Bitter and refreshing type whole-wheat Pilsener beer malt formula, obtained beer and making method thereof

A bitter and refreshing malt technology, applied in the field of beer, to achieve the effect of good coordination of bitterness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

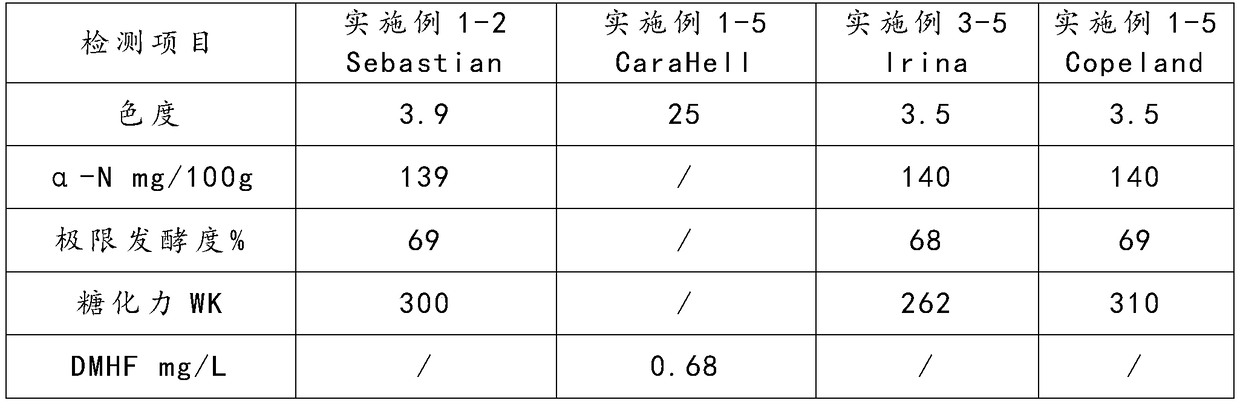

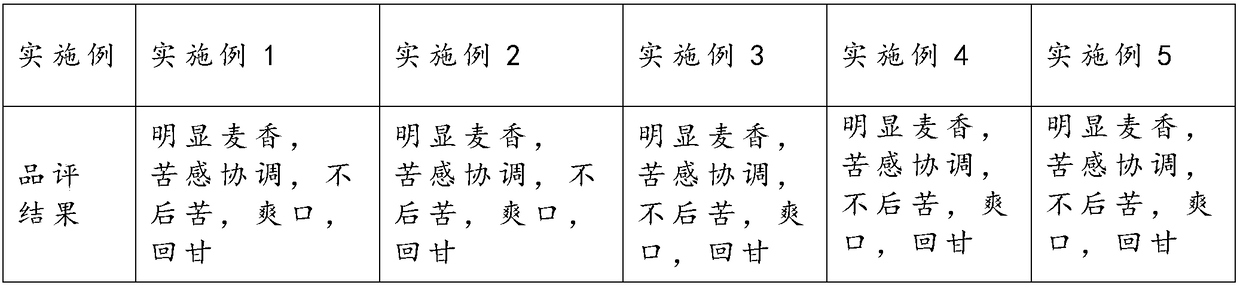

Embodiment 1

[0039] Barley malt (French Malt Sebastian Peel Malt 30%-49%, French Malt Quench Pearson Malt 25%-30%, Added Malt Copeland Pearson Malt 25%-30%, Light Color Caramel Malt CaraHell 1%-10% ), water as the main raw material, through crushing→saccharification→filtering→boiling (hops Hallertauer Tradition 36%, Hersbrucker 64%)→gyroscope precipitation→cooling→oxygenation→adding the following yeast→fermentation→filtration→sterilization→that is, 10.5°P bitter Refreshing whole wheat pilsner beer.

Embodiment 2

[0041] Barley malt (French Malt Sebastian Peel Malt 30%-49%, French Malt Quench Pearson Malt 25%-30%, Added Malt Copeland Pearson Malt 25%-30%, Light Color Caramel Malt CaraHell 1%-10% ), water as the main raw material, through crushing→saccharification→filtering→boiling (hops Hallertauer Tradition 100%)→gyroscope precipitation→cooling→oxygenation→adding the following yeast→fermentation→filtering→sterilization→that is, 10.5°P bitter and refreshing full-bodied Pilsner beer.

Embodiment 3

[0043] Barley malt (French malt Irina Peel malt 65%-69%, Gamalt Copeland Pearson malt 25%-30%, light-colored caramel malt CaraHell 1%-10%) and water are the main raw materials, which are crushed→saccharified→ Filtration→boiling (hops Hallertauer Tradition 36%, Hersbrucker 64%)→gyroscope precipitation→cooling→oxygenation→adding the following yeast→fermentation→filtering→sterilization→obtain 10.5°P bitter and refreshing whole wheat Pilsner beer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com