Stamping mould for processing centre distance offset of needles in terminal

A technology of stamping die and center distance, which is applied in the field of stamping die for dealing with the deviation of the center distance of the needle in the terminal. , the effect of reducing bending stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

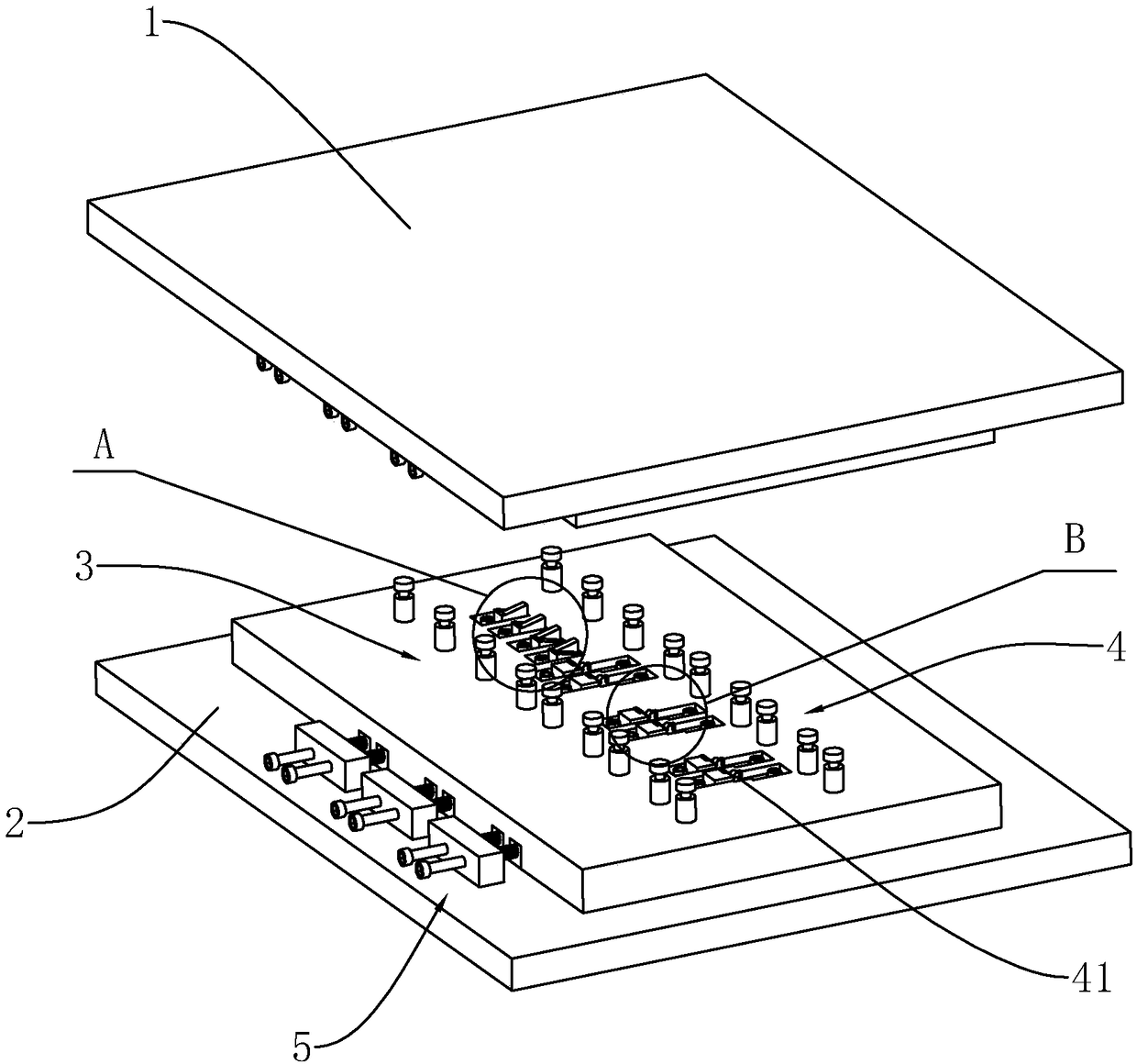

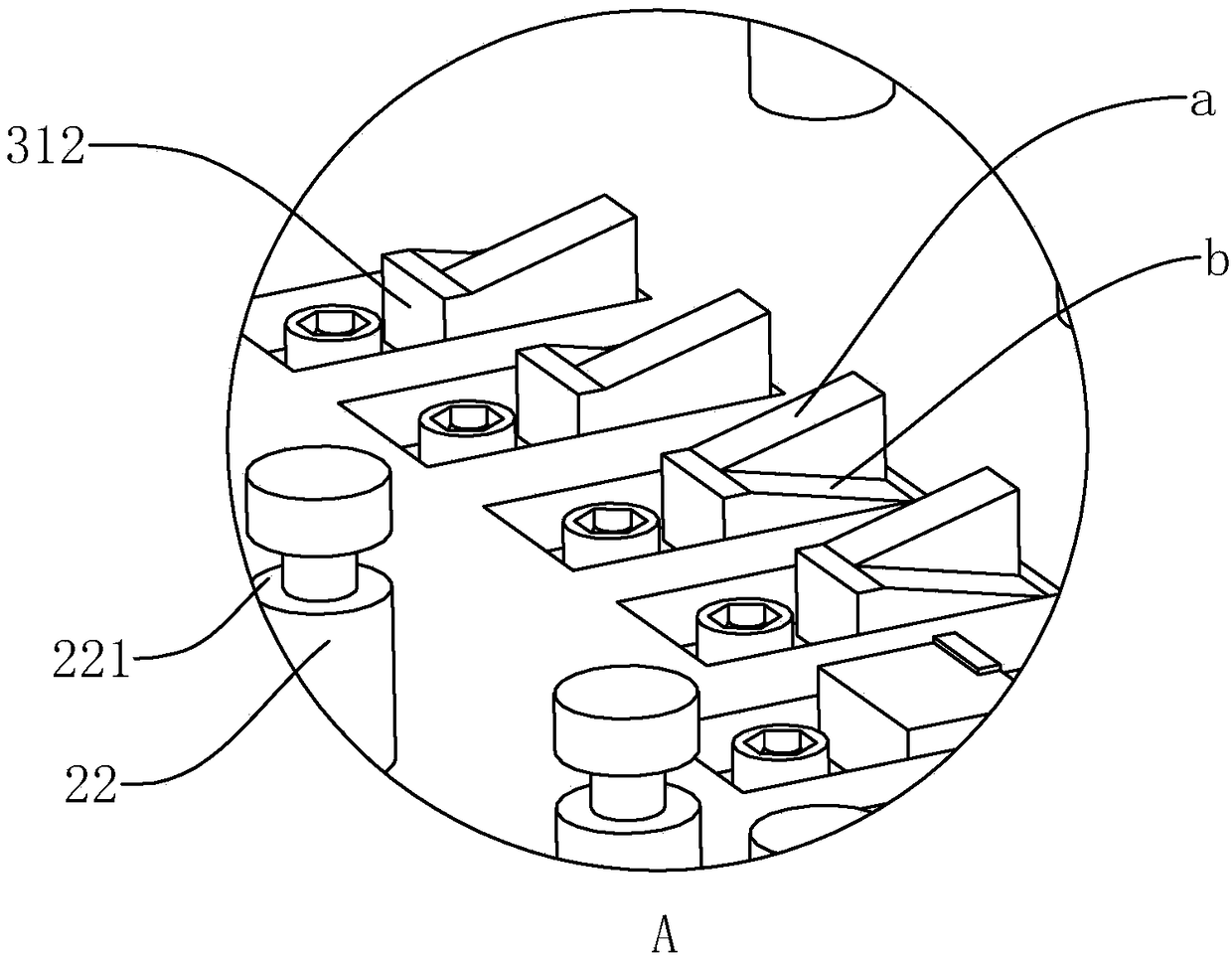

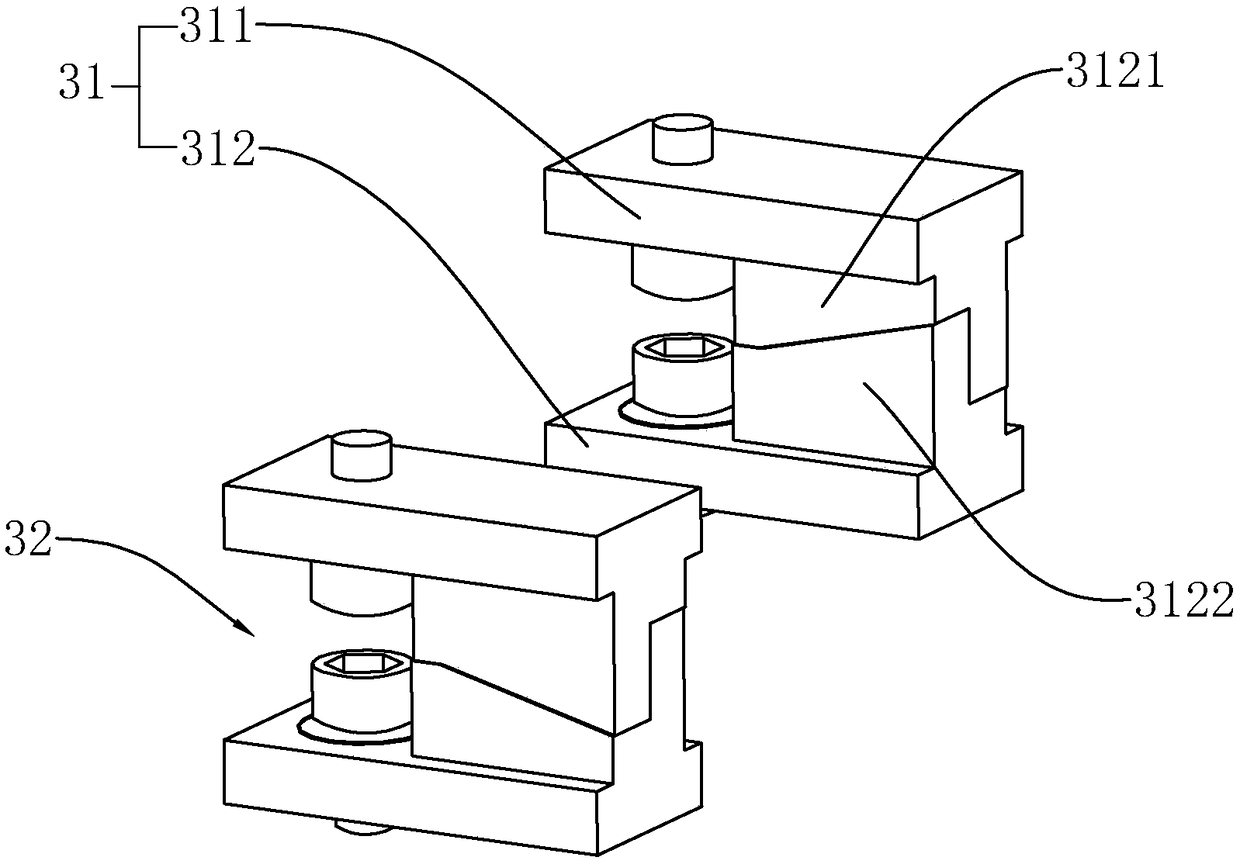

[0037] This embodiment discloses a stamping die for dealing with the deviation of the center distance of the pins in the terminal, such as figure 1 , figure 2 , image 3As shown, it includes upper template 1 and lower template 2. Connecting pieces are usually processed and manufactured in batches, and the intermediate product is a long string of multiple connecting pieces connected in parallel. The long string of connecting pieces enters from one end between the upper template 1 and the lower template 2, and is sent out from the other end after punching. The upper template 1 and the lower template 2 are provided with a bending area 3 and an adjustment area 4 in turn on the conveying path of the connecting piece, and the bending area 3 is provided with a first bending assembly 31 and a second bending assembly for bending the needle body. Two bending compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com