Tubular pile body butt joint construction method

A construction method and technology of pipe piles, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of complicated docking work and low efficiency of pipe piles, and achieve reduced hovering time, high docking accuracy, The effect of reducing the working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further illustrated below by specific examples.

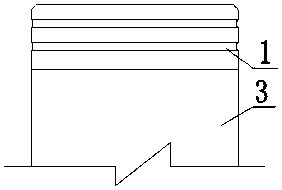

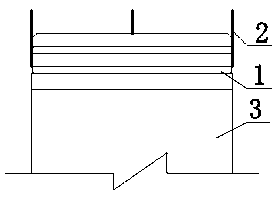

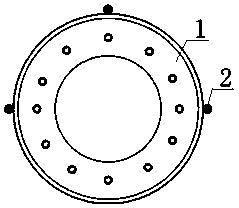

[0018] like Figure 1~Figure 4 As shown, a pipe pile pile body butt joint construction method includes assembly tooling, and the tooling includes a collar 1 and a limit rod 2; wherein, the collar 1 is a band-shaped closed ring structure, and the outside of the collar 1 is connected to the limit rod The rods 2 are connected by welding, and each ferrule 1 needs to be equipped with three limit rods 2. The length of the ferrule 1 is 150 mm, and the thickness is 1.5-2 mm. One end is welded to ferrule 1, the end of limit rod 2 welded to ferrule 1 is equal to the length of the unwelded end, three limit rods 2 are evenly distributed on the outer wall of one ferrule 1 at 180 degrees, limit rod 2 and Ferrules (1) are kept parallel at all times; the following steps are also included:

[0019] Step 1. Make pairing tooling:

[0020] After the construction of the first section of pipe pile 3.1 is completed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com