Rail limiting device of heavy railway mechanical platform platform plate

A technology of limiting device and platform plate, which is applied to railway fixtures, roads, tracks, etc., can solve the problems of high labor intensity of erectors, difficult to accurately align, and low operation efficiency, so as to improve operation efficiency and facilitate modularization. The effect of replacing and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and examples.

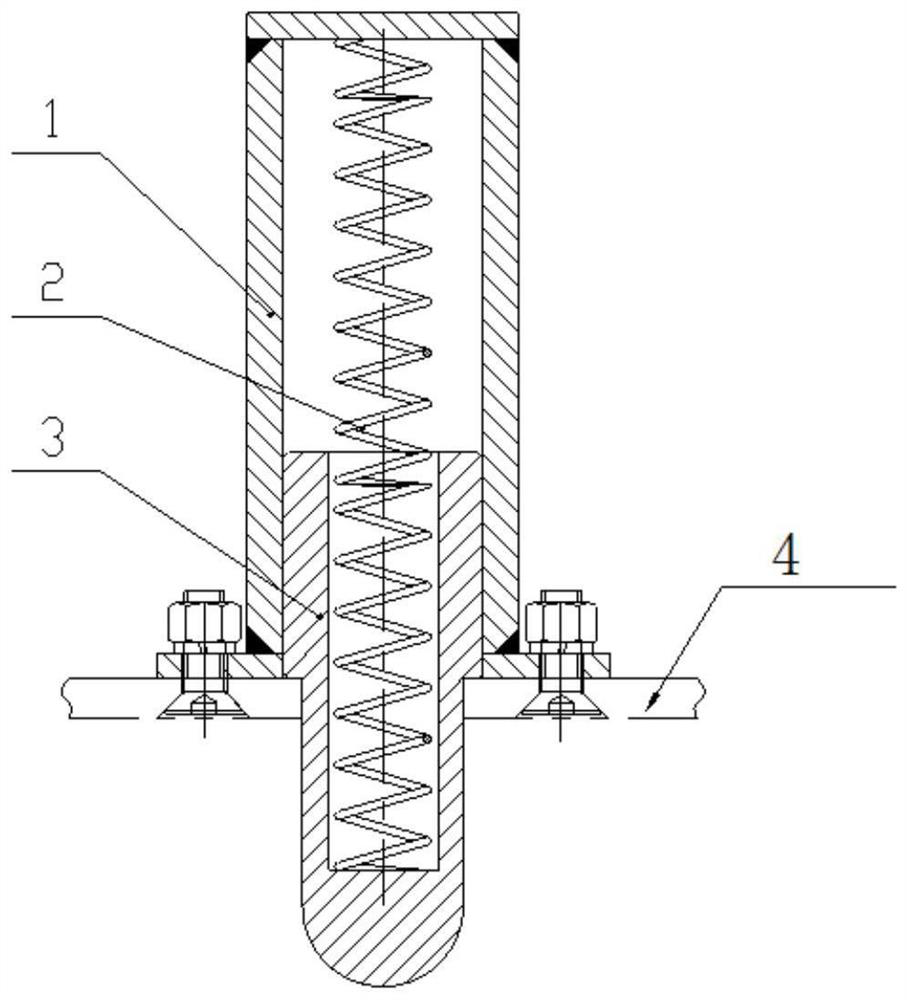

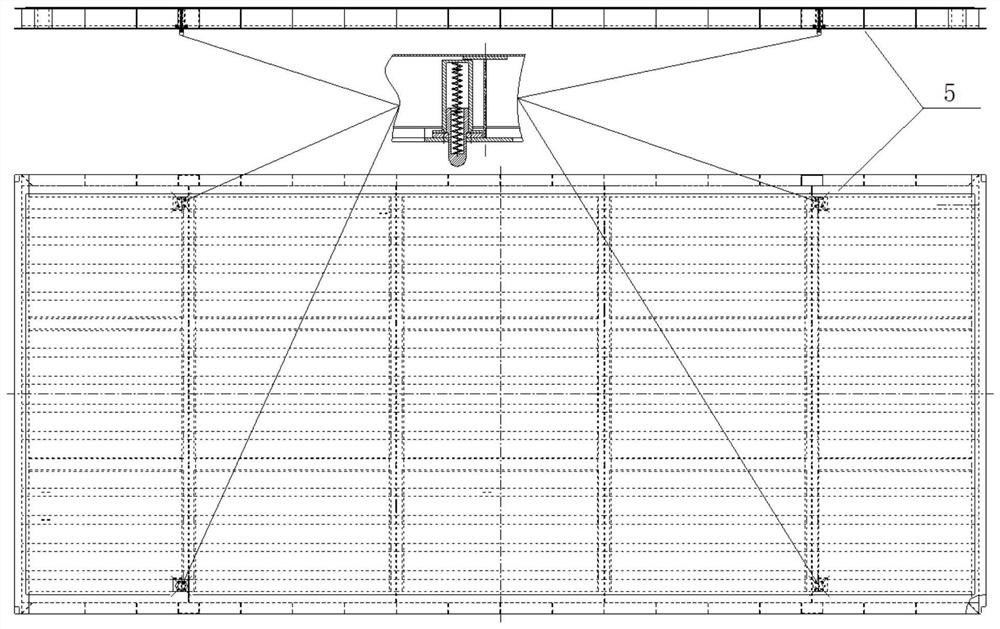

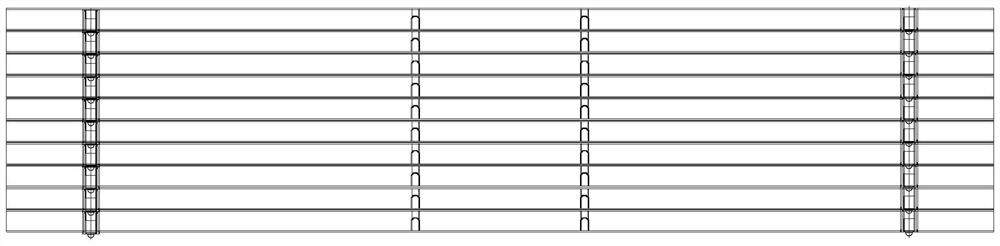

[0028] This embodiment provides a rail limit device for the platform slab of a heavy-duty railway mechanized platform, see the attached Figure 1-2 , the platform plate 5 includes an upper panel and a lower panel 4; more than two rail limiting devices are installed between the upper panel and the lower panel 4 of the platform plate 5; and the lower panel 4 is processed with The one-to-one corresponding limit holes of the rail limit devices;

[0029] See attached figure 1 , each of the rail limit devices includes: a guide cylinder 1, a guide shaft 3 and a spring 2;

[0030] The guide cylinder 1 is a cylindrical structure with one end closed and one end open. The open end of the guide cylinder 1 is provided with a flange, and the flange is provided with four light holes for installing bolts; the guide The cylinder 1 is located between the upper panel and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com