Bitter-refreshing whole wheat Pilsener beer and preparation method thereof

A bitter and refreshing beer technology, applied in the field of beer, to achieve the effect of bitter taste, sweet taste and good coordination of bitterness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

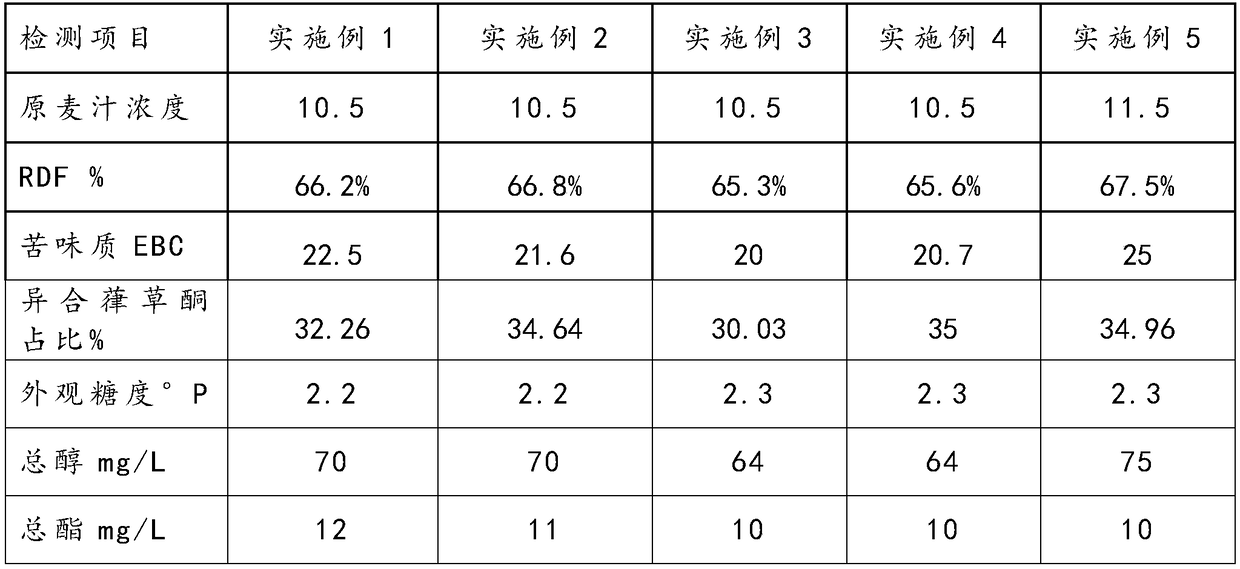

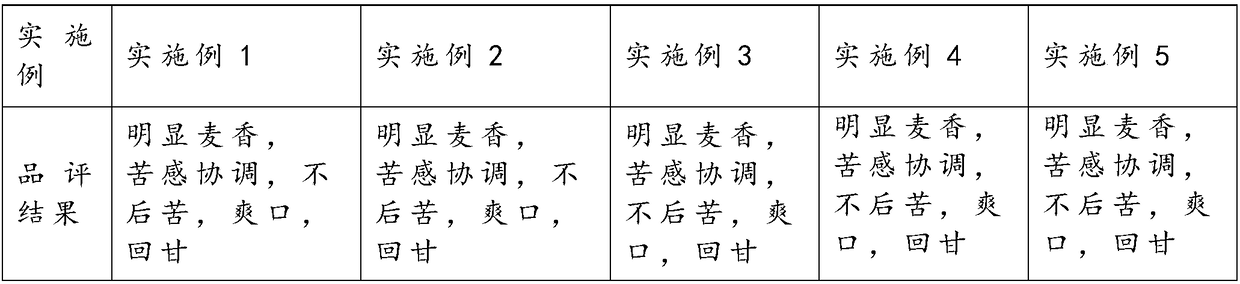

Examples

preparation example Construction

[0027] The embodiment of the present invention also provides a method for preparing the bitter and refreshing whole wheat Pilsner beer according to the above embodiment, comprising the following steps:

[0028] S1: Pilsner malt, light-colored caramel malt and water are selected as the main raw materials, mixed with a material-to-water ratio of 1:3-1:4, and two-stage saccharification is carried out at 62-72°C.

[0029] In this step, when the malt is mixed with water, the requirements for the feeding time of the malt are different, that is, the dry crushed malt is fed at 50-55°C, and the wet crushed malt is fed at 62-65°C, so as to ensure the malt after crushing. Take advantage of. In addition, in this step, the saccharification process is optimized as a two-stage saccharification, which can not only ensure the decomposition of starch, but also facilitate the control of the limit fermentation degree of wort.

[0030] S2: After saccharification, filter the saccharification mash ...

Embodiment 1

[0040] Barley malt (French Malt Sebastian Peel Malt 30%-49%, French Malt Quench Pearson Malt 25%-30%, Added Malt Copeland Pearson Malt 25%-30%, Light Color Caramel Malt CaraHell 1%-10% ), water as the main raw material, through crushing→saccharification→filtering→boiling (hops Hallertauer Tradition 36%, Hersbrucker 64%)→gyroscope precipitation→cooling→oxygenation→adding the following yeast→fermentation→filtration→sterilization→that is, 10.5°P bitter A refreshing whole wheat pilsner.

Embodiment 2

[0042] Barley malt (French Malt Sebastian Peel Malt 30%-49%, French Malt Quench Pearson Malt 25%-30%, Added Malt Copeland Pearson Malt 25%-30%, Light Color Caramel Malt CaraHell 1%-10% ), water as the main raw material, through crushing→saccharification→filtering→boiling (hops Hallertauer Tradition 100%)→gyroscope precipitation→cooling→oxygenation→adding the following yeast→fermentation→filtering→sterilization→that is, 10.5°P bitter and refreshing full-bodied Pilsner beer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com