Pipe string and completion method

A pipe string and oil pipe technology, which is applied in the field of oilfield development, can solve problems such as low work efficiency, and achieve the effect of improving work efficiency and saving operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

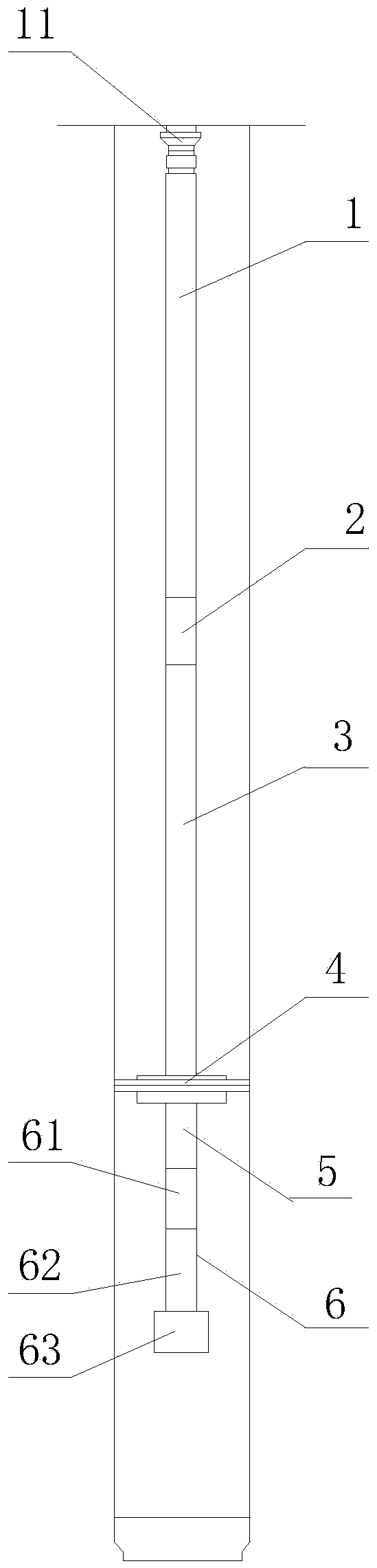

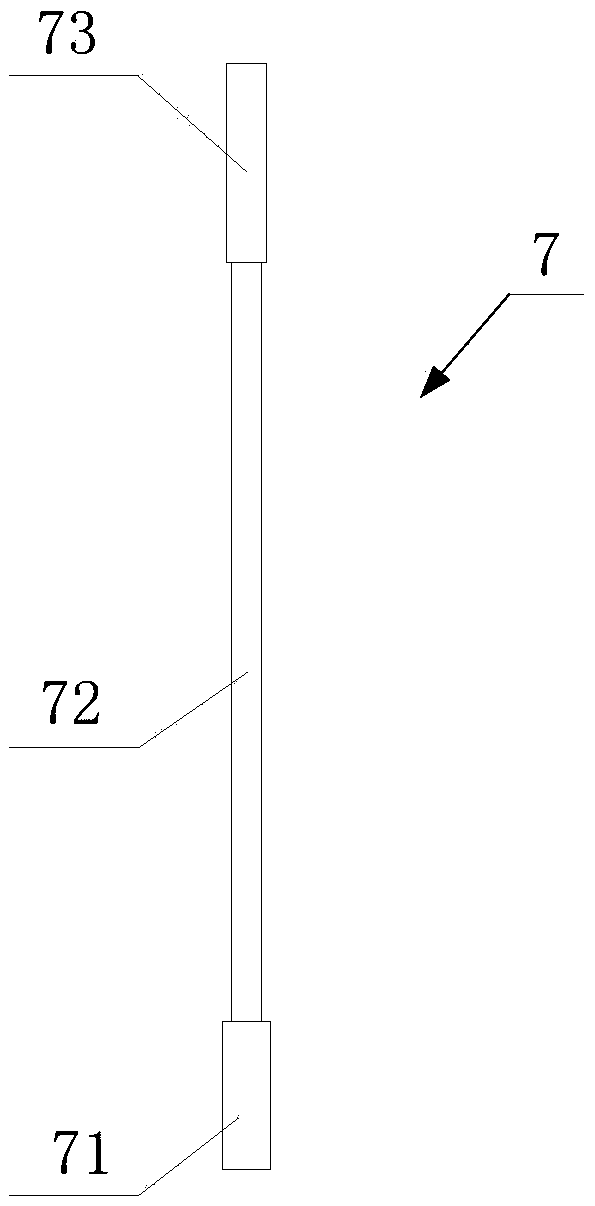

[0053] figure 1 It is a schematic structural diagram of a fixed pipe string assembly in a pipe string provided by an embodiment of the present invention. figure 2 A schematic structural diagram of an oil well pump assembly in a pipe string provided by an embodiment of the present invention. Refer to attached figure 1 And attached figure 2 As shown, this embodiment provides a pipe string, which is mainly used for well completion and oil recovery operations in oil field development. The pipe string includes: a fixed pipe string assembly and an oil well pump assembly 7, wherein:

[0054] The fixed tubing string assembly includes: a first oil pipe 1 , a pump base 2 , a second oil pipe 3 , a packer 4 , a third oil pipe 5 and a sand control device 6 arranged in sequence from top to bottom.

[0055] Specifically, the top end of the first oil pipe 1 is located at the wellhead, and the bottom end of the first oil pipe 1 communicates with the top end of the pump base 2 . The bott...

Embodiment 2

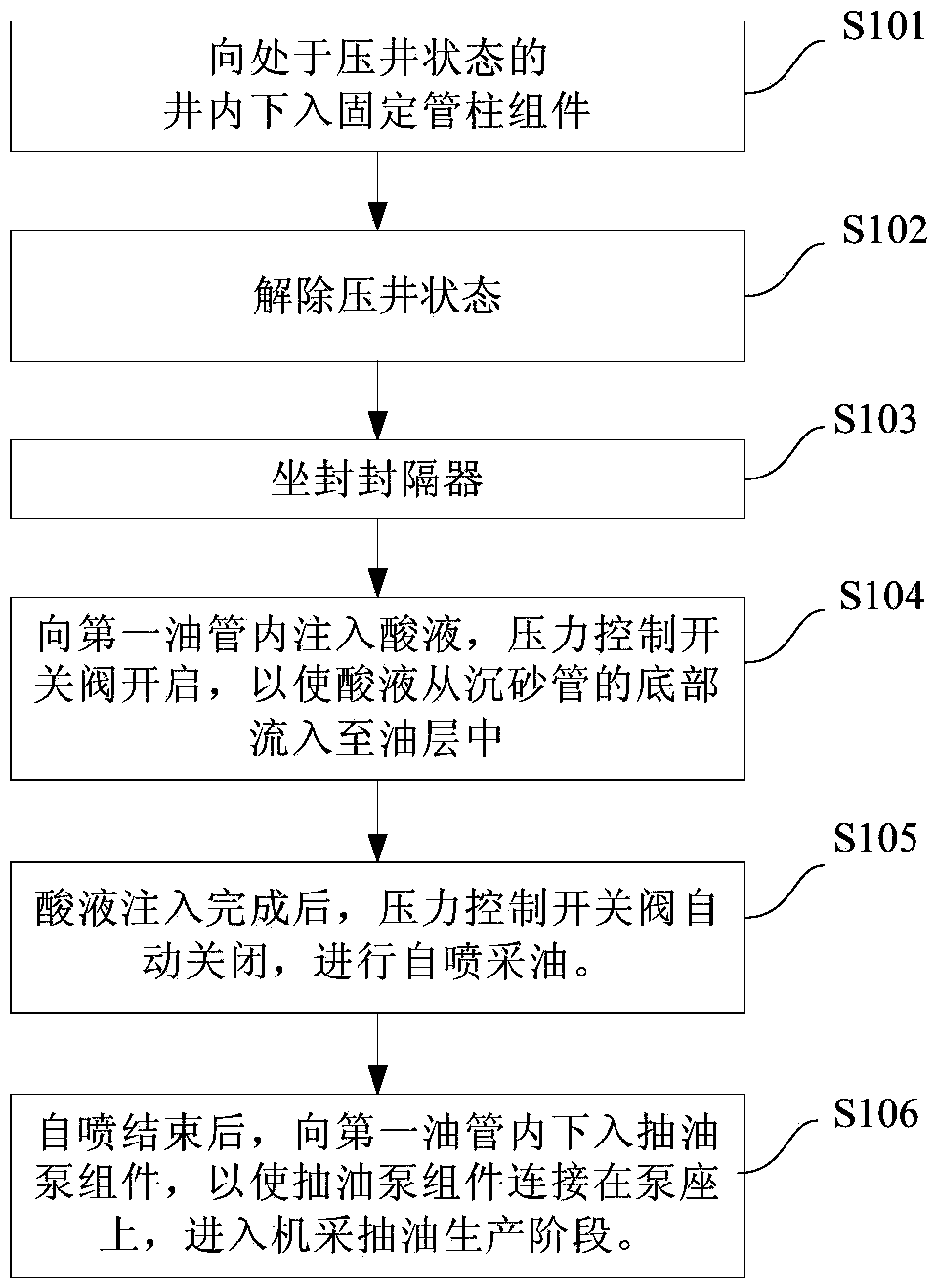

[0086] This embodiment provides a well completion method, which is completed by using the pipe string provided in the above embodiment.

[0087] image 3 For the schematic flow chart of the well completion method provided in this embodiment, refer to the attached image 3 As shown, a well completion method utilizing the above pipe string for well completion includes:

[0088] S101, run the fixed pipe string assembly into the well in the kill state.

[0089] Specifically, the killing state refers to the injection of dense mud into the well to equal or slightly higher than the pore pressure of the formation, so as to suppress the energy of the formation so that it cannot self-spray.

[0090] S102. Release the kill state.

[0091] Specifically, after the fixed string assembly is lowered, the annulus protection fluid with low density is injected into the annulus area formed between the casing and tubing in the well to replace the high-density kill mud in the wellbore to complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com