Electric power steering

A technology of electric power steering and electric motors, which is applied to electric steering mechanisms, power steering mechanisms, automatic steering control components, etc., can solve the problems of huge data volume and large memory usage, and achieve the effect of suppressing computing load and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

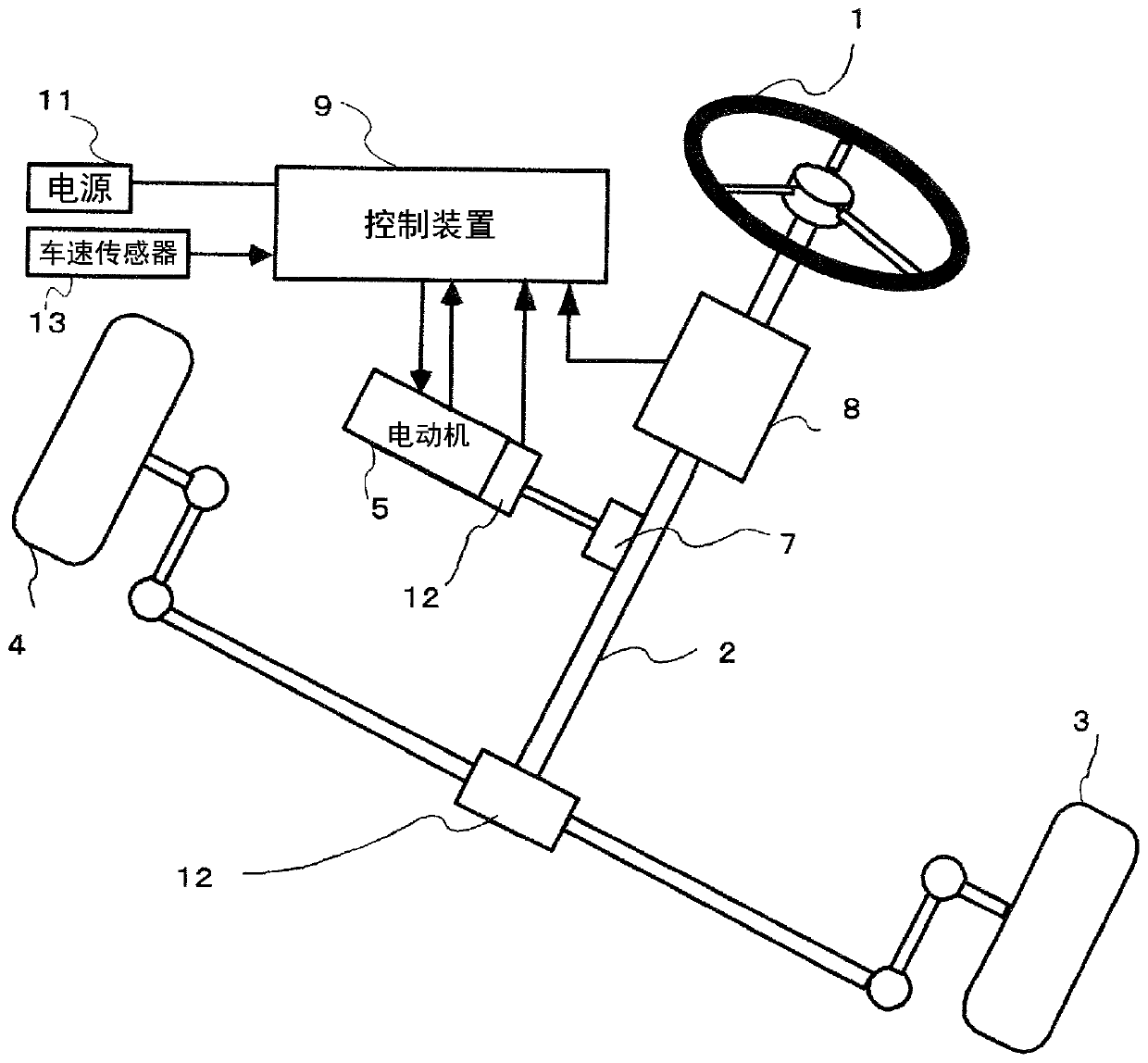

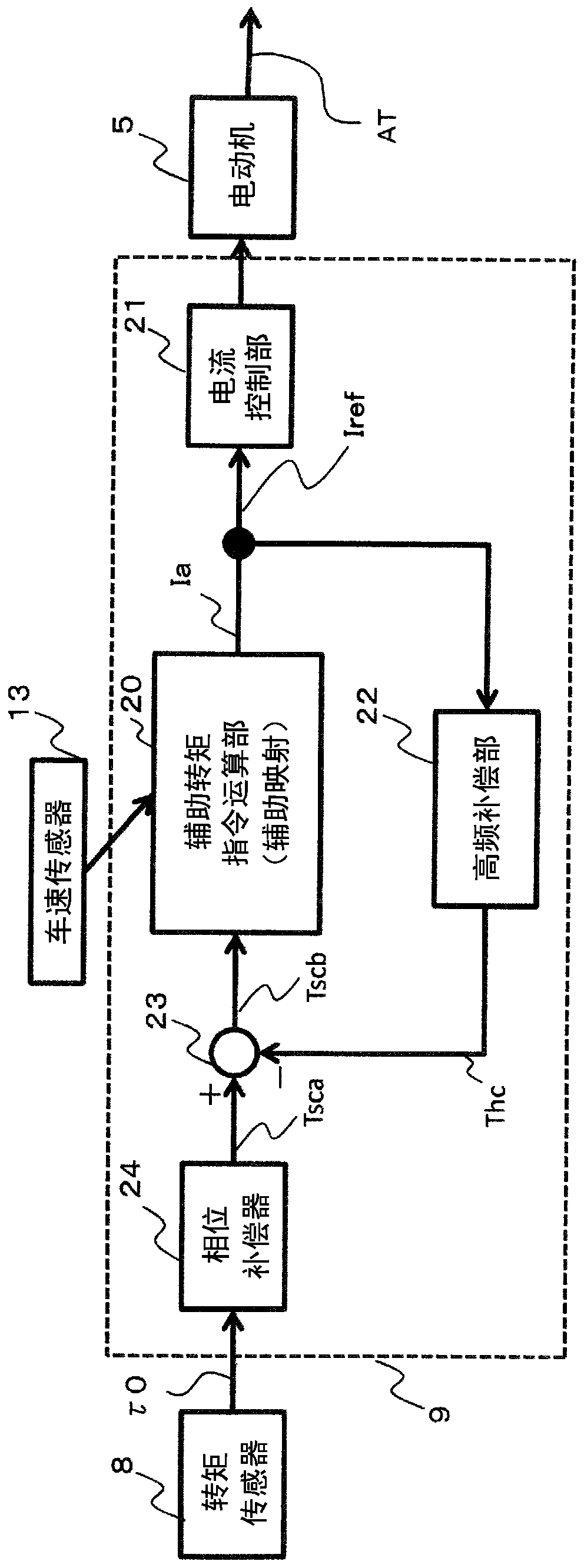

[0042] Next, an electric power steering device according to Embodiment 1 of the present invention will be described based on the drawings. figure 1 It is a configuration diagram showing the configuration of a steering system of a vehicle including the electric power steering device according to Embodiment 1 to Embodiment 5 of the present invention. figure 1 Among them, the steering system of the vehicle includes: the steering wheel 1 operated by the driver of the vehicle, the steering shaft 2 connected with the steering wheel 1, the rack and pinion mechanism 12 connected with the steering shaft 2, and the driver through the steering wheel 1, steering Wheels 3 and 4 that are steered by shaft 2 and rack and pinion mechanism 12.

[0043] Furthermore, the wheel steering system further includes the electric power steering device according to Embodiment 1 of the present invention. The electric power steering device includes: a motor 5 that generates assist torque for assisting the ...

Embodiment approach 2

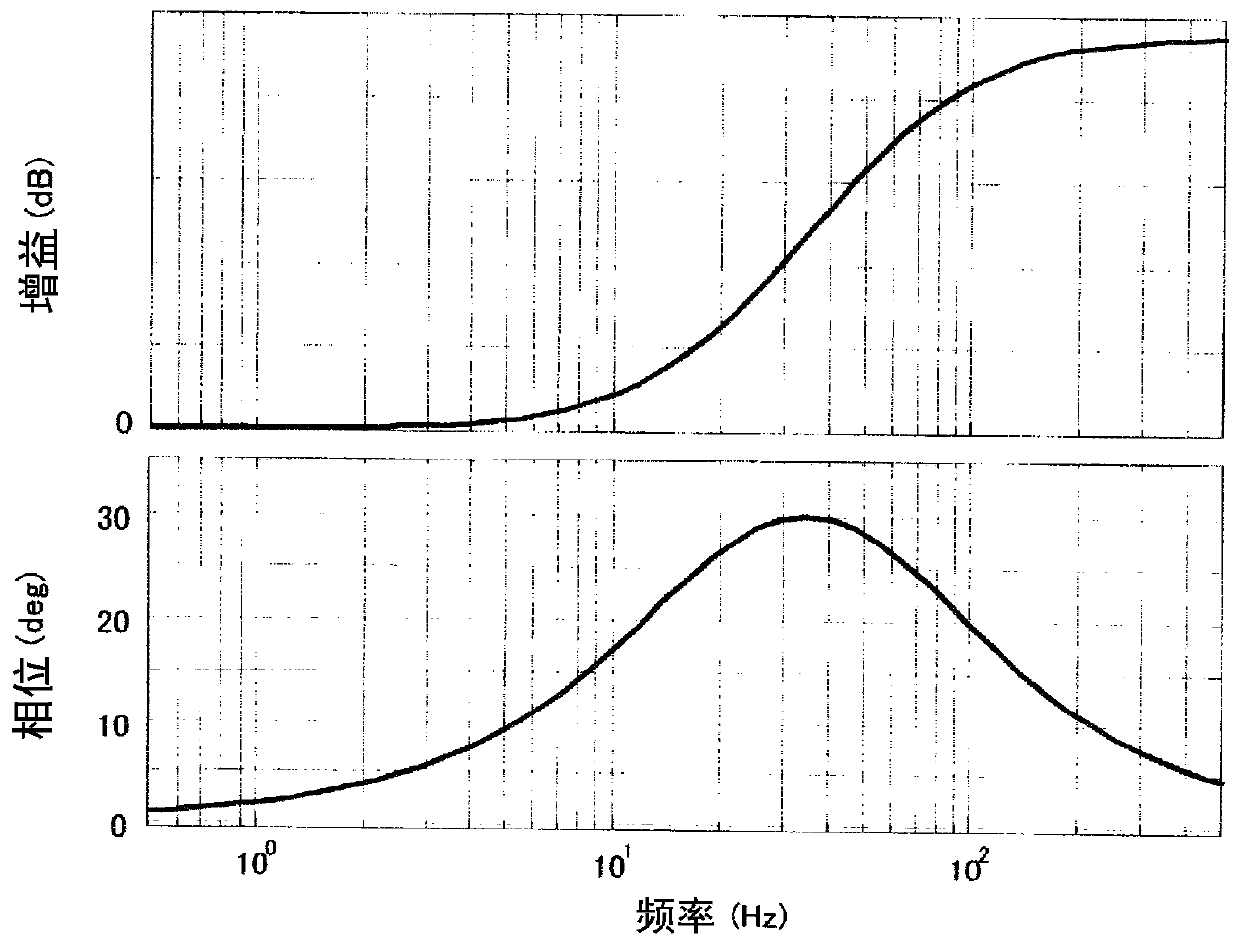

[0100] Next, an electric power steering device according to Embodiment 2 of the present invention will be described. Figure 10 It is a block diagram showing the structure of the control device in the electric power steering system according to Embodiment 2 of the present invention. The difference from the structure of Embodiment 1 above is that the subtractor 23 is changed to the adder 25 and the phase compensation is changed. The configuration of the first embodiment is the same as that of the first embodiment except for the settings of the frequency characteristics of the device 24 and the high-frequency compensator 22 . In the following description, the differences from the configuration of Embodiment 1 will be mainly described.

[0101] The phase compensator 24 performs phase compensation for decreasing or increasing the high-frequency gain on the steering torque signal τ0 detected by the torque sensor 8 to obtain a compensated steering torque signal Tsca. The phase comp...

Embodiment approach 3

[0130] Next, an electric power steering device according to Embodiment 3 of the present invention will be described. Figure 15 It is a block diagram showing the configuration of a control device in the electric power steering system according to Embodiment 3 of the present invention. The difference from the configuration of the above-mentioned second embodiment is that the phase compensator 24 in the second embodiment is replaced with the phase compensator 27 as the second phase compensator in the subsequent stage of the assist torque command calculation unit 20 . The adder 26 is the same as the adder 25 in the second embodiment. Other configurations are the same as those in Embodiment 2. In the following description, differences from Embodiment 2 will be mainly described.

[0131] Figure 15 , the frequency characteristic of the phase compensator 27 is the same as that of Embodiment 2 Figure 11 The frequency characteristics of the illustrated phase compensator 24 are th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com