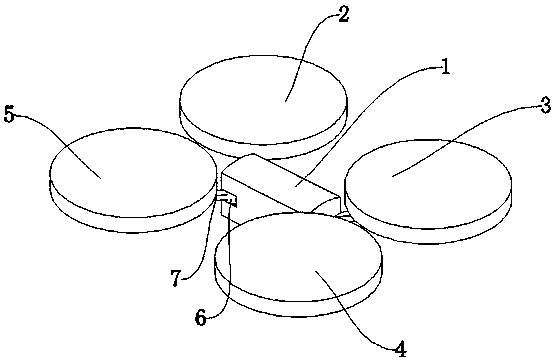

[0035] Such as Figure 1-Figure 6 As shown, an anti-accidental protective cover for drones includes a drone host 1, a first protective cover 2, a support rod 7, a wireless communicator 23, and a support rod 7 is arranged on one side of the drone host 1, and wireless communication The device 23 plays a communication role, and the supporting rod 7 plays a supporting role. A turning motor 6 is arranged between the UAV host 1 and the supporting bar 7. The turning motor 6 plays an adjustment role. The turning motor 6 is connected to the UAV host 1 by bolts. The UAV host 1 plays a load-bearing role, and the turning motor 6 is connected to the support rod 7 by screws. A fourth protective cover 5 is arranged on one side of the support rod 7. The fourth protective cover 5 plays a protective role, and the rear side of the fourth protective cover 5 is provided There is a first protective cover 2, the first protective cover 2 plays a protective role, and a second protective cover 3 is arr...

Embodiment 2

[0037] The difference between this embodiment and embodiment 1 is:

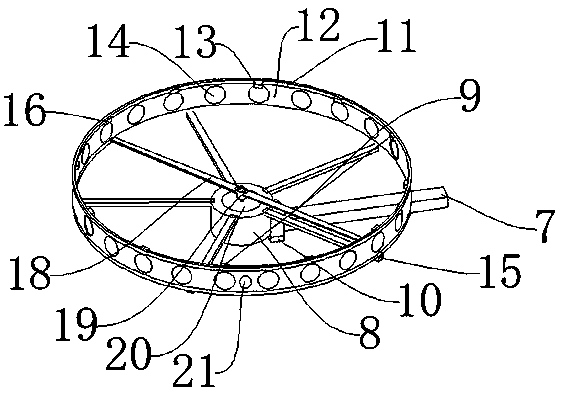

[0038]The inner side of the bottom support bar 15 is provided with a motor support 8, the motor support 8 is connected to the bottom support bar 15 by screws, a block 9 is provided on one side of the motor support 8, the block 9 and the motor support 8 are integrally formed, and the lower end of the block 9 is provided with Lock 10, block 9 is connected to lock 10 by buckle, bottom strut 15 plays a supporting role at the bottom, motor support 8 is connected with bottom support 15 by screw, guarantees the stability of motor support 8.

Embodiment 3

[0040] The difference between this embodiment and embodiment 1 is:

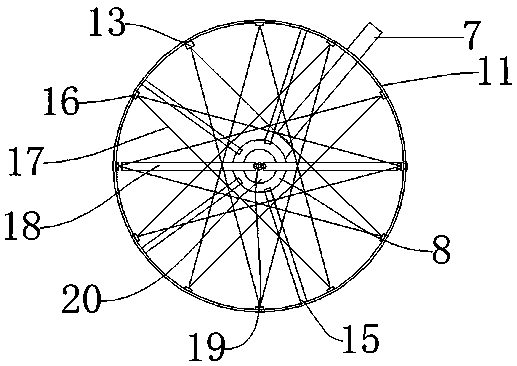

[0041] The inner side of the motor bracket 8 is provided with a helical motor 20, the helical motor 20 is connected to the motor bracket 8 by a buckle, the upper end of the helical motor 20 is provided with a fan blade bracket 19, the fan blade bracket 19 is connected to the helical motor 20 through a key, and the helical motor 20 is connected to the helical motor 20 through a card. Buckle is connected with motor support 8, has made things convenient for unmanned installation and dismounting.

[0042] Working principle: first use the block 9 to be stuck on the support rod 7, and then lock the lock 10. At this time, the bottom support rod 15 is stuck on the support rod 7, and then the screw motor 20, the blade bracket 19, the screw The fan blade 18 is installed, then the support ring 12 and the upper lock ring 11 are stuck on the bottom support bar 15 and the upper end protection net 17 is installed, and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com