Helicopter tower positioning device

A technology for positioning devices and helicopters, applied to towers, building types, buildings, etc., can solve time-consuming problems and achieve the effect of reducing hovering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

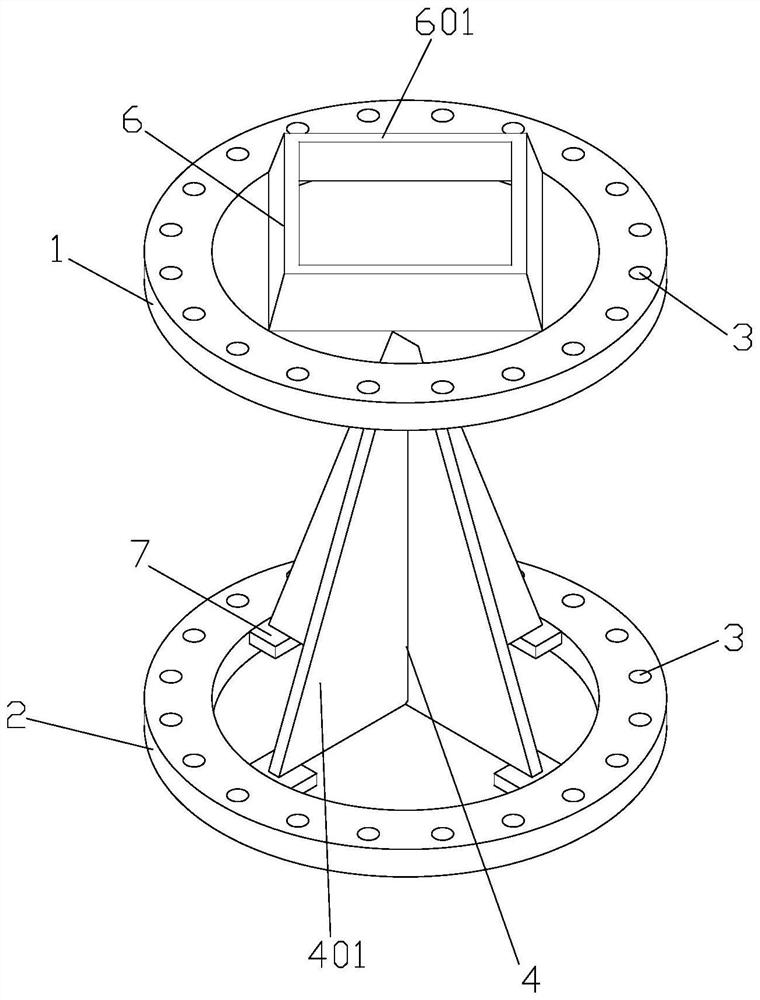

[0029] A helicopter vertical tower positioning device, comprising a main plate 2, a secondary plate 1, a guide plate 601 and a right-angle plate 401. In this embodiment, two ring-shaped cake-shaped flat plates are selected as the main plate 2 and the secondary plate 1, because currently In the process of manufacturing the iron tower, a circular cake-shaped flat plate is welded on the outer wall of the steel pipe, so in consideration of versatility, both the main plate 2 and the auxiliary plate 1 use a circular pie-shaped flat plate; the four right-angle plates 401 are combined Welded on the protruding plate 601 of the main plate to form a cross-shaped quadrangular pyramid-shaped protruding positioning structure 4, four right-angled plates 401 are selected in this embodiment, and more right-angled plates 401 can also be selected for welding and splicing in other embodiments Protruding positioning structure 4; four guide plates 601 and auxiliary disc 1 are welded together to form...

Embodiment 2

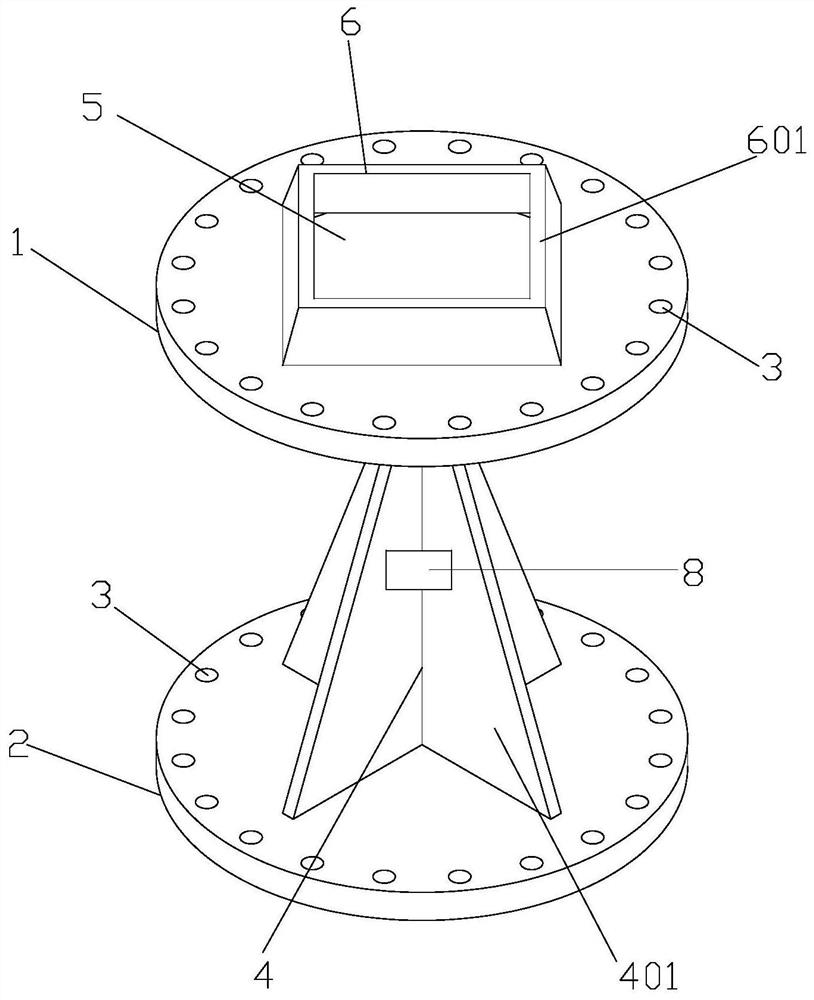

[0031] A helicopter tower positioning device, comprising a main plate 2, an auxiliary plate 1, a guide plate 601, a right-angle plate 401 and a stabilizing plate 8, in this embodiment, the main plate 2 and the auxiliary plate 1 are solid discs, and the auxiliary plate 1 is provided with a There are positioning holes 5, and four guide plates 601 are welded together with the auxiliary disk 1 to form a guide sleeve 6. The guide sleeve 6 is in the shape of a four-sided frustum with two ends open, and the wide mouth end of the guide sleeve 6 is in the position of the positioning hole 5. On the edge of the hole; four right-angle plates 401 are assembled and welded on the main plate 2 to form a cross-shaped quadrangular pyramid-shaped positioning protrusion structure 4, and the two ends of the stabilizing plate 8 are respectively welded on two adjacent right-angle plates 401. In this embodiment, four guide plates 601 and four right-angle plates 401 are selected, and other numbers of g...

Embodiment 3

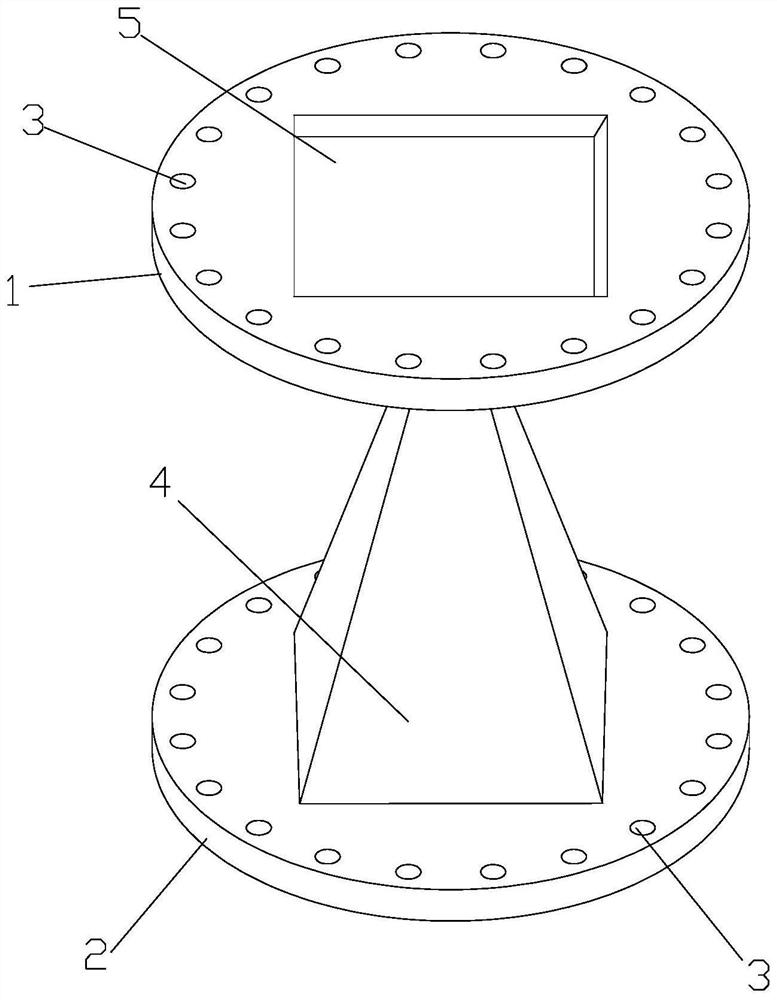

[0033] A helicopter tower positioning device, comprising a main disc 2 and an auxiliary disc 1, the main disc 2 and the auxiliary disc 1 are solid discs, the auxiliary disc 1 is provided with a positioning hole 5, and the main disc 2 is provided with a quadrangular pyramid-shaped positioning device. The protruding structure 4 and the positioning protruding structure 4 are used to engage with the positioning hole 5 . In this embodiment, a quadrilateral positioning hole 5 and a quadrangular pyramid-shaped positioning protrusion structure 4 are selected. In other embodiments, a triangular positioning hole and a triangular pyramid-shaped positioning protrusion structure can also be used, and the positioning holes can also be an even number. number of polygonal holes, and the number of edges of the polygonal pyramid is consistent with the number of sides of the positioning hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com