An elastic plate used for a battery plate set

A technology for electrode plates and batteries, which is applied to battery components, secondary batteries, and secondary battery gas removal. Drying ability, improve service life, prolong service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

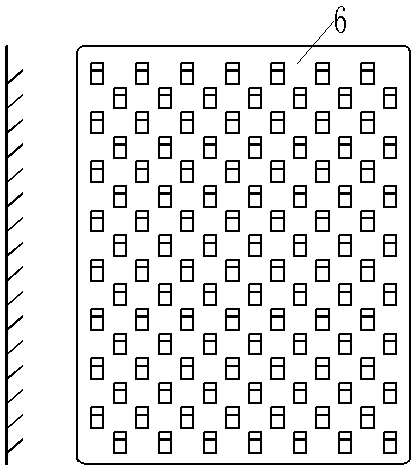

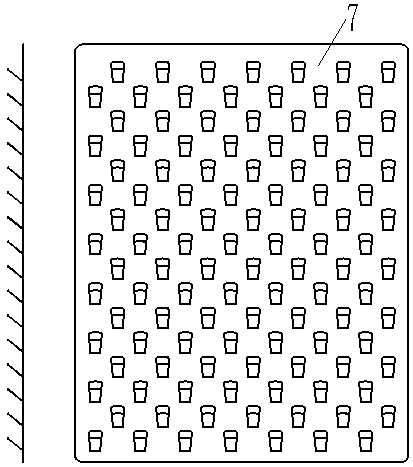

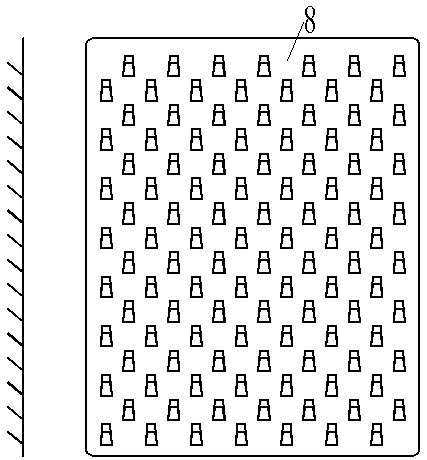

[0027] Such as Figure 1-7 As shown, a spring plate used in the battery plate group, the spring plate is arranged on one side or both sides of the pole plate group or between single or multiple adjacent pole plates 1 in the pole plate group, the spring plate The plate plane is porous, and the spring plate has springs or shrapnels that can automatically adjust the height according to the pressure. The spring board is made of elastic material, hollow plastic or corrugated plastic, or the spring board is partially punched or processed from an elastic steel plate.

[0028] The spring plate is a uniform multi-opening spring plate 2, a punched hollow plate 3 or a corrugated spring plate 4, and the spring plate is provided with at least one for discharging the precipitated gas of the plate and adding electrolyte and overlapping with the through hole of the plate. through-hole 5.

[0029] When the elastic plate is a uniform multi-opening elastic plate 2, a single uniform multi-openi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com