Bottom pouring type purification smelting device and method

A smelting device, bottom-injection technology, applied in the field of bottom-injection purification and purification smelting device, can solve the problems of pollution, high content of harmful gas, low quality of alloy melt, etc., reduce cost, reduce inclusion defects, and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

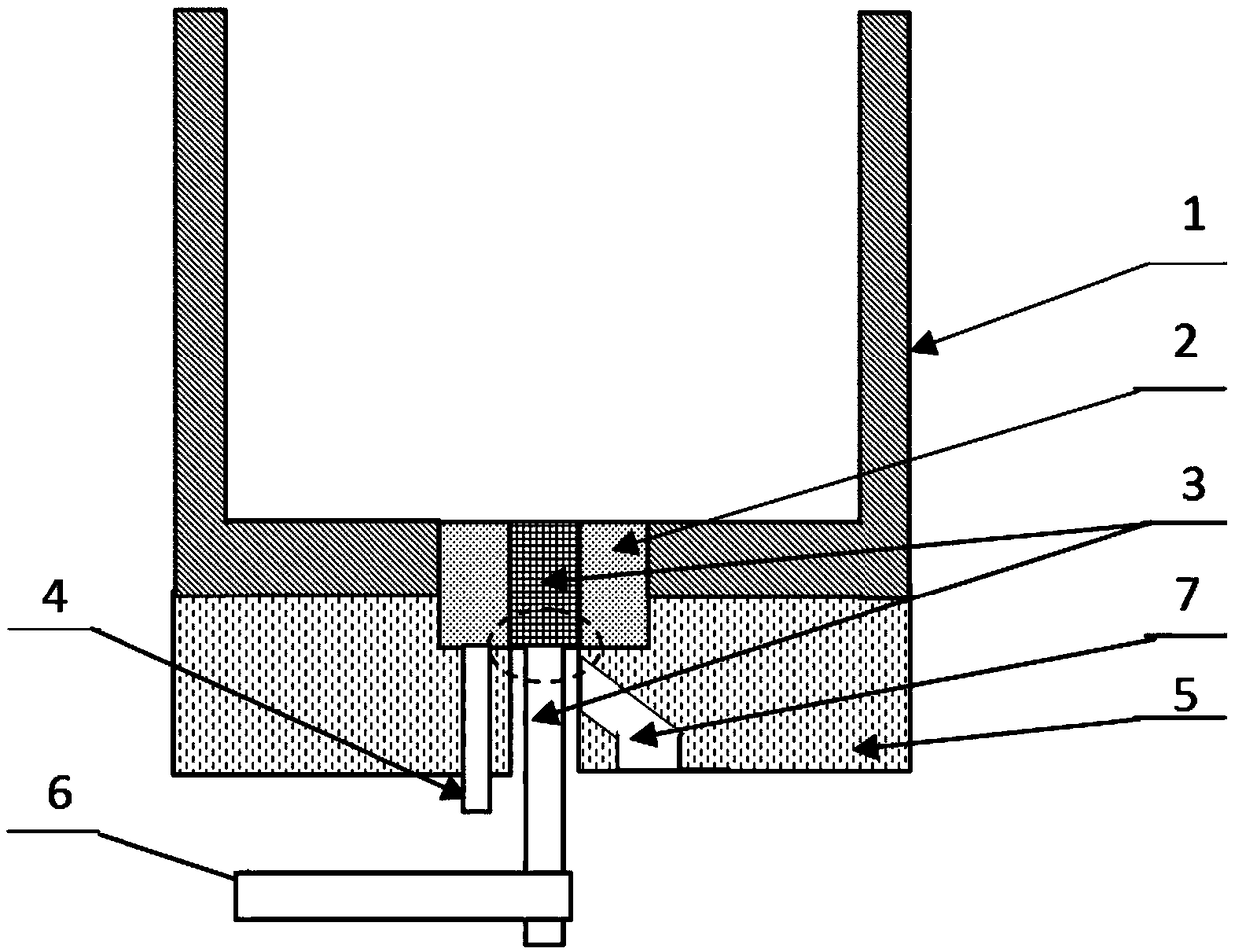

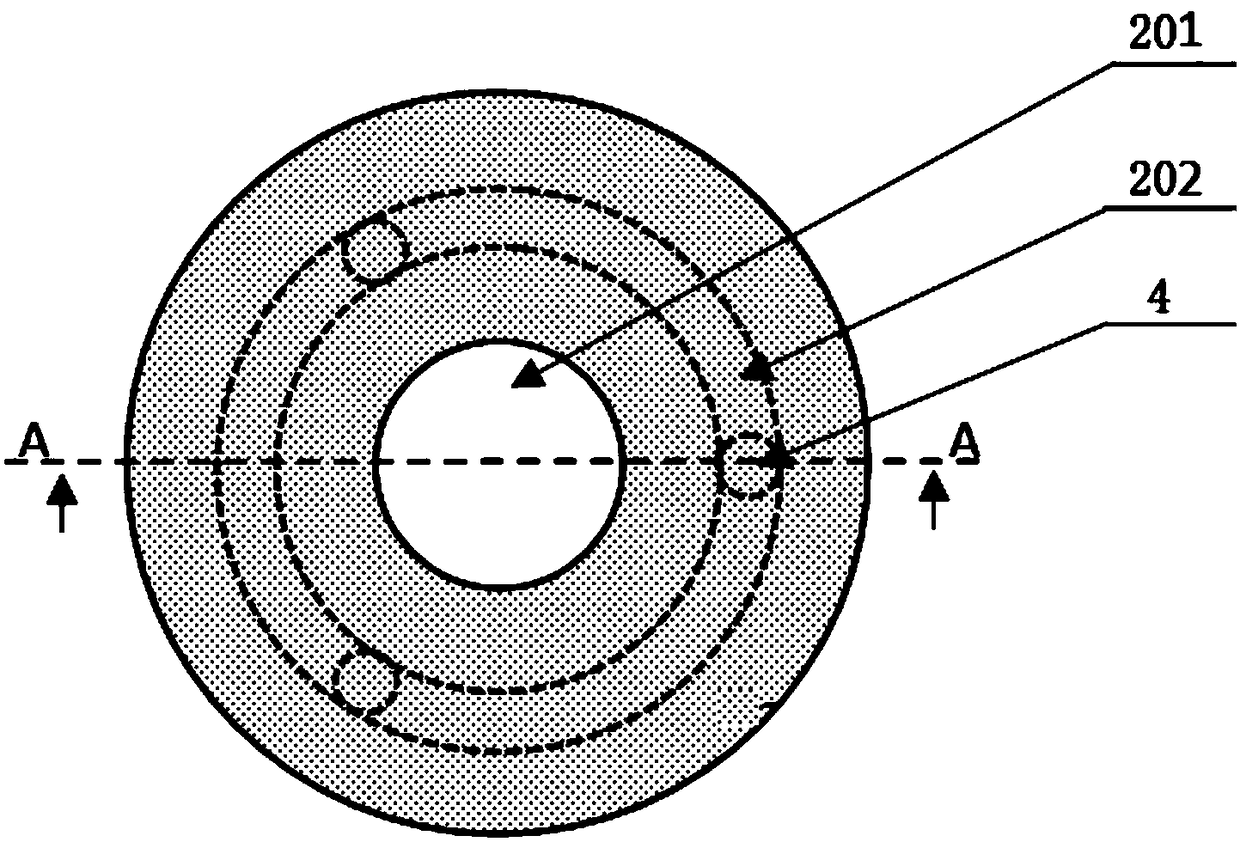

[0045] Use the smelting device to carry out the bottom pouring purification and purification smelting method, wherein, the bottom pouring device in this embodiment is figure 1 The shown rod-shaped drawing device, the method comprises the steps of:

[0046] (1) Before alloy smelting, connect the bottom blowing argon device to the bottom of the ladle or crucible, and insert the ceramic stopper rod of the rod-shaped drawing device in the middle of the bottom blowing argon device;

[0047] (2) The melted alloy melt is first subjected to high-temperature refining in the ladle or crucible 1 at a temperature of 100-150°C above the melting point of the alloy, and the refining time is generally 10-30min to initially remove impurities and harmful gases in the melt;

[0048] (3) After the alloy is refined, open the inlet valve on the argon gas inlet pipe, pass the argon gas from the argon gas inlet pipe into the bottom blowing argon device and send it into the alloy melt, and the argon g...

Embodiment 2

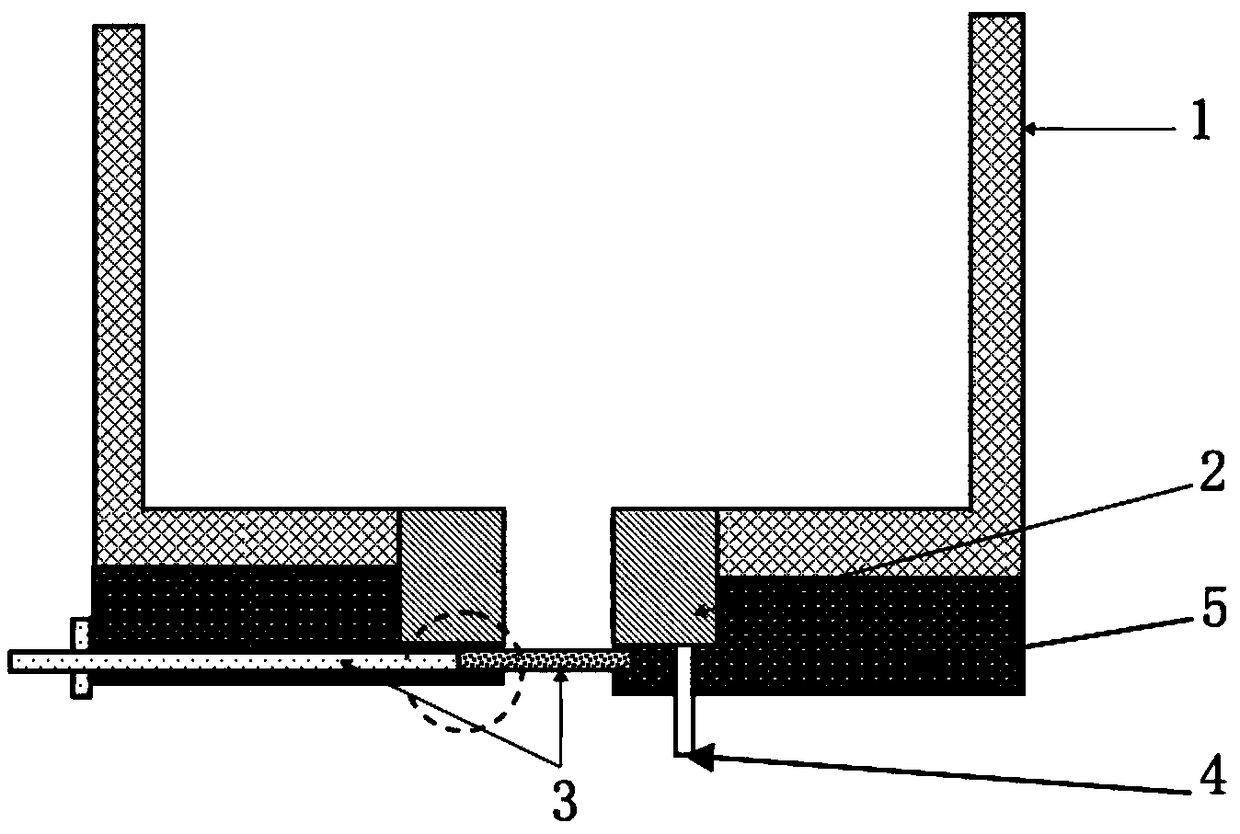

[0052] Use the smelting device to carry out the bottom pouring purification and purification smelting method, wherein, the bottom pouring device in this embodiment is figure 2 As shown in the drawing device, the method comprises the steps of:

[0053] (1) Before smelting steel, superalloy or other alloys, connect the bottom blowing argon device at the bottom of the ladle or crucible, and move the isolation plate of the drawing device to the bottom of the bottom blowing argon device;

[0054] (2) After the alloy is melted, heat it up to 100-150°C above the melting point of the alloy for high-temperature refining of the melt, and the refining time is 10-30 minutes.

[0055] (3) Open the argon gas inlet valve, send the argon gas into the melt from the bottom through the breathable brick, make it gradually rise from the bottom to the liquid level, adjust the argon gas pressure to 0.1MPa-0.6MPa, and the purification time is 10- 20min.

[0056] (4) When the melt temperature meets...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com