Assistant guiding device for fabric feeding of sewing machine

A technology of guiding device and sewing machine, applied in the direction of sewing machine components, sewing equipment, cloth feeding mechanism, etc., can solve the problems such as offset or meandering of cutting knife cutting position, poor completion condition, and poor appearance, etc., to reduce defects and stabilize The effect of reducing resistance and reducing working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Embodiments of the present invention will be described below based on the drawings.

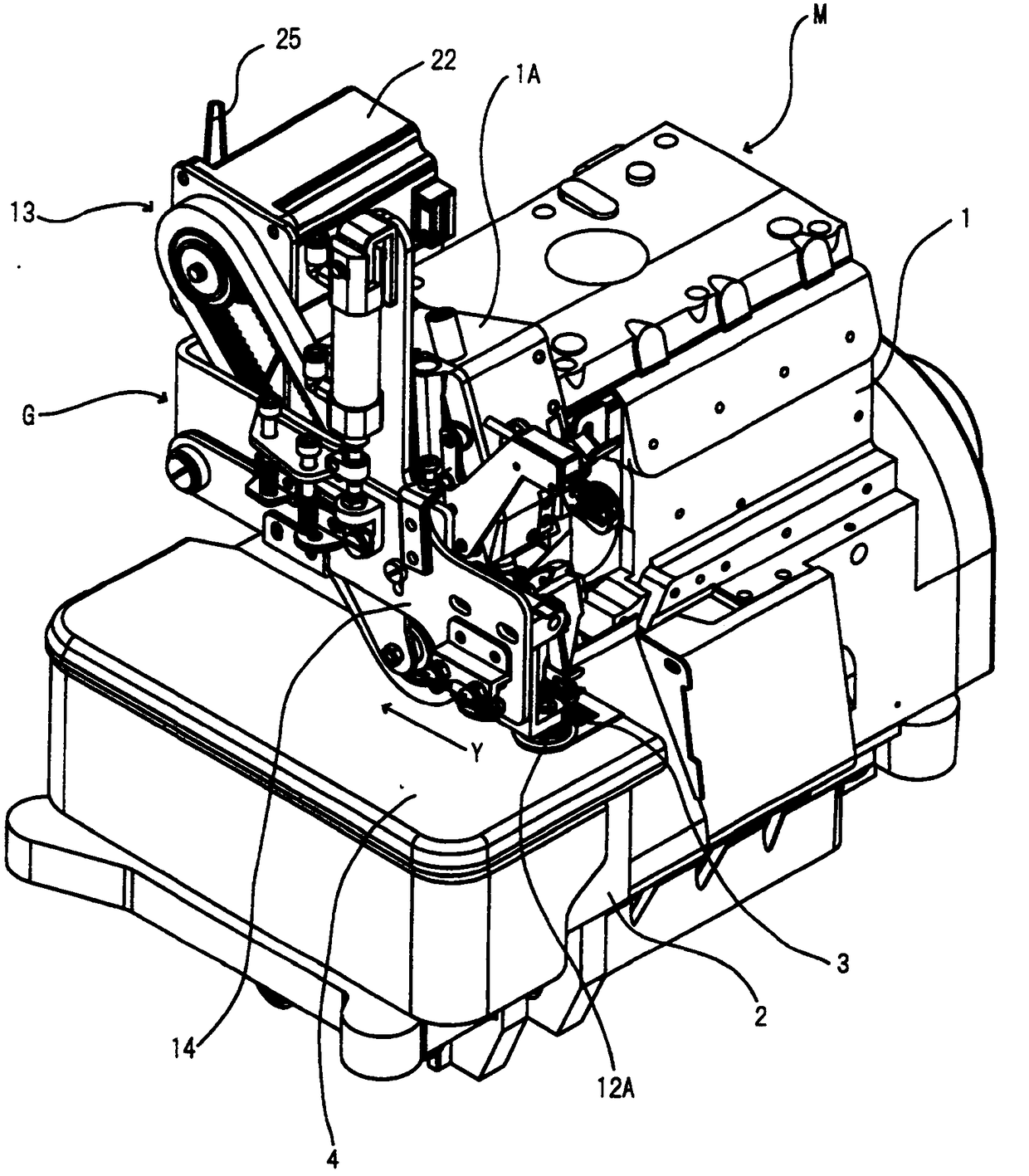

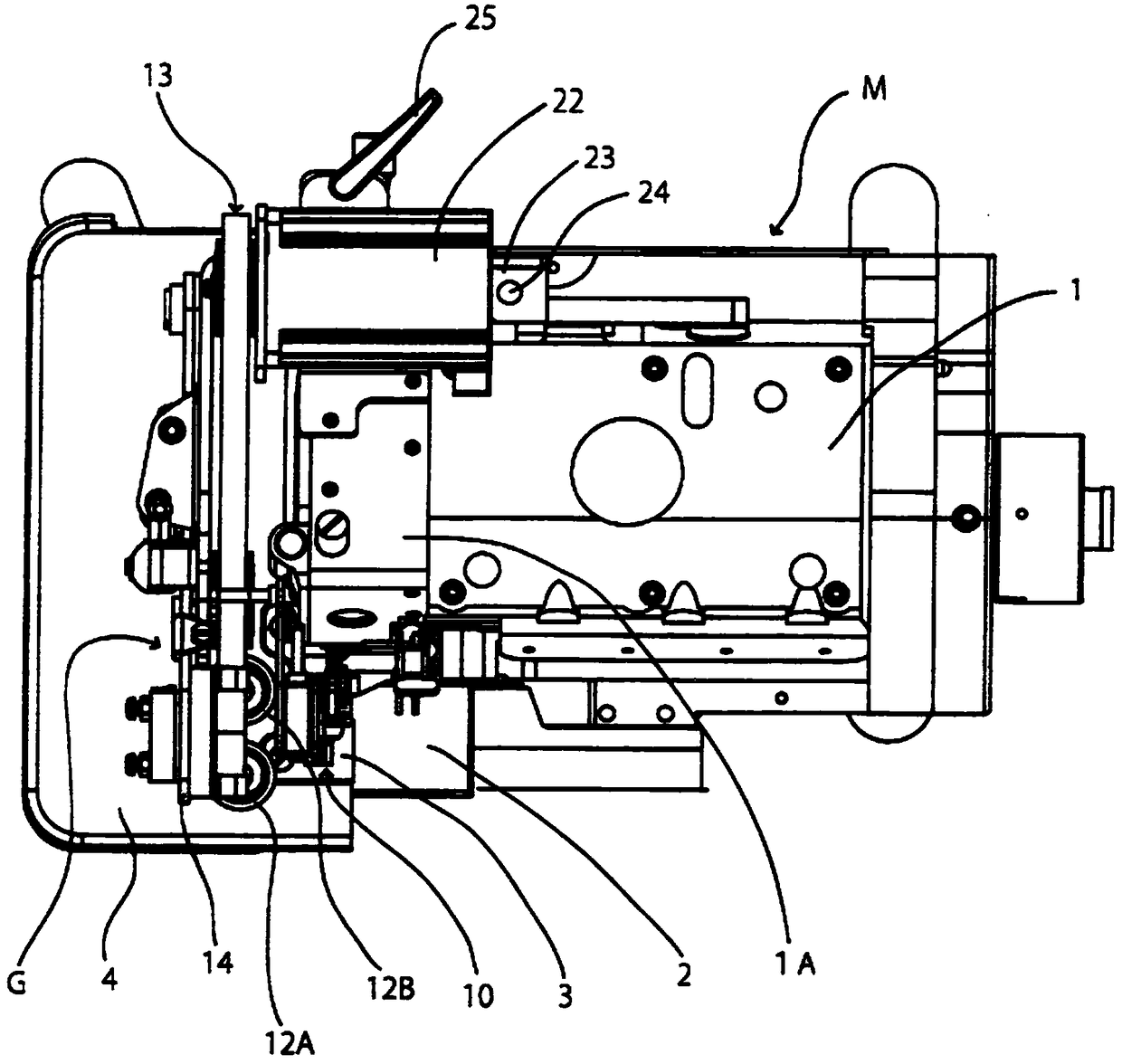

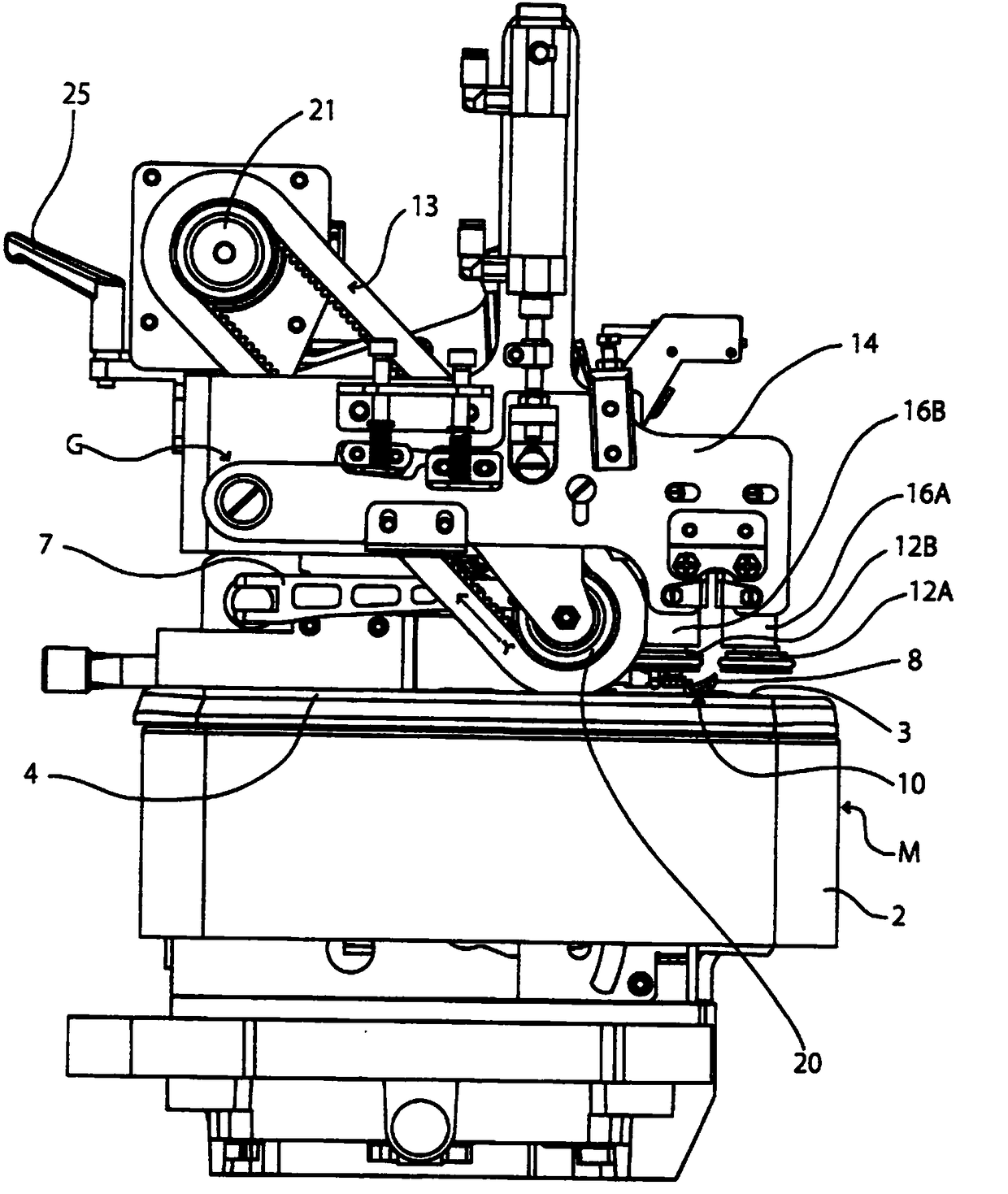

[0050] figure 1 It is an overall perspective view of a double-needle overlock sewing machine according to an embodiment of the present invention and a material feeding auxiliary guide device installed in a sewing machine main body of the overlock sewing machine, figure 2 and image 3 It is the overall top view and the overall left side view of the sewing machine and the auxiliary material feeding guide device, Figure 4 is an enlarged perspective view of the main part of the sewing machine and the material feeding auxiliary guide device, Figure 5 is an enlarged longitudinal sectional front view of the main part of the sewing machine and the material feeding auxiliary guide device, Figure 6 It is an enlarged cross-sectional top view of the main part of the fabric feeding auxiliary guiding device.

[0051] The above-mentioned double-needle overlock sewing machine M includes a sew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com