Power Systems

A technology of power supply system and power supply, which is applied in the field of power supply system, can solve problems such as voltage reduction of smoothing capacitors, achieve the effect of reducing the number of parts and suppressing the increase in cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

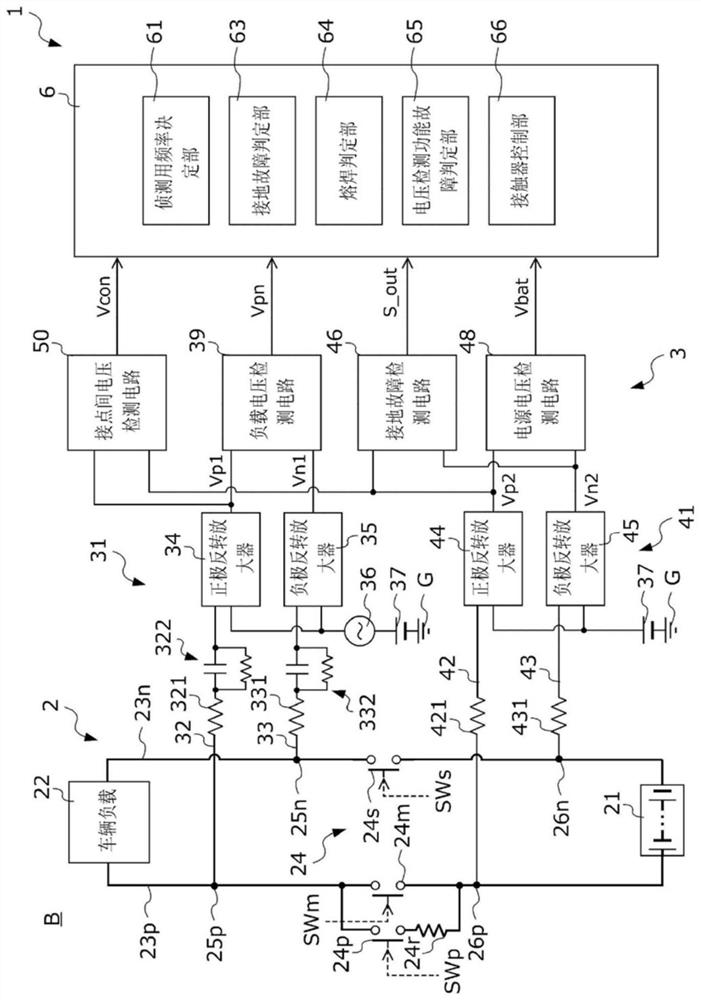

[0083] In the following, on the one hand, refer to the appendix Figure 1 A first embodiment of the present invention will be described in terms of this aspect.

[0084] figure 1 It is a figure which shows the structure of the power supply system 1 of this embodiment. The power supply system 1 is mounted on a vehicle body B of an electric vehicle such as a battery-driven vehicle, a hybrid vehicle, and a fuel cell vehicle.

[0085] The power supply system 1 includes a non-grounded circuit 2 , a state detection circuit 3 that is connected to the non-grounded circuit 2 and generates various signals according to the state of the non-grounded circuit 2 , and controls the non-grounded circuit 2 and the state detection circuit 3 . Electronic control unit 6 (hereinafter, abbreviated as "ECU 6").

[0086] The non-grounded circuit 2 includes a power source 21 for generating high voltage direct current, a vehicle load 22 , a positive high-voltage power line 23 p connecting the positiv...

no. 2 approach >

[0159] Next, on the one hand, refer to the appendix Figure 1 A second embodiment of the present invention will be described in terms of this aspect.

[0160] Figure 11 It is a figure which shows the structure of 1 A of power supply systems of this embodiment. In the above-described first embodiment, the case where one power source 21 is connected to the vehicle load 22 has been described. On the other hand, the power supply system 1A of the present embodiment includes a plurality of ( Figure 11 The aspect of the power supply is different from the power supply system 1 of the first embodiment. In addition, in the following description, the same code|symbol is attached|subjected to the same structure as the power supply system 1 of 1st Embodiment, and the description is abbreviate|omitted.

[0161] The power supply system 1A includes a non-ground circuit 2A, a state detection circuit 3A, and an ECU 6A.

[0162] The non-grounded circuit 2A includes: a first power source 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com