Lifting device for building material transportation

A technology for buildings and adjustment boxes, applied in the direction of hoisting devices, clockwork mechanisms, etc., can solve problems such as affecting construction efficiency and reliability, limited use, inflexibility, etc., to achieve diversified improvement effects, stable transmission, The effect of improving conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

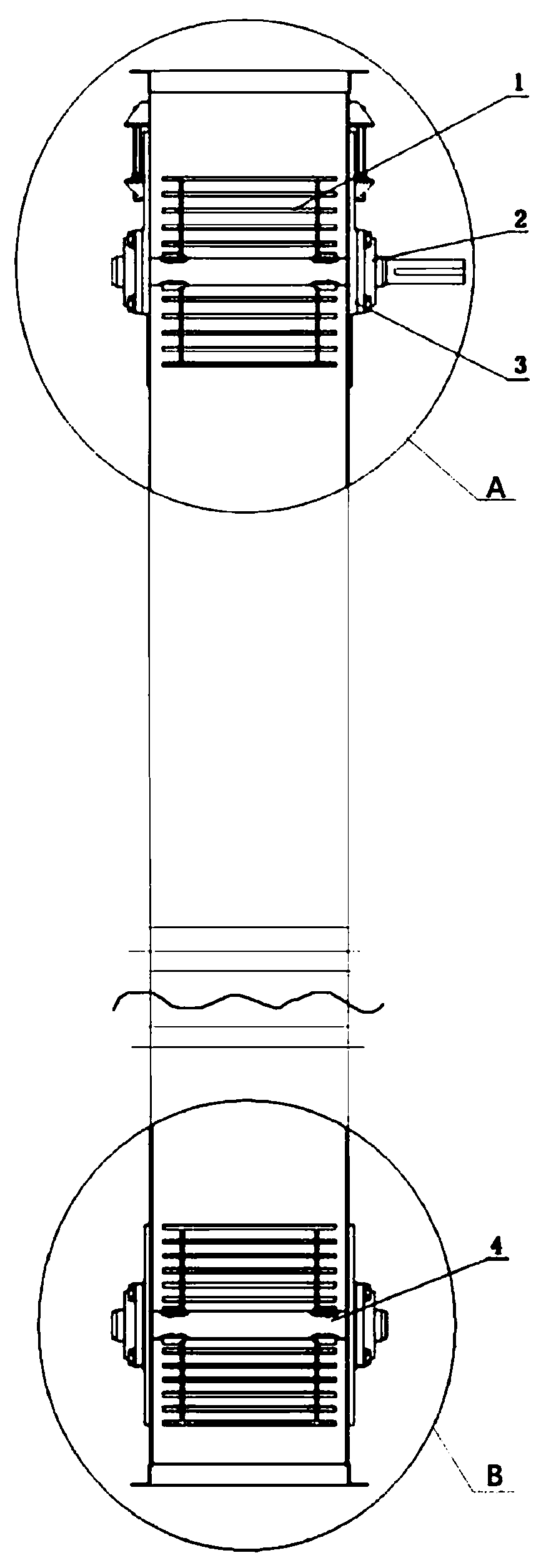

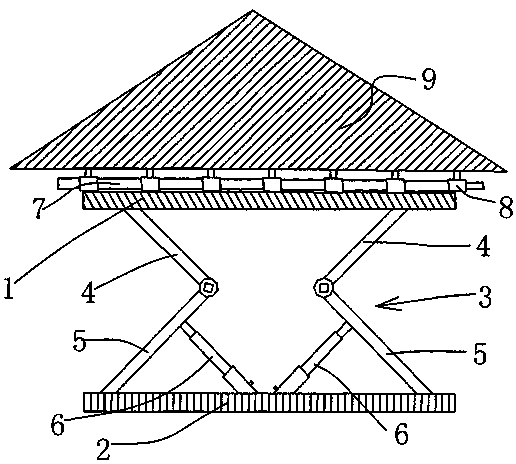

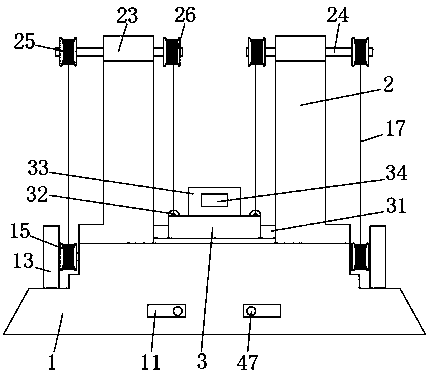

[0050] see Figure 3-7 , a lifting device for transporting building materials, comprising: a base 1, a support column 2, a fixing seat 3, and an adjustment box 4; both ends of the base 1 are provided with first grooves 11, and the first grooves One side of 11 is provided with limiting groove 12; One side of support column 2 is provided with second groove 27, and second groove 27 is provided with screw mandrel 21; Both ends of holder 3 are fixedly connected with transmission block 31, Both sides of the top of the fixing seat 3 are fixedly connected with fixing heads 32;

[0051] Both sides of the top of the base 1 are fixedly connected with a support block 13, one side of the support block 13 is provided with a first transmission shaft 14, one end of the first transmission shaft 14 is flexibly connected with the support block 13, and the other end of the first transmission shaft 14 One end is inserted into the first groove 11 and is fixedly connected with the first bevel gear ...

Embodiment 2

[0064] A lifting device for transporting building materials, comprising: a base 1 , a supporting column 2 , a fixing seat 3 , and an adjusting box 4 .

[0065] Both ends of the interior of the base 1 are provided with a first groove 11, one side of the first groove 11 is provided with a limiting groove 12, and both sides of the top of the base 1 are fixedly connected with a support block 13, one of the support blocks 13 The side is provided with a first transmission shaft 14, one end of the first transmission shaft 14 is flexibly connected with the support block 13, the other end of the first transmission shaft 14 is inserted into the first groove 11 and is fixedly connected with the first bevel gear 16, the first A first winding wheel 15 is fixedly connected to the outside of the middle part of the transmission shaft 14 .

[0066] One side of the support column 2 is provided with a second groove 27, the second groove 27 is provided with a screw rod 21, one end of the screw ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com